Mastering Hydrogen's Motion: Simulating gust-induced sloshing in the fuel tank of a liquid hydrogen powered aircraft

This article details Element Digital Engineering's simulation of gust-induced sloshing in liquid hydrogen aircraft fuel tanks. Commissioned by the UK's Aerospace Technology Institute's FlyZero programme, Element developed a Computational Fluid Dynamics model to assess how aircraft motions impact cryogenic fuel behavior, aiding in the design of safer hydrogen-powered aircraft.

Background

The UK’s Aerospace Technology Institute (ATI) sets technology development objectives and funds research in the UK aerospace industry. Its FlyZero programme was a concerted effort across the sector to develop technology solutions to the problems of hydrogen powered aircraft. Element Digital Engineering was commissioned to investigate the problems associated with the thermo- and fluid dynamics of the liquid hydrogen fuel whilst the aircraft is on ground and in flight.

The challenge

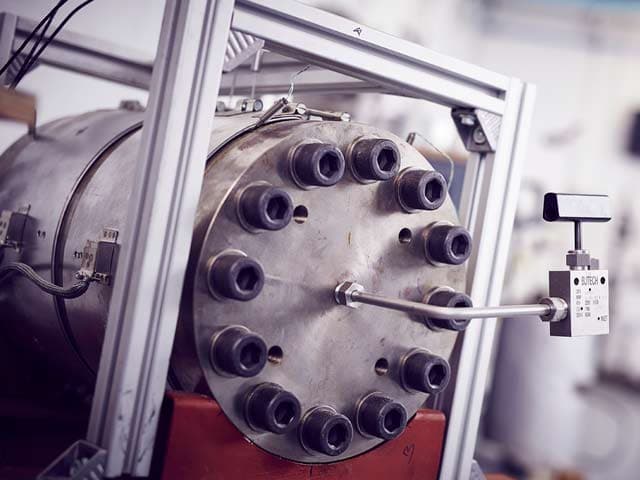

Liquid hydrogen fuel must be kept at an extremely low temperature, so the normal design solution of using the wings as fuel tanks is not adequate for hydrogen-powered aircraft. Instead, hydrogen must be stored in dedicated pressure vessels located inside the fuselage. Because of this, as the tank empties the fluid is free to slosh in response to aircraft motions. This is a known problem in conventional aircraft too, where the motion of the liquid can impose forces on the structure and alter the centre of gravity of the aircraft, but for liquid hydrogen fuel there is another, more serious problem.

As with any cryogenic fuel, the liquid component is constantly boiling off in response to the thermodynamic equilibrium in the tank. This boil-off is a problem, as it gradually raises the tank pressure, and is a function of the amount of exposed free surface of liquid. Sloshing increases the free surface area and accelerates the boil-off, posing a potential hazard.

The solution

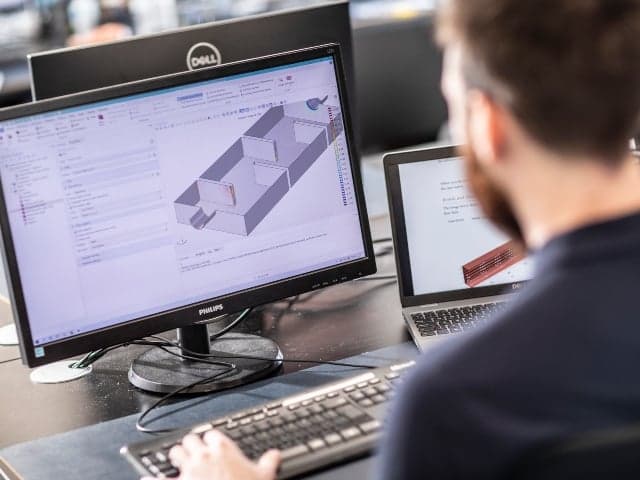

Element developed a Computational Fluid Dynamics (CFD) model of the fuel tank to simulate how the liquid hydrogen would respond to aircraft motions. CFD is a numerically-intensive mathematical tool used to solve the laws of conservation applicable to fluid flow problems. Recent developments in both numerical algorithms and computational power has allowed us to solve ever-more complex problems with CFD, including the modelling of heat transfer through the structure of the tank and the free surface between the liquid and gas inside the tank. The most challenging part was developing and validating against test a model for the equation of state that governs the boiling of the hydrogen.

We could then apply the aircraft motion data as a time-dependent series at the centre of gravity. The model responds by continuously predicting the motion of the liquid and gas, and the mass of gas that changes from liquid to gas state.

The result

The modelling demonstrated that certain extreme manoeuvres left the liquid hydrogen in a dispersed state throughout the tank, considerably increasing the surface area and accelerating the boil-off rate. Despite this, our work has demonstrated that the pressurisation of the tank was more-likely to be affected by other factors and not by the boil-off rate. The findings of this study have contributed to the conclusions of the “Cryogenic Hydrogen Fuel Systems and Storage Roadmap” published by ATI at the end of the FlyZero project. Element Digital Engineering are conducting research to assess means to dampen the liquid motion in the tank, while minimising the additional heat transfer caused by baffles.

Why Choose Element

Cryogenic Fuel Expertise

Advanced CFD Modelling

Validated Thermodynamic Simulations

Contributions to UK Aerospace R&D

Related Services

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

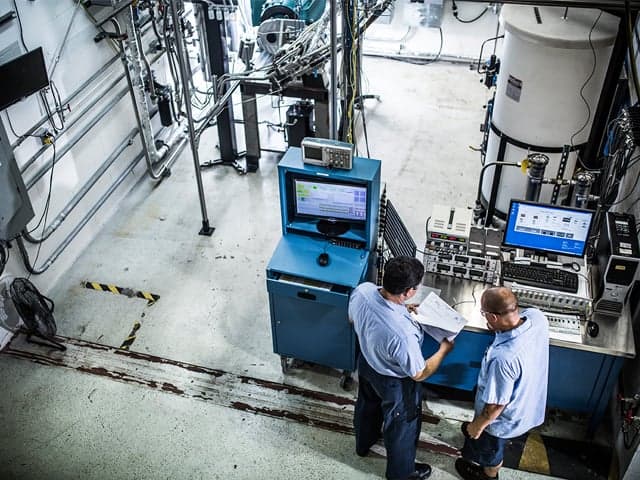

Aircraft Fuel System Testing

Element's comprehensive Aircraft Fuel System Testing services deliver validation at any scale. Our industry-leading experts work directly with you to design and implement tailored test programs precisely simulating real-world conditions.

Hydrogen Testing

Element performs hydrogen testing, including hydrogen piping system and pipeline testing according to ASME B31.12, the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.