Die Steel Qualification

Protect your valuable die investments and maximize production efficiency with expert die steel qualification testing. Our comprehensive metallurgical services help verify material quality, optimize heat treatment, and extend die life - providing hands-on technical guidance that streamlines your qualification process while reducing costly failures and production delays.

What is Die Steel Qualification at Element?

Steel dies are tools made of high-strength steel that are used in manufacturing processes such as stamping, molding, forging, and casting. Steel dies are essential for industries like automotive, aerospace, and metalworking, where precision and durability are crucial. Since dies undergo significant mechanical stress and wear, they need to be made from materials that can withstand high pressure, heat, and repeated use without losing their shape or integrity.

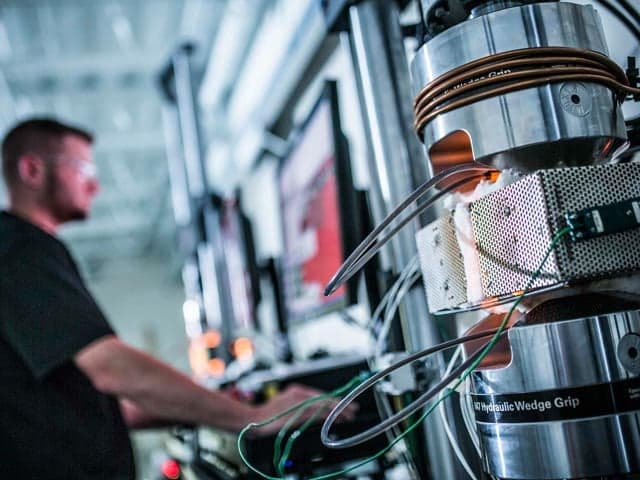

At Element, we provide comprehensive testing services including impact testing, heat treatment verification, and metallographic analysis to help ensure your dies meet industry specifications and perform reliably in production.

What Can Element Offer You For Die Steel Qualification?

Key tests offered

Key tests offered

We deliver comprehensive die steel testing including hardness verification after spheroidize annealing, inclusion cleanliness ratings, and micro-segregation analysis. Our full testing suite encompasses:

- Heat treatment evaluation and verification

- Hardness testing across multiple stages

- Charpy impact testing for toughness verification

- Microstructural analysis and rating

- Inclusion cleanliness assessment

- Banding and segregation evaluation

Materials and components we test

Materials and components we test

Our testing capabilities cover die steel materials, from plate and barstock to finished dies and heat-treated components. We evaluate test coupons attached to die inserts during heat treatment to verify proper material properties throughout production. This comprehensive approach allows you to protect your investment and maintain optimal production levels with reliable data-driven decisions.

Methods and solutions offered

Methods and solutions offered

Our testing approach combines multiple evaluation methods to identify potential issues before they impact production. This systematic approach helps prevent common causes of reduced die life, including poor material quality and improper heat treatment. Our comprehensive methodology includes:

- Verification that the material has sufficiently low hardness and acceptable microstructure after spheroidize annealing

- Rating its inclusion cleanliness

- Rating its degree of micro-segregation and banding

- Conducting heat treatments, hardness testing

- Charpy impact testing to verify it meets minimum impact energy requirements and can be heat treated properly.

Element qualifies commercially heat-treated dies by determining Charpy impact toughness, hardness and microstructural rating of test coupons. These test coupons are attached and heat-treated, along with the die inserts.

Quality control and verification

Quality control and verification

Our metallurgical experts perform detailed analyses using proven testing methods to rate inclusion cleanliness, evaluate microstructure, and verify material properties meet your specifications and industry standards. We support your production with comprehensive data that helps you achieve optimal performance from your dies and build more accurate productivity forecasts.

Standards we test to and materials we test

- North American Die Casting Association (NADCA) Specification #207-2003

- Ford Specification AMTD-DC2010

- GM's Worldwide Specification DC-9999-1

- Steel dies

- Die inserts

- Die steel plate

- Die steel barstock

- Heat-treated components

- Test coupons

Your Challenges, Our Solutions

Balancing quality verification and production demands

Extending die life

Reliable performance confirmation

Standards compliance complexity

Why Choose Element

Industry-leading expertise

Comprehensive testing capabilities

Quality you can trust

Global reach, local service

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

Charpy Impact Testing Services

Charpy impact testing provides a wealth of material data with a single impact strength test, ensuring safety and integrity of components and products. Learn More about our ISO 17025 accredited services.