Passivation Services

Protect your critical metal components from corrosion with Element's comprehensive passivation testing services. Our expert teams provide end-to-end convenience, rapid turnaround times, and hands-on technical guidance to ensure your materials meet rigorous industry standards. Whether you're in aerospace, defense, automotive, or oil and gas, we deliver customized solutions that safeguard your products' integrity.

What is Passivation Testing at Element?

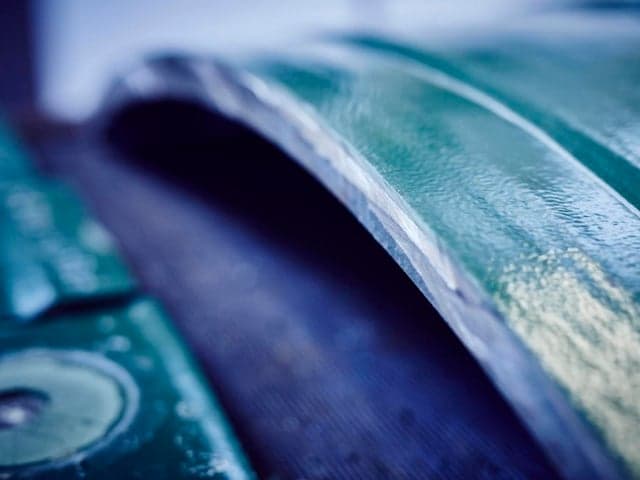

Passivation is a specialized chemical process that creates a protective oxide layer on metal surfaces to prevent corrosion, much like the natural oxidation process seen in copper. At Element, we provide comprehensive passivation testing services with nearly 190 years of materials testing expertise to verify this protective treatment meets your industry's standards and effectively shields your components from environmental damage.

What Can Element Offer You For Passivation Services?

Key tests offered

Key tests offered

We perform comprehensive passivation testing to various industry specifications, delivering results that help you meet regulatory requirements with confidence. Our testing capabilities include:

- Verification of protective oxide layer effectiveness

- Corrosion resistance evaluation

- Compliance testing to aerospace, defense, automotive, and oil and gas standards

Components and materials we test

Components and materials we test

Partner with us to protect your metal components and alloys across aerospace, defense, automotive, oil and gas, and other commercial applications. Our passivation testing verifies the effectiveness of corrosion protection treatments, helping ensure your products maintain their integrity throughout their lifecycle while providing the expert guidance you need to select the optimal process for your specific materials.

Methods and solutions offered

Methods and solutions offered

Our chemical processing services provide the end-to-end convenience you need, from process selection to final verification. We offer:

- Customized passivation treatments designed for your specific materials and applications

- Expert consultation to help you decide which process is most beneficial for your materials

- Unique treatment plans designed to best suit your needs

- Rapid turnaround times to keep your projects on schedule

The passivation process works similarly to the natural oxidation process seen in copper, applying a controlled protective oxide layer to your material's surface that actively prevents rust and other defects from developing. This engineered approach ensures consistent protection across your components.

Which labs offer this service

Which labs offer this service

Our nearly 190-year heritage in materials testing, combined with our 8,500-strong global team, provides you with unmatched expertise and convenience.

Standards we test to and materials we test

American Metals Society:

- AMS-STD-753

- AMS 2700

- AMS-QQ-P-35

American Society for Testing & Materials:

- ASTM A380

- ASTM A967

- ASTM F1089

Military Standards:

- MIL-S-5002

- MIL-STD-753

We test a comprehensive range of metal components and alloys across multiple sectors:

- Stainless steel components and fasteners

- Titanium alloys and aerospace parts

- Nickel-based superalloys

- Aluminum components

- Specialty metal alloys for defense applications

Your Challenges, Our Solutions

Corrosion Risk Management

Complex Standards Compliance

Process Selection Uncertainty

Speed and Convenience Needs

Why Choose Element

Nearly 190 Years Heritage

End-to-End Convenience

Hands-On Technical Guidance

Rapid Turnaround Times

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Sour Service Corrosion Testing for NACE MR0175/ISO 15156 Compliance

Element provides industry-leading sour service corrosion testing, helping oil and gas companies mitigate corrosion risks, comply with NACE MR0175/ISO 15156, and enhance material reliability in challenging environments.

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Chemical Processing Services

Expert chemical processing services tailored for testing and post-production treatment. Advanced methods meet critical engineering standards, minimising errors while ensuring reliable, high-quality results.

Paint and Coating Testing Services

Get reliable paint & coating testing services to verify durability, ensure compliance, and reduce defects. Fast, integrated solutions tailored to your industry.