Mechanical and Physical Testing of Coatings

Coatings are subjected to extreme physical and mechanical stresses. At Element, we offer ISO 17025-certified testing programs designed to meet the specific needs of your industry and regulatory requirements. Our global laboratories provide actionable data that helps you verify coating durability, optimize performance, and prevent failures, ensuring reliability and compliance throughout the development and deployment of your product.

What Is Mechanical and Physical Testing of Coatings at Element?

Mechanical and physical testing evaluates coating resistance to mechanical stress, environmental wear, and deformation under real-world and accelerated conditions. At Element, we assess properties including adhesion strength, impact resistance, hardness, flexibility, and abrasion using standardized, ISO 17025-accredited methods. Our specialized equipment and expertise help you understand coating performance and prevent failures before deployment.

What Can Element Offer You For Mechanical and Physical Testing of Coatings?

Key tests offered

Key tests offered

Our testing portfolio evaluates all critical mechanical and physical properties, including:

- Water vapor permeability (moisture ingress)

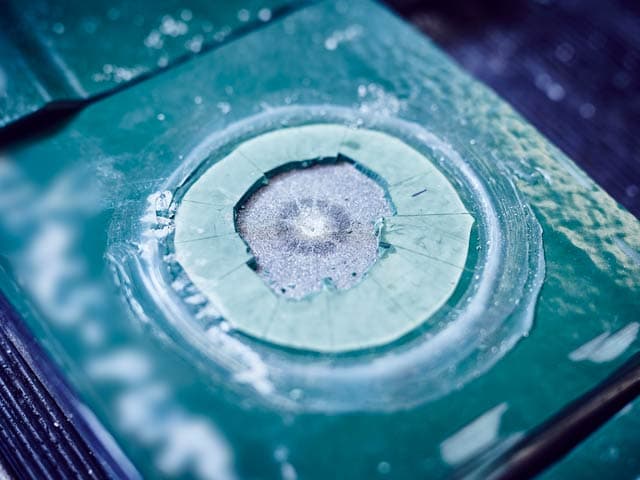

- Impact resistance (ASTM D2794, ISO 6272)

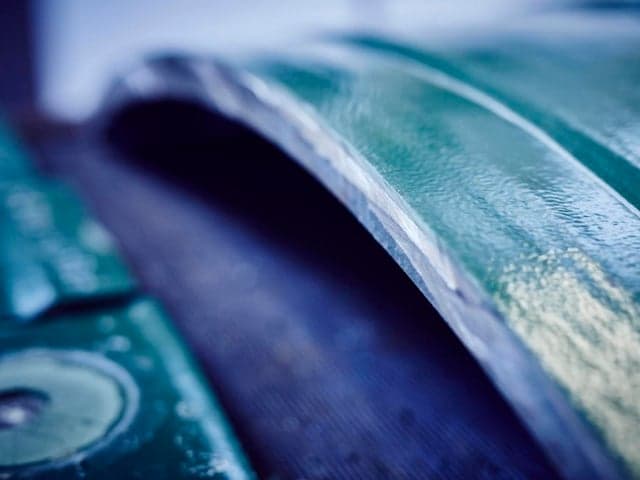

- Flexibility and deformation (ASTM D522, ISO 1519)

- Penetration and indentation (ISO 21809-1)

- Surface hardness (ASTM D3363, ISO 15184)

Methods and solutions offered

Methods and solutions offered

We implement customized test programs tailored to your specific requirements and regulatory landscape. Our methodologies help you achieve compliance while optimizing coating safety, reliability, and service life. We provide detailed analysis to help you understand coating performance under various conditions, allowing you to make informed decisions about coating selection and application for your specific needs.

- Bespoke test programs tailored to specific requirements

- Comprehensive coating performance evaluation

- Detailed analysis for informed decision-making

- Root cause failure analysis, identifying mechanical or material weaknesses in your coating systems; preventing repeat issues.

- Testing according to industry-specific requirements

Materials we test

Materials we test

We test a comprehensive range of industrial coatings designed for challenging environments. Our expertise extends to protective coatings for oil and gas applications, including pipeline coatings, Fusion Bonded Epoxy (FBE) systems, and corrosion-resistant coatings. Whether you need to verify coating performance on steel pipes or assess coating durability for harsh environments, our testing capabilities deliver the data you need.

- Protective industrial coatings for various applications

- Oil and gas pipeline coating systems

- Fusion Bonded Epoxy (FBE) coated steel materials

- Corrosion-resistant coating formulations

- High-performance coatings for specialized applications

Cutting-edge equipment we use

Cutting-edge equipment we use

Our ISO 17025 certified global coatings laboratories are equipped with versatile, state-of-the-art testing equipment to deliver precise, reliable results. Our specialized instruments conduct comprehensive evaluations including Taber abrasion testing, impact resistance assessment, flexibility measurement, adhesion strength testing, and precise dry film thickness measurement to provide you with accurate data about your coating's performance.

- Advanced Taber abrasion testing equipment

- Specialized impact resistance testing apparatus

- Precision flexibility and bend testing instruments

- Calibrated adhesion strength testing devices

- High-accuracy dry film thickness measurement tools

Which labs offer this service

Which labs offer this service

Our team operates from Energy hubs across the world, providing global access to our expert capabilities. Find your nearest Energy hub on our Locations Page.

Standards we test to and materials we test

- Taber Abrasion– ASTM D4060

- Volume Solids – ISO 3223

- Impact – ASTM D2794, ISO 6272

- Flexibility – ASTM B489, ASTM D522, ASTM D790, CSA Z245.20, ISO 1519, ISO 178, ISO 6860

- Indentation – ISO 21809-1 and 3

- Adhesion testing – ASTM D3359, ASTM D4541, ASTM D6677, ISO 2409, ISO 4624

- Dry Film Thickness (DFT) – ASTM D7091, ISO 19840

- Hardness testing – ASTM D2240, ASTM D3363, ISO 15184, ISO 7619

Industrial coatings

- Protective coatings for various environments

- Corrosion-resistant coating systems

- High-performance industrial coatings

Oil and gas specific coatings

- Pipeline coating systems

- Fusion Bonded Epoxy (FBE) coatings

- Steel pipe protective coatings

Your Challenges, Our Solutions

Harsh Conditions Threaten Coating Performance

Struggle Navigating Complex Standards

Coating Failures Risking Downtime

Inconsistent Data Undermines Quality Assurance

Why Choose Element

Global laboratory network

Comprehensive testing capabilities

Industry-specific expertise

Customized testing programs

Frequently asked questions

What is the importance of mechanical and physical testing of coatings?

Mechanical and physical testing helps manufacturers and engineers understand how coatings will perform throughout their product life. These tests evaluate crucial properties like adhesion, hardness, flexibility, and abrasion resistance, helping prevent failures, ensure compliance, and optimize coating performance in real-world applications.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Coating & Particulate Testing

Element provides coating integrity and particulate testing for intravascular devices, helping manufacturers meet safety standards, improve device performance, and comply with regulatory guidelines.

Testing of Porous Structure and Porous Coatings for Medical Devices

Element provides porous structure testing for medical devices, evaluating mechanical and metallurgical properties to support regulatory compliance, product development, and supplier validation.

Surface and Coatings Testing Services

Optimize durability & compliance with Element’s Surface & Coatings Testing Services. Fast, accredited testing with expert insights to enhance product performance

Paint and Coating Testing Services

Get reliable paint & coating testing services to verify durability, ensure compliance, and reduce defects. Fast, integrated solutions tailored to your industry.

Water Immersion Testing

Element's water immersion testing evaluates coating performance in submerged conditions, identifying degradation risks like blistering and adhesion loss. Get reliable data to meet industry standards and enhance material longevity.

Coating and Paint Adhesion Testing

Adhesion testing services for paints and coatings to evaluate performance, meet ASTM standards, and address coating failures with expert analysis and actionable insights.