Aircraft Icing and Rain Test Methods

We provide end-to-end aircraft icing testing and rain test methods to help you bring products to market quickly and confidently. Our hands-on technical guidance ensures every component meets regulatory standards while preventing costly failures. Rely on our global network of labs and advanced environmental simulations to streamline your entire testing process, from start to finish.

What is Aircraft Icing and Rain Testing at Element?

Rain and icing tests evaluate how aircraft products perform under extreme weather conditions. At Element, we provide comprehensive environmental simulation services that assess physical deterioration, water penetration, and ice formation on aircraft components. We have been making certain for nearly 190 years, delivering reliable test data so you can confidently meet strict aerospace and military standards.

What can Element offer you for Aircraft Icing & Rain Testing?

Components & Materials We Test

Components & Materials We Test

Element test a range of aircraft parts under real-world ice and rain conditions - including rain test methods and all three RTCA DO-160 equipment categories for icing testing. Our scope includes:

- External aircraft equipment

- Electrical equipment enclosures

- Component coatings and sealants

- Structural aircraft components

- Road vehicle electrical equipment

Key Tests Offered

Key Tests Offered

Rain tests we offer include:

- Blowing rain tests

We use specified wind velocity and rainfall rates to determine how a product will endure its outdoor environment. - Drip tests

We measure water penetration or pooling caused by repeated droplets falling at a uniform rate.

Water ingress protection tests include:

We test the effectiveness of seals on the enclosures of electrical equipment (including IEC 60529, NEMA 250 & UL 50E, DIN 40050-9).

- IP Testing (IEC 60529): IEC 60529 is an international standard designed to give products a determined International Protection Marking according to the IP Code rating. This standard tests the sealing effectiveness of enclosures of electrical equipment against the intrusion of solid particles and liquid.

- Electrical Enclosure Rating Testing (NEMA 250 & UL 50E): Specific to North America, NEMA 250 (National Electrical Manufacturers Association) ratings cover additional product features and tests such as functionality under construction requirements, electrical enclosures for hazardous areas and industrial applications against environmental hazards such as water, dust, oil or corrosive atmospheres.

- High Pressure Steam Jet Cleaning (DIN 40050-9): Covers degrees of protection of electrical equipment of road vehicles against foreign objects, water and access.

Aircraft icing tests:

Include 3 RTCA DO-160 Categories -

- Category A

For equipment located externally or in non–climate-controlled areas where aircraft icing and frost may occur due to condensation. - Category B

A 25-cycle test mimicking multiple ascents and descents, where water accumulation can damage moving parts and electronic systems. - Category C

Used for external areas exposed to standing water that can freeze, causing ice buildup that impedes normal operation.

Methods and Solutions Offered

Methods and Solutions Offered

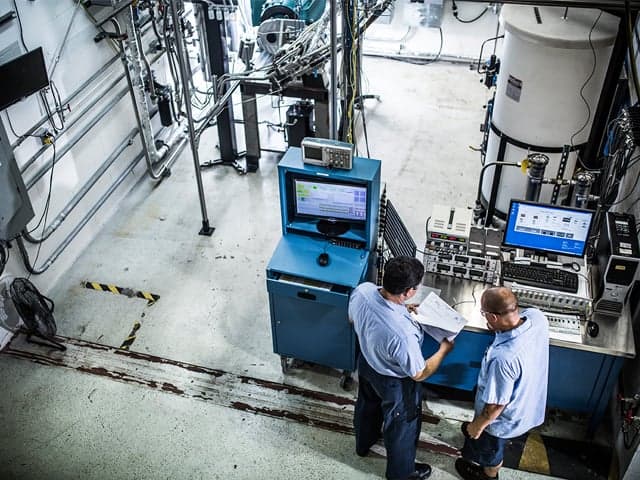

Our automated chambers combine altitude, humidity, and freezing temperatures for realistic testing across RTCA DO-160 categories.

We offer advanced solutions like Bird Strike Testing, Hail Impact Testing, Fuel System Testing, and more. Explore our full range of aerospace and environmental simulation services to address every aspect of product performance.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

- Automated environmental chambers for combined condition testing (altitude, temperature, humidity).

- High-pressure and blowing rain apparatus for replicating severe storm conditions.

We deliver certainty—high-quality data, test reports, and certificates you can rely on when making critical decisions about design and compliance.

Which Labs Offer This Service

Which Labs Offer This Service

Our team works in product qualification hubs across the world, so you can test locally or leverage our global network. Find your nearest lab on our Locations Page.

Standards we meet and the products we test

United States Military Standard

- MIL-STD 810, Method 506, Procedure I – Rain and Blowing Rain Test

- MIL-STD 810, Method 506, Procedure III – Drip Test

Radio Technical Commission for Aeronautics

- RTCA DO-160

International Electrotechnical Commission

- IEC 60529 – Ingress Protection Test

National Electrical Manufacturers Association

- NEMA 250 – Ingress Protection Test

Underwriters Laboratories

- UL 50E – Enclosures for Electrical Equipment

German Institute for Standardization

- DIN 40050-9 – High-Pressure Steam Jet Cleaning

Other Specifications

- NMX-J-307/1-ANCE – Rain Test for lighting fixtures

- External aircraft equipment

- Electrical equipment enclosures

- Component coatings and sealants

- Structural aircraft components

- Road vehicle electrical equipment

Your Challenges, Our Solutions

Product Safety and Reliability

Complex Regulatory Compliance

Water Damage Prevention

Multi-Condition Performance

Why Choose Element

Complete Testing Coverage

Advanced Testing Capabilities

Expert-Guided Solutions

Global Network of Labs

Frequently asked questions

What kind of damage can rain and water exposure cause to aircraft components?

Water exposure can degrade coatings, sealants, and structural integrity, affecting overall performance. This is particularly critical for products in outdoor and high-condensation environments.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aircraft Fuel System Testing

Element's comprehensive Aircraft Fuel System Testing services deliver validation at any scale. Our industry-leading experts work directly with you to design and implement tailored test programs precisely simulating real-world conditions.

Aerospace RTCA DO-160 Testing

Element RTCA DO-160 Testing: Single-Source DO-160 Testing Performed In State-Of-The-Art Labs. Schedule Your Test Today.

MIL-STD-810 Testing Services

Element's MIL-STD-810 testing services validate military and defense products under extreme conditions, delivering reliable, accredited results for compliance and performance qualification.

Climatic & Environmental Chamber Testing Services

Test your products' durability with environmental chambers at Element. Accurately simulate real-world conditions to meet industry standards and ensure performance.

IP Ingress Protection Testing Services

Element's IP Ingress Protection testing ensures compliance, durability, and reliability. Fast, expert testing for aerospace, defense, automotive, and electronics. Learn More.