Ozone Testing Services

Ensure your product's long-term performance and validate supplier quality with expert-led ozone testing services. Serving industries like automotive, aerospace, and defense, we help you guarantee the ozone resistance of rubber and elastomer components to meet rigorous durability standards. Get certainty about your materials' resistance to ozone degradation.

What is ozone testing at Element?

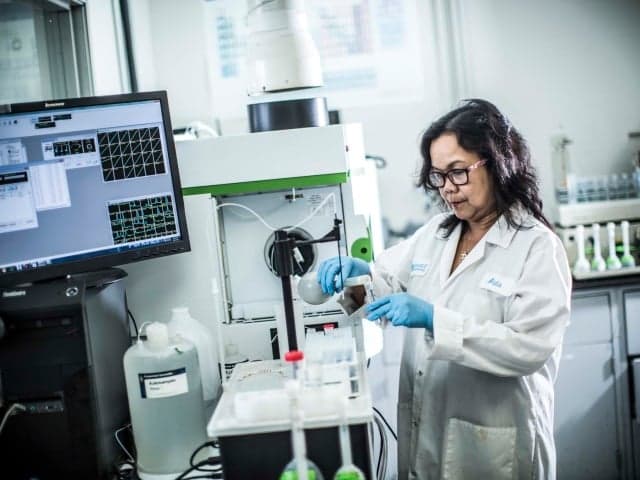

Ozone testing determines a rubber or elastomer’s resistance to ozone degradation by exposing samples in a controlled chamber to a specified ozone concentration and duration, simulating real-world environmental conditions. At Element, we conduct specialized testing that exposes rubber and elastomer samples to precise ozone concentrations for specified durations, helping you identify potential surface cracking and material failures before they impact your products.

What can Element offer you for ozone testing?

Key Tests Offered

Key Tests Offered

Our ozone deterioration testing services assess materials for ozone-induced surface cracking and structural failure, including complete breaks in severe cases. These tests evaluate materials' integrity and long-term performance, aiding in informed decisions on material selection and supplier quality.

Testing follows recognized international standards: ASTM D518-99 (surface cracking), ASTM D1149 (ozone-controlled exposure), and ASTM D1171 (outdoor or chamber testing with triangular specimens).

Components And Products We Test

Components And Products We Test

We test a comprehensive range of rubber and elastomer components critical to automotive, aerospace, and defence applications. Our testing capabilities cover everything from vehicle hoses and tires to specialized military and aerospace components, ensuring your materials meet industry-specific durability requirements.

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from Materials Testing hubs across the world, providing comprehensive ozone testing services to customers around the world. Find your nearest Materials Testing hub on our Locations Page.

Standards we test to and materials we test

Our Engaged Experts conduct Ozone deterioration testing in compliance with the primary standards established by international organizations, including:

- ASTM D518-99: Standard Test Method For Rubber Deterioration-Surface Cracking

- ASTM D1149: Standard Test Methods For Rubber Deterioration - Cracking In An Ozone Controlled Environment

- ASTM D1171: Standard Test Method For Rubber Deterioration-Surface Ozone Cracking Outdoors Or Chamber (Triangular Specimens)

We test a wide range of materials and components critical to industries like automotive, aerospace, and defense, including:

- Rubber

- Elastomers

- Polymers

- Silicones

- Vehicle components (hoses, tires, grommets, wheels)

- Other rubber components used in various industrial applications.

Your Challenges, Our Solutions

Long-term Performance Uncertainty

Supply Chain Quality Concerns

Regulatory Compliance Requirements

Material Degradation Risks

Why Choose Element

Multi-Industry Experience

Standards Compliance

Quality Assurance Focus

Global Expert Network

Frequently asked questions

Why is ozone testing particularly important for automotive suppliers?

Ozone testing is a routine requirement in the automotive and transportation industries. It's particularly effective for rubber components and helps suppliers validate their materials meet industry durability standards before entering the supply chain.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

Climatic & Environmental Chamber Testing Services

Test your products' durability with environmental chambers at Element. Accurately simulate real-world conditions to meet industry standards and ensure performance.