Fuels and Lubricants Testing

Safeguard your critical machinery and avoid unexpected failures with comprehensive Fuels and Lubricants Testing at Element. Detect quality issues, contamination, and early signs of wear before they impact your operations, reducing maintenance costs and extending equipment life while maintaining compliance with all industry standards.

What is Fuel and Lubricants Testing at Element?

Fuels and lubricants testing involves analyzing petroleum products to verify quality, monitor condition, and identify potential issues before they cause failures. Element focuses on evaluating the quality and performance of fuel and lubricant products to ensure they meet industry standards. We offer independent testing and technical investigations for both new products and in-service systems. Our services provide essential quality control and condition monitoring, helping to prevent failures and minimize unplanned downtime, ensuring smooth operations across diverse industries.

What Can Element Offer You For Fuels and Lubricants Testing?

Key Tests Offered

Key Tests Offered

We provide tailored testing solutions to address your specific operational challenges, whether you need regular quality control, condition monitoring, or specialized technical investigations. Our comprehensive approach includes expert guidance on sampling routines, detailed analysis of test results, and practical recommendations to optimize your maintenance strategy and prevent costly failures.

- Quality control of new and stored products - Comprehensive quality control tests for fuels (biofuels, jet fuel, gasoline, diesel, aviation gasoline) and lubricants (engine oils, transmission oils, hydraulic oils, etc.) based on international standards (ISO, ASTM, MIL).

- In-service condition monitoring through oil analysis - Regular monitoring to detect wear, contaminants, and lubricant degradation. We offer trend monitoring to predict potential issues before they cause failures.

- Technical investigations for failures and contamination – Our expert team undertakes investigations of abnormal wear, contamination or failure in mechanical systems, identifying root causes and providing guidance for correction

- Compatibility studies and additive effect analysis - Detailed tests on lubricants and fuels to assess compatibility between different formulations and the effects of additives on performance and degradation.

- Aircraft fuel systems testing for icing and contamination resistance - Specialized tests for fuel systems, ensuring they can withstand environmental stresses like icing and contamination, particularly in aviation fuel systems.

- Low Lubricity testing – Our team can test lubricants under extreme conditions to assess their ability to reduce friction and wear, using methods like the Ball on Cylinder Lubricity Evaluator (BOCLE).

- Hydrogen Fuel Testing - Testing of both gaseous and liquid hydrogen, including performance under varied temperatures (18K to 800K), to support the development of hydrogen-powered systems.

Products We Test

Products We Test

We test a comprehensive range of petroleum products used across multiple industries, from aviation and transportation to industrial manufacturing and power generation. Our capabilities include testing various fuels (jet fuel, diesel, gasoline, biofuel), oils (engine, hydraulic, turbine, transmission), and greases (lubricating, solid film, corrosion preventive), helping you maintain optimal performance and prevent costly system failures.

Fuel Products:

- Biofuel

- Jet Fuel

- Gasoline

- Diesel Fuel

- Aviation Gasoline

- Hydrogen Fuel

- Gaseous Hydrogen

- Liquid Hydrogen

Lubricant Products:

- Engine Oil

- Hydraulic Oil

- Instrument Oil

- Transmission Oil

- Aviation Turbine Oil

- Corrosion Preventive Oil

- Lubricating Grease

- Solid Film Lubricant

- Corrosion Preventive Grease

Our team are also able to test related fuel system components, covering:

- Hoses and Connectors

- Pumps

- Filters

- Filler Caps

- Injectors

- Tanks

- Hydraulic systems

- Gearboxes and transmissions

- Gas turbine engines (aviation, marine)

- Circulation systems(power generating turbines, industrial processes)

- Combustion engines

Which Labs Offer This Service

Which Labs Offer This Service

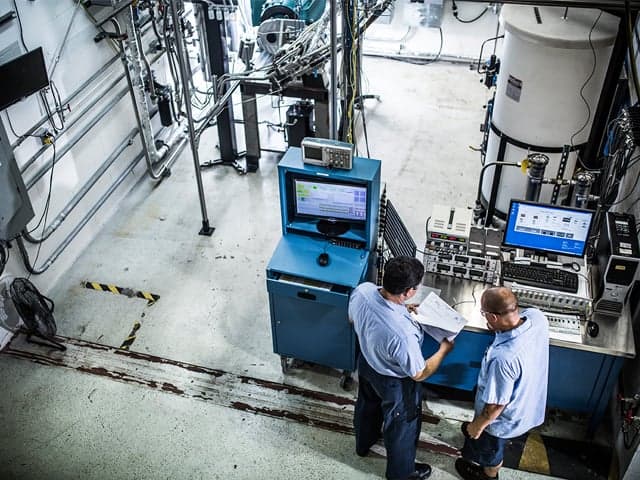

Our 8,500-strong team operates from Materials Testing hubs across the world - including our centre of excellence for fuels and lubricants testing in Sweden - providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Key Properties Tested for Quality

Key Properties Tested for Quality

- Appearance and Color

- Viscosity

- Acid/Base Number

- Additive Concentration

- Wear Metal Traces

- Contaminant Levels (e.g., oxidation, nitration, soot, glycol, water, fuel)

- Water Contamination

- Fuel Dilution

- Particle Count

- PQ Index

- Insoluble Contaminants

- Flash Point

- Air Release Characteristics

- Water Separability

- Foam Formation Properties

- Oxidation Stability (RPVOT)

- Antioxidant Levels (RULER)

- Varnish Potential (MPC)

- Rust Prevention Characteristics

Standards we test to and products we test

- ISO standards

- ASTM standards (including D6224 and D4378 for turbine oils)

- DIN standards

- MIL specifications

Fuel Products:

- Biofuel

- Jet Fuel

- Gasoline

- Diesel Fuel

- Aviation Gasoline

- Hydrogen Fuel

- Gaseous Hydrogen

- Liquid Hydrogen

Lubricant Products:

- Engine Oil

- Hydraulic Oil

- Instrument Oil

- Transmission Oil

- Aviation Turbine Oil

- Corrosion Preventive Oil

- Lubricating Grease

- Solid Film Lubricant

- Corrosion Preventive Grease

Our team are also able to test related fuel system components, covering:

- Hoses and Connectors

- Pumps

- Filters

- Filler Caps

- Injectors

- Tanks

- Hydraulic systems

- Gearboxes and transmissions

- Gas turbine engines (aviation, marine)

- Circulation systems (power generating turbines, industrial processes)

- Combustion engines

Your Challenges, Our Solutions

Inconsistent Fuel Quality

Lubricant Degradation and Contamination

Uncertainty Under Stress

Lack of Comprehensive Hydrogen Testing

Element Experts at your service

Why Choose Element

Independent petroleum analysis

Comprehensive testing capabilities

Technical investigation expertise

Full-cycle monitoring solutions

200+ test methods

40+methods accredited

24/7 online access

Frequently asked questions

What is the recommended frequency for in-service oil testing?

For most applications, we recommend testing 2-4 times per year. The ideal interval depends on your specific equipment, operating environment, and risk factors. Our experts can help establish the optimal testing schedule for your systems.

How does aircraft fuel systems testing work?

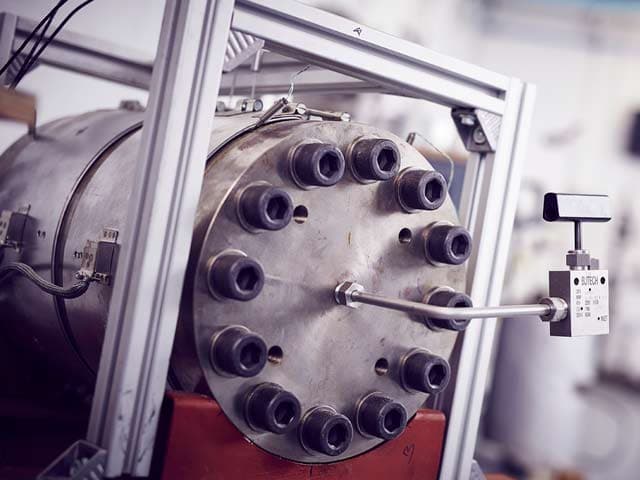

We condition high-pressure air, oil, or fuels to extreme temperatures while sustaining flow. For fuel icing testing, we cool fuel to -45°F while maintaining flow and pressure conditions to simulate real-world operations across all flight phases.

Does Element provide hydrogen fuel testing?

Yes, Element is currently the only UK facility offering both gaseous and liquid hydrogen testing. We conduct tests across a wide temperature range (18K to 800K) and provide precise, ATEX-compliant testing to support the development of hydrogen-powered systems, ensuring safety, performance, and regulatory compliance.

How does Element handle extreme testing environments?

Element's labs simulate real-world conditions, including extreme temperatures from -50°C to +150°C for automotive systems. Our facilities also support high-temperature and high-pressure testing, ensuring reliability under a variety of operational stressors.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aircraft Fuel System Testing

Element's comprehensive Aircraft Fuel System Testing services deliver validation at any scale. Our industry-leading experts work directly with you to design and implement tailored test programs precisely simulating real-world conditions.

Low Lubricity Aircraft Fuel Testing Services

Low lubricity aircraft fuel testing evaluates fluid performance under extreme conditions, identifying wear risks and optimizing maintenance strategies. Element provides precise, industry-standard testing for enhanced system longevity.

Hydrogen Testing

Element performs hydrogen testing, including hydrogen piping system and pipeline testing according to ASME B31.12, the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

Hydraulic Fluid Dynamics and Pneumatic Test Services

Access industry-leading hydraulic fluid dynamics testing and pneumatic test services with extreme pressure capabilities. Our single-source fluid susceptibility testing delivers reliable data and custom protocols.

Fuel Components Testing

Element provides comprehensive fuel components testing for automotive and military applications, helping manufacturers validate safety, durability, and compliance to industry standards, reducing risks and costly recalls.