What is Hot Hardness Testing?

Have you ever wondered how materials can maintain their strength even when exposed to extreme heat? If so, then you might be interested in learning about hot hardness testing. It is a crucial tool that helps us uncover the secrets behind the resilience of materials in elevated temperature conditions. In this guide, we will explain the concept of hot hardness in simple terms, and provide practical insights and expert advice from Dr. John Tartaglia that can help you make informed decisions about the durability and performance of materials.

What is Hot Hardness Testing?

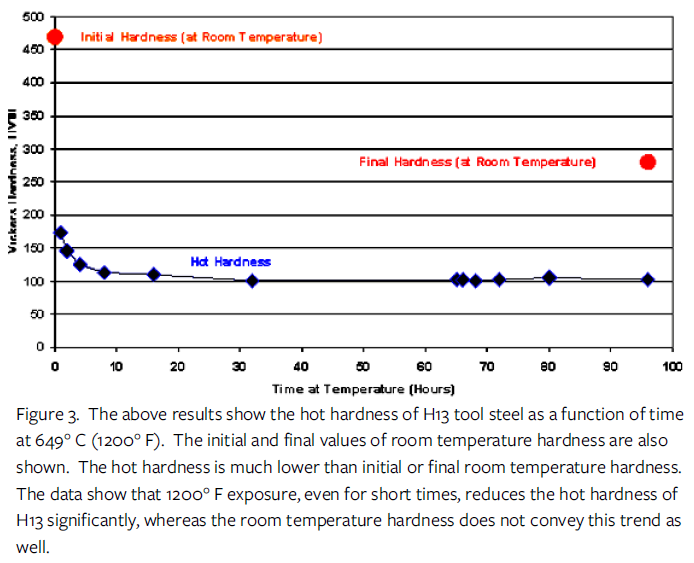

Hot hardness testing is the measurement of material hardness while at elevated temperature. Hot hardness can be valuable for assessing and comparing materials, such as tool steels and wear resistant coatings, which are used in high temperature applications such as valve seats and dies. Because room temperature hardness changes relatively little after high temperature exposure, it cannot be used to assess high-temperature properties. However, hardness-at-temperature changes significantly and reflects high temperature properties such as resistance to high temperature wear, erosion, indentation, plastic deformation, tempering, aging and creep.

What are the Benefits of Hot Hardness Testing?

Hot hardness testing is a method that offers several advantages, especially for industries that operate in high-temperature environments. Firstly, it is a rapid and cost-effective way to characterize materials, as multiple temperatures and exposure times can be tested in a single run. This allows for a quick comparison of different materials at elevated temperatures.

Secondly, hot hardness testing is an essential quality control measure for industries such as aerospace and automotive, where materials are frequently exposed to high temperatures during manufacturing or usage. The ability to maintain hardness and strength at elevated temperatures is crucial in these sectors, and hot hardness testing helps manufacturers to verify the suitability of materials for such critical applications.

Hot hardness testing plays a vital role in predictive maintenance strategies for equipment operating in high-temperature environments. Components exposed to high temperatures can degrade over time, leading to performance issues and downtime. By understanding how materials behave under such conditions, hot hardness testing can provide valuable insights into expected lifespan and performance degradation of components, enabling manufacturers to plan proactive maintenance interventions. This ensures continuous operational efficiency by identifying potential issues before they escalate and supports efficient maintenance planning.

How does Element conduct hot hardness testing?

Element is the only commercial laboratory that has hot hardness testing capability. Element conducts hot hardness testing similarly to normal Vickers hardness testing, except that the test is conducted inside a vacuum chamber at an elevated temperature.

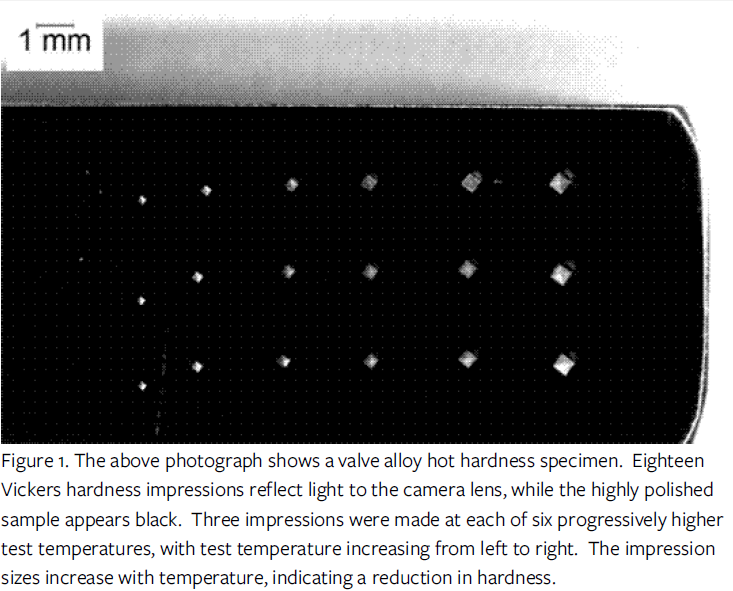

Samples measuring 25 by 9.5 by 9.5 mm (1 inch by 3/8 inch by 3/8 inch) are metallographically polished to a 1 μm finish to prepare them for testing. As many as three samples are inserted into the hot hardness test chamber and evacuated to 10-6 torr to prevent sample oxidation at high temperatures.

Resistance elements heat the chamber while thermocouples monitor the temperature of each sample. Each test temperature is stabilized for at least 5 minutes prior to making Vickers hardness impressions, although exposure times up to multiple hours are quite possible. Three Vickers impressions are made on each sample using a 10 kg load, then the chamber is heated to the next higher temperature in the series and the impression sequence is repeated.

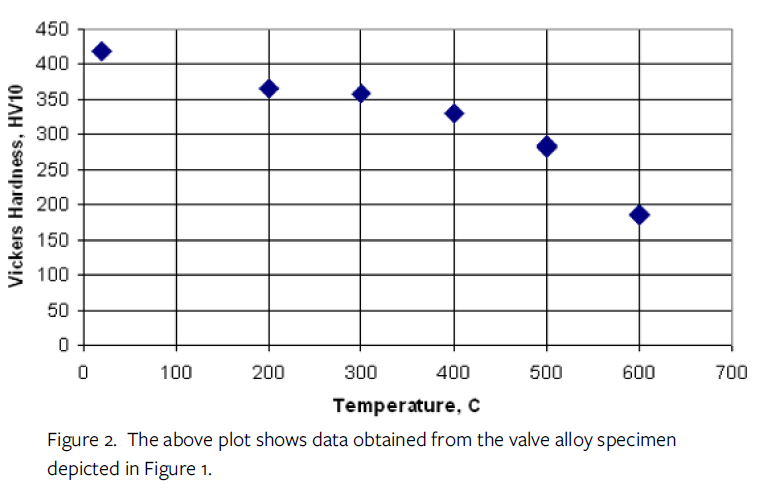

Element can conduct Vickers macrohardness testing at room temperature and at elevated temperatures from 175 to 870°C (350 to 1600°F); as many as 8 temperatures can be tested on each sample. After the samples have cooled, an Element expert removes them from the chamber, measures the diagonal lengths, and computes Vickers macrohardness using a formula from the ASTM E92 test method.

A typical tested sample is shown in Figure 1 and typical hot hardness data are shown in Figure 2.

Conclusion

In conclusion, hot hardness testing plays a crucial role in evaluating the performance of materials under high-temperature conditions. By understanding how materials behave at elevated temperatures, engineers and scientists can develop more robust and reliable products for various industries. Element's expertise in hot hardness testing enables companies to assess the suitability of materials for specific applications and make informed decisions that enhance product quality and performance. As technology continues to advance, the demand for materials capable of withstanding extreme temperatures will only grow, making hot hardness testing an indispensable tool in the field of materials science and engineering.

To find out more about our hardness testing services or to request a quote, please contact us today,