Fatigue Testing Services

Prevent product failures and extend service life with comprehensive Fatigue Testing Services from Element. Our cyclic load testing identifies how your materials and components behave under repeated stress, helping you develop safer products, meet regulatory requirements, and understand performance limitations. Partner with our experts to predict and prevent fatigue failure before it impacts your customers.

What is Fatigue Testing at Element?

Fatigue testing characterizes material or component behaviour during cyclic loading. This testing measures the effects of cyclic forces on a product over time, simulating real-world conditions to predict fatigue failure, fatigue limits, and fatigue life

At Element, we provide comprehensive fatigue testing solutions using advanced test machines to analyze various cyclic loads under different speeds and environmental conditions, allowing us to create predictive patterns for material behavior. Our testing creates predictive patterns for material behavior, helping you understand vital properties such as fatigue failure mechanisms, fatigue limits, and expected fatigue life. Whether you're plotting stress against cycles to failure (S-N curves) or investigating specific failure scenarios, our expertise delivers the insights you need.

What Can Element Offer You For Fatigue Testing Services?

Key tests offered

Key tests offered

Our comprehensive fatigue testing program includes:

- Thermo mechanical fatigue (TMF) testing

- Axial fatigue testing

- Torsional fatigue testing

- Proof load testing

- Fatigue crack growth testing

- Resonance fatigue testing

- Rotating beam fatigue testing

- Multiple degrees of freedom fatigue testing

- Multi-channel/compound cyclic testing

- Strain Control

- Stress Control

- Displacement Control

- Frequency up to 100 Hz (rotating beam up to 150 Hz)

- Forces up to 250 kN

- Test temperatures from -320 to 2400 F

- Thermo Mechanical Fatigue Testing

- Custom and special project setups are available

Materials and components we test

Materials and components we test

We test metals, alloys, polymers, and composites across various industries. Our facilities accommodate everything from critical aerospace components to medical devices, industrial parts, consumer products, and pipeline welds. Our specialized capabilities include testing coatings and metallic surface treatments using rotating beam fatigue methods to assess their impact on fatigue performance. We work with materials from the smallest compressor airfoils up to full-size fan blades, providing tailored testing protocols for your specific applications.

- Metals and alloys: Steel, aluminum, titanium, and nickel-based superalloys

- Composites and polymers: Fiber-reinforced composites, polymer materials, composite laminates

- Medical devices and industrial components: Aerospace parts, compressor airfoils, fan blades

- Pipeline girth welds: Fatigue testing for pipeline materials and critical industrial applications

Methods and solutions offered

Methods and solutions offered

Our fatigue testing services utilize a variety of control methods, including strain control, stress control, and displacement control, to simulate real-world conditions and accurately assess material behavior. We also apply sinusoidal waveforms, constant amplitude loading, and high-frequency testing (up to 150 Hz) for rotating beam tests, ensuring precision and reliability in every test.

- Strain control, stress control, displacement control

- Sinusoidal waveforms and constant amplitude applications

- High-frequency testing (up to 150 Hz for rotating beam)

- Extreme temperature testing from -320°F to 2400°F

- Forces up to 250kN

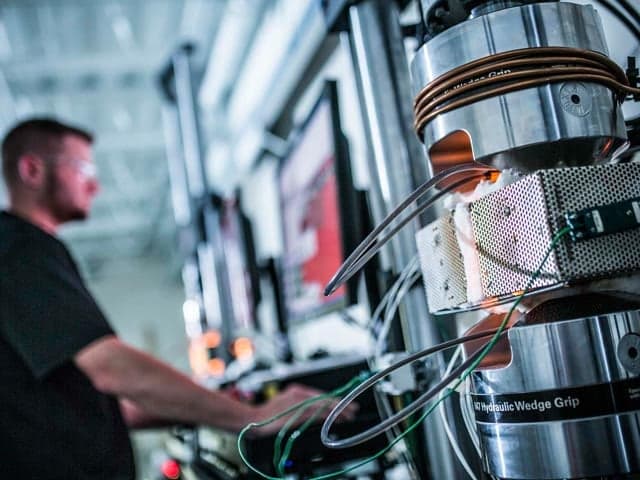

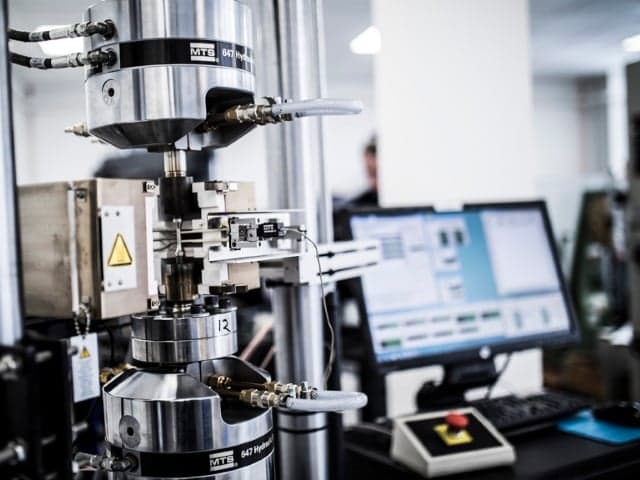

Cutting-edge equipment we use

Cutting-edge equipment we use

Our laboratories are equipped with state-of-the-art fatigue testing machines capable of handling a wide range of applications. We operate high-capacity test frames with multiple (9) product test chambers and specialized rotating beam machines, generating higher frequencies than traditional methods. Our equipment supports forces up to 250 kN and temperatures ranging from -320°F to 2400°F, ensuring the most accurate results in the most demanding conditions.

- Multi-channel testing capabilities for complex loading scenarios

- Custom and special project setups for unique applications

Comprehensive sample preparation and analysis

Comprehensive sample preparation and analysis

Beyond just testing, we provide end-to-end support from initial consultation through final analysis. Our experts assist in all stages of the process, from machining and polishing samples to interpreting test results. For rotating beam fatigue testing, specimens are carefully ground and polished to ensure the most accurate results. When failures occur, our detailed failure analysis identifies root causes and recommends preventive measures. This comprehensive approach ensures you receive not just data, but actionable insights to improve your products and processes.

Element Experts at your Service

Standards we test to and materials we test

Aerospace Industries Association/National Aerospace Standards

- NAS 1069, NASM 1312-11, NASM 1312-21

ASTM International

- ASTM C1360, ASTM C1361, ASTM D7774, ASTM D671, ASTM D3479, ASTM D4482, ASTM D6873, ASTM D6926, ASTM E206, ASTM E2368, ASTM E399, ASTM E466, ASTM E488, ASTM E606, ASTM E647, ASTM E1190, ASTM E1290, ASTM F1160, ASTM F1717, ASTM F1800, ASTM F2345, ASTM F2706

British Standards Institute

- BS 3518, Part 2 & 3, BS EN 1992-1-1

General Motors North America

- GMN7152, GMW16704, GMW16705

International Organization for Standardization

- ISO 1143, ISO 12107, ISO 3800, ISO 6157-3

Japanese Industrial Standard

- JIS B1051

Military/Department of Defense Standards

- DOD-STD-1312-111, MIL-STD-1312-11

National Aerospace Standards/Aerospace Industries Association

- NASM 1312-11, NASM 1312-21, NAS 1069

SAE International

- SAE J 123

We also test to a number of customer standards, including GE, Honeywell, SAFRAN, Pratt & Whitney, and MTU.

Metals and alloys

- Steel and steel alloys

- Aluminum and aluminum alloys

- Titanium and titanium alloys

- Nickel-based superalloys

Composites and polymers

- Fiber-reinforced composites

- Polymer materials

- Composite laminates

- Impact-damaged laminates

Components

- Pipeline girth welds

- Steel Catenary Risers

- Medical devices

- Aerospace components (compressor airfoils and fan blades)

- Industrial components

- Coatings and metallic surface treatments

Your Challenges, Our Solutions

Verifying product reliability

Achieving regulatory compliance

Confirming environmental performance across conditions

Unique products, requiring a bespoke approach

Why Choose Element

Fatigue testing leadership

Comprehensive testing capabilities

Industry-specific expertise

Solution-oriented approach

But don't just take our word for it

See what others want to say about partnering with Element

FAQs

What is rotating beam fatigue testing?

Rotating beam fatigue testing is a mechanical test method that evaluates fatigue properties by subjecting a beam specimen to cyclic loading under rotation. This induces repeated bending that causes failure over time. The test generates higher frequencies than traditional HCF methods and provides critical data about coatings and metallic surface treatments. Element performs these tests to ISO 1143, ASTM F1160 standards, or using bespoke methods to meet your specific requirements.

What is Thermo Mechanical Fatigue testing?

Our experts use this test to evaluate the combined effects of temperature and strain cycling on a material. Thermo mechanical fatigue testing is an important part of the material qualification for aerospace, oil and gas, transportation, and more. TMF is particularly useful if your materials and equipment experience a range of thermal environments during usages, such as turbine parts and engine components.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Engine Airfoil High Cycle Fatigue Testing (HCF)

Ensure the structural integrity of aerospace engine airfoils with Element's high cycle fatigue testing. Comprehensive solutions, expert analysis & advanced equipment. Find out more.

Weld Fatigue Testing of Steel Catenary Risers

Element's full-scale pipeline fatigue testing facility uses state-of-the-art mobile testing containers to perform laboratory or on-site weld fatigue testing of steel catenary risers.

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

Stress Rupture and Creep Testing

Element provides stress rupture and creep testing to evaluate material durability under prolonged stress and temperature. Our expert analysis supports manufacturers in preventing failures and ensuring long-term product performance.

Low Cycle Fatigue (LCF) Testing

Element offers ASTM E606 low cycle fatigue testing, simulating high-stress environments to predict material performance and deliver precise, reliable data for informed decision-making.

High Cycle Fatigue (HCF) Testing

Element offers advanced high cycle fatigue testing to meet ASTM E466 standards, preventing material failures and improving product reliability under real-world conditions. Trusted expertise for robust performance.