Shear Testing

Gain accurate insights into your materials' performance under parallel force with our comprehensive Shear Testing services. Whether evaluating adhesive bonds, characterizing directional composite properties, or qualifying fasteners, our experts deliver precise data across various temperature conditions while guiding you through method selection. With experience handling complex, custom testing requirements, we help you develop safer, more reliable products that meet rigorous standards while providing quick turnaround for your critical applications.

What is Shear Testing at Element?

Shear testing evaluates how materials perform when force is applied in a parallel direction, causing sliding failure along a flat plane. At Element, we provide comprehensive shear testing across various materials, including metals, adhesives, and composites. Our testing determines the point at which a sample fails (shear strength), providing critical data for material selection, quality control, and ensuring performance under real-world conditions.

What Can Element Offer You For Shear Testing?

Key tests offered

Key tests offered

Access a comprehensive range of shear testing methods tailored to your specific material needs, whether you're developing new products or validating existing ones. Our specialized testing capabilities deliver precise performance data that helps you make informed decisions about material selection and design optimization. We adapt our testing approaches to address your unique requirements and industry standards.

- Single and double lap shear testing for adhesives

- In-plane shear testing for layered composites

- Short beam shear testing for interlaminar strength

- V-notch shear testing for directional strength evaluation

- Interlaminar shear strength testing (ASTM D2344)

Specialized composite testing expertise:

Unlike isotropic metals, composites exhibit highly directional shear properties not related to their tensile characteristics. Our composite testing experts help you navigate these complexities, selecting the optimal test method for your specific material structure and application requirements. We've tested thousands of composite specimens and understand the precision required in sample preparation and fixture alignment to obtain reliable results that accurately represent your material's true performance under real-world conditions.

Materials and components we test

Materials and components we test

Your critical components deserve thorough evaluation against real-world conditions. We test fasteners, adhesives, composite materials, metals, and plastics using industry-standard and custom methodologies. Our shear testing services are particularly valuable for applications where materials experience multi-directional forces in demanding environments. We specialize in both simple uniform materials and complex directional composites with the precision each requires.

- Fasteners and connectors

- Single and multi-layer adhesive bonds

- Composite laminates and structures

- Metal joints and welds

- Plastic components and assemblies

Methods and solutions offered

Methods and solutions offered

Address your most challenging materials performance questions with our versatile testing approaches that accommodate various material types and configurations. Our testing methods provide critical insights into how your materials behave under shear forces, helping you predict performance and prevent failures. We adapt our approach to match your specific application requirements and environmental conditions.

Element provides multiple shear testing methods tailored for different material types and applications, including:

Adhesive Shear Testing

- Single Lap Shear Testing: Evaluates a single adhesive layer between two bonded pieces. The pieces—typically metals, but also plastics or composites—are pulled in opposite directions until the adhesive fails.

- Double Lap Shear Testing: Similar to single lap shear testing, but with two adhesive layers. The adhesive is applied to both the top and bottom of a sample, with bonded pieces affixed on either side. These pieces are then pulled apart until both adhesive layers fail.

Composite Shear Testing

- In-Plane Shear Testing (ASTM D3518): Used for layered composite materials, this test measures how the material responds within the plane of lamination. It often involves pulling a specimen in tension using a ±45-degree layup. In addition to shear strength, it provides data on shear strain and elasticity. As testing progresses past 5% shear strain, results may deviate from shear loading because of the change in specimen geometry.

- Short Beam Shear Testing (ASTM D2344): This method bends a material using a short beam to estimate its interlaminar shear strength. This test is relatively easy to perform, making it ideal for quality control, screening, or evaluating environmental degradation effects such as fluid exposure or thermal cycling.

- V-Notch Shear Testing (ASTM D5379): A "V"-notched specimen is used to measure shear strength and modulus in all possible directions. The v-notched specimen can also be used for both in-plane and interlaminar shear tests.

- Interlaminar Shear Strength Testing (ASTM D2344, ASTM D3846, ISO 14130): Measures the shear strength between laminated layers by applying a load that causes the layers to slip past one another. This test evaluates the bonding quality of the resin or resin-fiber interface and is commonly used for quality control, screening, or assessing environmental effects like fluid exposure or thermal cycling.

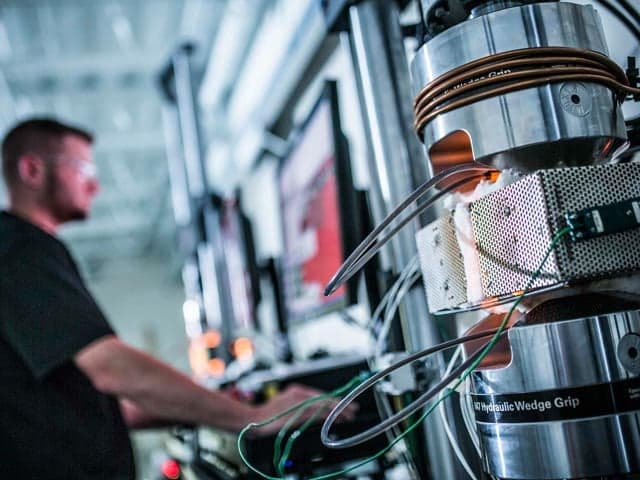

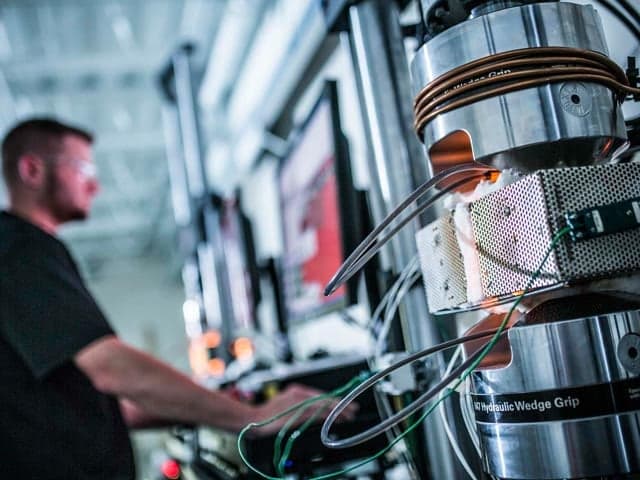

Cutting-edge equipment we use

Cutting-edge equipment we use

Our laboratories are equipped with advanced testing instruments designed to deliver precise, reliable results that you can trust for critical decision-making. Our fixtures ensure proper alignment and loading, critical for accurate shear data across all material types. For composite testing, we utilize specialized equipment for proper specimen preparation and fixture alignment, ensuring the highest quality results for your most demanding applications and complex material structures.

Which labs offer this service

Which labs offer this service

Our team operates from Materials Testing hubs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Standards we test to and materials we test

American Society for Testing and Materials: ASTM A263/264, ASTM A265, ASTM B565, ASTM B769, ASTM C1292, ASTM C1425, ASTM C273, ASTM C393, ASTM C394, ASTM D1002, ASTM D2295, ASTM D2344, ASTM D2557, ASTM D2919, ASTM D3080-04, ASTM D3163, ASTM D3164, ASTM D3165, ASTM D3166, ASTM D3518, ASTM D3528, ASTM D3846, ASTM D3914, ASTM D4255, ASTM D4475, ASTM D5379, ASTM D5448, ASTM D5656, ASTM D5868, ASTM D5961, ASTM D624, ASTM D7078, ASTM D7078, ASTM D7249, ASTM D7250, ASTM D732, ASTM D7616, ASTM D7617, ASTM D953, ASTM E143, ASTM F606/F606M

SAE International: SAE J2258, AMS-STD-401

International Organization of Standardization: ISO 14129, ISO 14130, ISO 9018

European Harmonized Standards: BS 1377, BS 2782, BS 4994, BS 4482, BS 4483, BS 5350 BS EN 2243, BS EN 2563 EN 2377, EN 2667 (PRen) EN ISO 14273, EN ISO 15630 NADCAP AC7122/1

Airbus: AITM 1-0002, AITM 1-0019, AITM 1-0030, AITM 1-0047

Aerospace Industries Association: NASM 1312-13, NASM-1312-20

American Welding Society: AWS B2.1, AWS B2.2, AWS B3.6M, AWS B4.0, AWS D17.2/17.2M, AWS D8.9M ANSI/AWS C3.2, ANSI/AWS D1.2, ANSI/AWS D1.3

American Society of Mechanical Engineers: ASME IX

German Institute for Standardization: DIN 50141, DIN 50162

The Suppliers of Advanced Composite Materials Association: SACMA SRM 3, SACMA SRM 3R & 8R, SACMA SRM 7, SACMA SRM 8

Other International Standards: IGC 04-26-346, NEN-6008, NPR-2053, SS 18, SS 32, SS 427, SS 456, SS 561

Adhesives

- Single lap adhesive joints

- Double lap adhesive bonds

- Metal-to-metal bonded assemblies

- Plastic-to-plastic adhesive joints

- Composite-to-metal bonded structures

Composites

- Polymer matrix composites

- Ceramic matrix composites

- Carbon fiber reinforced polymers

- Glass fiber reinforced polymers

- +/- 45 degree laminates

- Fabrics and braided composites

- V-notched composite specimens

Metal components

- Fasteners and connectors

- Welds and joined assemblies

- Clad materials

Construction materials

- Soil samples

- Building materials

- Structural components

Your Challenges, Our Solutions

Right test method for optimal results

Complex composites thoroughly characterized

Precision results for critical applications

Industry compliance made seamless

Why Choose Element

Comprehensive shear testing solutions

Specialized composite testing expertise

Variable temperature capabilities

Complex project experience

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Compression Testing

Element's compression testing services evaluate material strength, durability, and performance under load, helping you reduce failure risk, meet standards, and improve product development. Learn More.

Tensile Testing

Element's tensile testing provides accurate data on material strength, stiffness, and durability. Browse our range of tensile testing services including Open Hole tensile testing.