Residual Stress Measurement

Protect your critical components from unexpected failures with comprehensive residual stress measurement services. Our advanced testing methods help you identify potential stress-related issues before they impact your operations. Whether you need on-site testing or laboratory analysis, we deliver quantitative, high-precision measurements to keep your materials and products safe.

What is Residual Stress Testing at Element?

Residual stress occurs when materials retain internal stresses from manufacturing processes like fabrication, heat treatment, or welding. Excessive residual stress can lead to deformation, cracking, and premature failure, especially in load-bearing components. At Element, we measure these stresses using multiple advanced techniques to determine material safety and prevent failures. Our comprehensive testing helps ensure your materials remain fit for purpose throughout their lifecycle.

What can Element offer you for residual stress measurement?

Key tests offered

Key tests offered

We offer several tests for residual stress measurement, helping to ensure that the materials used in aerospace, construction, transportation, and other critical industries are safe and fit for purpose:

- Strain Gaging (ASTM E837 - Hole-Drilling Method) - Industry-standard technique to measure near-surface residual stresses using strain gages.

- X-Ray Diffraction (XRD) Analysis - A precise method to assess subsurface stress by analyzing atomic lattice spacing changes in crystalline materials.

- Barkhausen Noise Analysis (American Stress Tech Microscan) - A non-destructive technique for assessing residual stress in ferro-magnetic materials, ideal for components affected by grinding or machining.

- Custom Combined Testing Programs - Tailored multi-method approaches for complex materials or failure analysis.

- On-Site and Laboratory Testing - Flexible service delivery to accommodate both in-field and controlled lab environments.

Components and materials we test

Components and materials we test

Keep your critical components safe with our comprehensive testing services. Our experts specialize in identifying residual stress in various materials, including aerospace parts and construction materials, where manufacturing processes, heat treatment, machining, or welding may have caused internal stresses focusing on structural, pressure-bearing, and safety-critical components.

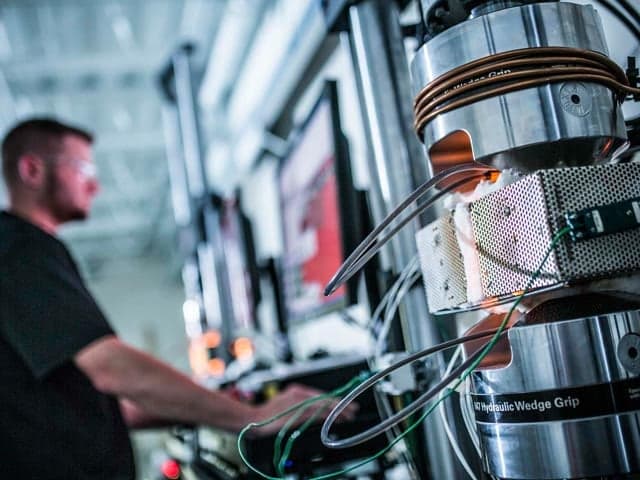

Cutting-edge equipment we use

Cutting-edge equipment we use

Our experts are continually assessing and improving our equipment and methodology. Currently, we use:

- High-resolution digital strain gages for precision stress mapping

- Advanced XRD diffractometers for quantitative stress analysis

- American Stress Tech Microscan for Barkhausen noise analysis

- Portable XRD systems for in-field stress evaluation

- State-of-the-art laboratory facilities with controlled environments for repeatable testing

Which labs offer this service?

Which labs offer this service?

Our team of experts operates from Materials Testing hubs around the world, including Europe, India, and the USA. This allows us to provide global access to our expert capabilities. We offer both in-house and on-site residual stress testing services at key locations worldwide. To find your nearest Materials Testing hub, please visit our Locations Page.

Standards we test to and products we test

- Aerospace components

- Construction materials

- Transportation components

- Machined parts

- Ferro-magnetic materials

Your Challenges, Our Solutions

Critical Failure Prevention

Manufacturing Process Verification

Material Safety Assurance

Complex Testing Requirements

Why Choose Element

Global Coverage, Local Service

Multiple Testing Methods

State-of-the-Art Facilities

Extensive Experience

Frequently asked questions

What causes residual stress in materials?

Residual stress can be caused by fabrication errors, heat treatment, welding, and processing operations such as milling, annealing, or machining.

When is residual stress measurement necessary?

Residual stress measurement is critical when you need to determine if materials are still safe for use, particularly after manufacturing processes or when external stresses are present. It's essential when stress levels may be approaching a material's yield strength.

Can multiple testing methods be combined for better results?

Yes. For complex failures or unique material requirements, our experts can create customized testing programs that combine multiple techniques, ensuring the most accurate stress analysis.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

X-Ray Diffraction (XRD) Analysis

X-Ray Diffraction (XRD) analysis is a non-destructive testing method that identifies crystalline phases and chemical composition, supporting precise material characterization for industries requiring detailed structural insights.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.