Medical Device Testing Services

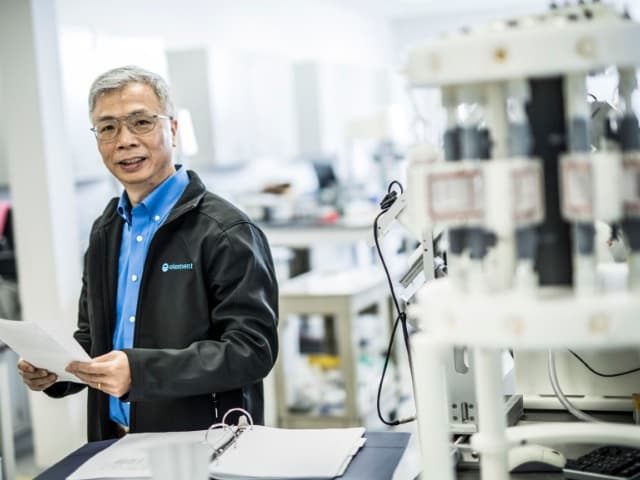

Bringing innovative medical devices to market involves significant risks. Element provides absolute medical device testing certainty with reliable, comprehensive results across all device classes. From small startups to established manufacturers, our single-source approach covers your entire product lifecycle - from prototype to regulatory approval - reducing complexity and costs while eliminating the complexity of managing multiple testing vendors and ensuring compliance.

Why Element are global leaders in medical device testing

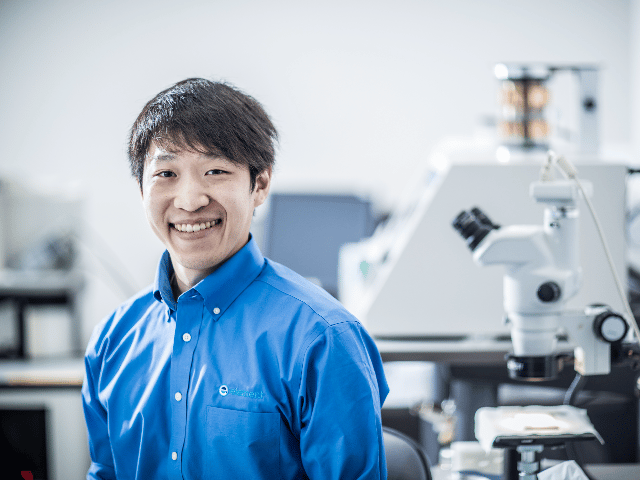

The medical device industry faces increasingly complex regulatory requirements and safety standards across global markets, with testing playing a critical role in bringing new innovations to patients. From implantable devices to diagnostic equipment, rigorous testing helps manufacturers navigate strict FDA and international regulations while validating product safety and effectiveness.

Medical device testing evaluates safety, reliability, and regulatory compliance through comprehensive assessment of how devices function, protect users, and perform over time. For medical device testing solutions that you can trust, our dedicated team of experts have years of experience in a wide range of testing services for Class, I, II and III medical devices to help you meet regulations and ensure that every aspect of your medical device product is properly tested.

We offer a full suite of medical device testing, including:

Element supports every stage of medical device testing - from test protocol development and prototype/feasibility trials to testing and consultation for:

Our turnkey invasive and non-invasive Physiological Monitoring Studies cover the entire product lifecycle, from R&D to validation for regulatory submission.

With Element as your medical device testing partner, you’ll enjoy the benefit of a single comprehensive supplier for your testing needs, from feasibility, R&D and prototype trials to product development, regulatory validation and production quality control. Our methodical validation processes ensure your devices meet performance requirements and quality standards consistently for confident manufacturing and regulatory submissions.

Services

EU Medical Device Regulation Testing

Accelerate your medical device certification with Element's comprehensive safety testing to the Medical Device Directive.

Wireless Medical Device Testing Services

Accelerate your wireless medical device’s journey to market with Element's comprehensive testing solutions. From remote patient-monitoring systems to IoT-enabled devices – Learn More.

Bone Plate, Bone Screw, and Fixation Device Testing

Our testing service verifies the mechanical integrity of bone plates, screws, and fixation devices through ASTM-standard fatigue, bending, and torsion evaluations, providing critical data for regulatory compliance and trauma reliability.

Cardiac & Endovascular Device Testing

Element offers comprehensive cardiac and endovascular device testing, providing fatigue and durability analysis to support regulatory compliance and product reliability for stents, heart valves, pacemaker leads, and more.

Chemical Compatibility Testing for Medical Devices, Materials, and Surfaces

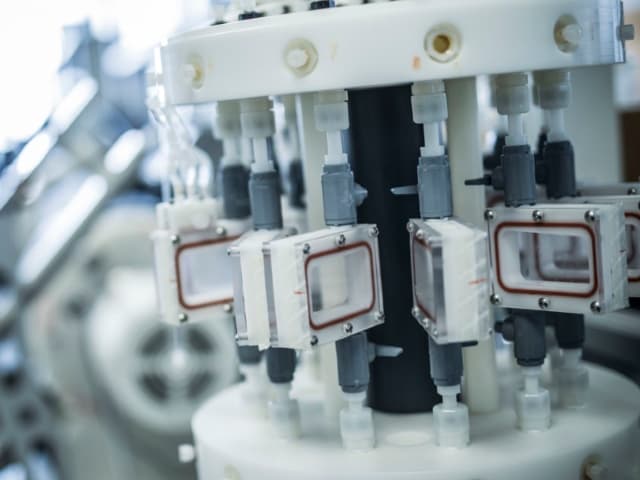

Our automated chemical compatibility testing verifies that medical devices withstand corrosive disinfectants, offering comprehensive, fast, and reliable evaluations that preserve product integrity and extend device longevity in harsh cleaning environments.

Cleanliness and Microbiological Testing

Element's Cleanliness and Microbiological Testing service validates cleaning processes, evaluates microbial loads, and performs bioburden, endotoxin, and cytotoxicity tests to reduce contamination risks and support device performance and patient safety.

Clinical Validation Testing

Element delivers comprehensive clinical validation testing for medical devices and wearables, managing study design, recruitment, testing, and data analysis. Our complete solutions help overcome regulatory challenges and accelerate product development.

Blood Pressure Monitor Clinical Validation Testing

Element provides comprehensive blood pressure monitor clinical validation testing—from protocol design and participant recruitment to data analysis—leveraging invasive and non-invasive methods to overcome regulatory challenges and deliver precise device performance.

Consumer Electronics Testing and Certification

Get expert consumer electronics testing to accelerate your market entry. Element's accredited EMC, safety & wireless compliance services facilitate smoother market entry.

Heart Rate Monitor Device Validation

Element provides clinical validation testing for heart rate monitors using human and simulator data, meeting regulatory standards while delivering accurate performance. Their expert guidance addresses key accuracy challenges.

Human Factors and Usability Testing

Element's human factors and usability testing simulates real-world device use to reveal user errors and optimize performance. The service supports FDA guidelines and enhances overall device safety and effectiveness.

Pulse Oximeter Validation Testing

Element's pulse oximeter clinical validation service provides comprehensive human testing that delivers real-world, high-quality data to support regulatory submissions and significantly optimize device performance across diverse clinical settings with precision.

Respiratory Rate Monitor Clinical Validation Testing

Element offers expert-led respiratory rate monitor clinical validation testing, covering protocol design, participant recruitment, and regulatory-ready reports for streamlined submissions.

Sleep Monitoring Device Validation

Element provides clinical validation testing for sleep monitoring devices, supporting regulatory submissions and optimising device safety through expert-led data analysis and participant studies.

Temperature Monitoring Device Clinical Validation Testing

Element offers expert clinical validation testing for temperature monitoring devices, supporting regulatory requirements and fast-tracking your product to market with comprehensive study management.

Coating & Particulate Testing

Element provides coating integrity and particulate testing for intravascular devices, helping manufacturers meet safety standards, improve device performance, and comply with regulatory guidelines.

Electrochemical Corrosion Testing

Element offers electrochemical corrosion testing to identify material risks, enhance durability, and support informed material selection across industries.

Foot, Ankle, and Shoulder Replacement Implant Testing

Element offers expert foot, ankle, and shoulder implant testing, covering fatigue, wear, and constraint analysis to support orthopedic device development and regulatory submissions.

Heart Valve Device Testing

Element offers heart valve device testing, simulating real-life conditions to evaluate durability, fatigue, and performance, helping manufacturers develop reliable cardiovascular implants.

IEC 60601 Medical Device Safety Testing services

Element provides testing and certification to IEC 60601 to assess the safety and essential performance of electrical medical devices.

ISO 10555 Catheter Testing services

We offer comprehensive testing services for catheters and balloons under ISO 10555 standards for testing intravascular sterile use catheters.

ISO 11070 Guidewire Testing

Element offers ISO 11070 guidewire testing, evaluating cardiovascular devices for performance, durability, and safety through simulated use, tensile strength, torque, and flexibility tests.

ISO 14801: Dental Implant Testing

Element provides ISO 14801 dental implant fatigue testing to support regulatory approval. Our experts deliver precise data on implant durability, lifecycle, and performance for safe market entry.

Hip Joint Prosthesis Testing

Element provides ISO 7206-compliant hip joint prosthesis testing, assessing endurance, fatigue, and compression to support safe, high-performing medical devices worldwide.

Knee Implant Testing

Element offers expert knee implant testing, including fatigue, wear, and constraint analysis, to support device design, feasibility studies, and regulatory compliance.

Battery Safety Testing for Medical Devices

Battery safety testing for medical devices, assessing performance, reliability, and compliance with international standards to support safe use in healthcare settings.

Medical Device EMC Testing

Element provides EMC testing and certification for Class I-III medical devices, helping manufacturers meet global regulatory standards and accelerate market entry with expert guidance and accredited laboratories.

Medical Device Regulatory Services

Element offers expert medical device regulatory consulting, guiding you through design, risk analysis, and FDA submissions for efficient product approval.

Medical Device Safety Testing

Accelerate your medical device safety testing with Element's end-to-end services. From design consultation to global certification, we navigate complex regulations so you can launch faster.

Nickel Ion Release Testing

Element evaluates nickel icon release from nitinol and other nickel-rich medical devices to help medical device manufacturers characterize nickel ion leaching.

Occluder & Closure Device Testing

Element offers advanced occluder device testing, evaluating durability and fatigue to support safe, long-term cardiovascular performance through expert-led, specialized testing protocols.

Orthopedic Device Testing Services

Accelerate orthopedic device development with Element's comprehensive testing services. From hip to spinal implants, we ensure regulatory compliance while reducing time-to-market. Expert support at every stage—prototype to commercialization.

Pacemaker Lead Testing

Pacemaker lead testing evaluates safety, performance, and compliance with industry standards. We simulate real-world conditions to help manufacturers bring safe, reliable cardiovascular devices to market.

Pin on Disk Wear Testing

Pin on disk wear testing evaluates material wear performance under controlled conditions. Ideal for regulatory requirements and material comparison, Element's advanced methods and expertise deliver reliable insights.

Testing of Porous Structure and Porous Coatings for Medical Devices

Element provides porous structure testing for medical devices, evaluating mechanical and metallurgical properties to support regulatory compliance, product development, and supplier validation.

Rated Burst Pressure & Leak Testing

Element provides rated burst pressure and leak testing for medical devices, ensuring safety and compliance with ISO standards. Services include fatigue, flow rate, and pressure-diameter analysis for balloons, catheters, and grafts.

Reusable Medical Device Life Cycle Validation

Comprehensive life cycle validation for reusable medical devices. Supporting compliance, patient safety, and regulatory approval through expert testing and risk mitigation.

Reusable Medical Device Reprocessing and Testing (GLP Compliant) services

Element's expert validation services for reusable medical devices ensure your equipment is GLP compliant, protecting your staff and your patients.

Silicone Mock Vessels

Our cardiovascular device testing experts have extensive experience designing custom mock vessels for pulsatile fatigue testing and other test methods for devices such as stents, occluders, and heart valves.

Spinal Implants Testing Services

Element's trusted medical device testing covers fusion and non-fusion spinal devices, as well as predicate components, to ensure their durability and lifespan in use.

Stent & Stent Graft Testing Services

Element provides expert stent testing services to validate cardiovascular device compliance, durability, and performance. Our comprehensive testing meets regulatory standards, supporting safe and effective device

Prefilled Syringe Testing

Element provides expert prefilled syringe testing, assessing functionality, integrity, and compliance with ISO standards. Our services help medical device manufacturers meet regulatory requirements with precision and confidence.

Wear Testing of Medical Devices

Element can handle every aspect of your medical device wear test program, no matter how long you want the tests to run for or how many repeats you need.

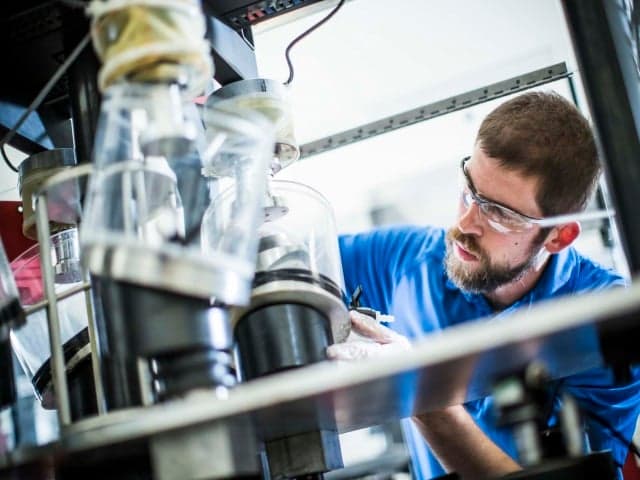

Pharmaceutical Medical Device and Product Testing

With Element as your medical device testing partner, you’ll enjoy the benefit of a single comprehensive supplier across feasibility, R&D and prototype trials, through product development, regulatory validation and production quality control.

510(k) Testing & Consulting

Successful FDA 510(k) submissions are critical to your market success. Incomplete or inaccurate submissions can lead to failure and may delay your product launch. Our Engaged Experts are ready to assist.

Hand Sanitizer Efficacy Testing

Element offers complete hand sanitizer efficacy testing, including USP 611 GC-FID and GC-MS methods, to verify alcohol content, purity, and safety, helping products meet regulatory standards.

Medical Grade Polymer Testing

Comprehensive medical grade polymer testing to support device development, improvement, and compliance with regulatory standards. Tailored solutions address safety, quality, and performance needs in medical devices.

Polymeric Failure Analysis Services for Medical Devices

Element's experts provide failure analysis of polymer-based medical devices, which is critical to ensuring that process or material improvements can be made to prevent repeated failures.

- EU Medical Device Regulation Testing

- Wireless Medical Device Testing Services

- Bone Plate, Bone Screw, and Fixation Device Testing

- Cardiac & Endovascular Device Testing

- Chemical Compatibility Testing for Medical Devices, Materials, and Surfaces

- Cleanliness and Microbiological Testing

- Clinical Validation Testing

- Blood Pressure Monitor Clinical Validation Testing

- Consumer Electronics Testing and Certification

- Heart Rate Monitor Device Validation

- Human Factors and Usability Testing

- Pulse Oximeter Validation Testing

- Respiratory Rate Monitor Clinical Validation Testing

- Sleep Monitoring Device Validation

- Temperature Monitoring Device Clinical Validation Testing

- Coating & Particulate Testing

- Electrochemical Corrosion Testing

- Foot, Ankle, and Shoulder Replacement Implant Testing

- Heart Valve Device Testing

- IEC 60601 Medical Device Safety Testing services

- ISO 10555 Catheter Testing services

- ISO 11070 Guidewire Testing

- ISO 14801: Dental Implant Testing

- Hip Joint Prosthesis Testing

- Knee Implant Testing

- Battery Safety Testing for Medical Devices

- Medical Device EMC Testing

- Medical Device Regulatory Services

- Medical Device Safety Testing

- Nickel Ion Release Testing

- Occluder & Closure Device Testing

- Orthopedic Device Testing Services

- Pacemaker Lead Testing

- Pin on Disk Wear Testing

- Testing of Porous Structure and Porous Coatings for Medical Devices

- Rated Burst Pressure & Leak Testing

- Reusable Medical Device Life Cycle Validation

- Reusable Medical Device Reprocessing and Testing (GLP Compliant) services

- Silicone Mock Vessels

- Spinal Implants Testing Services

- Stent & Stent Graft Testing Services

- Prefilled Syringe Testing

- Wear Testing of Medical Devices

- Pharmaceutical Medical Device and Product Testing

- 510(k) Testing & Consulting

- Hand Sanitizer Efficacy Testing

- Medical Grade Polymer Testing

- Polymeric Failure Analysis Services for Medical Devices

Your Challenges, Our Solutions

High Market Entry Risk

Complex Regulatory Requirements

Multiple Testing Management

Standards we test to and components we test

- FDA Quality System Regulation (21 CFR Part 820)

- ISO 13485 - Medical devices Quality management systems

- ISO 14971 - Medical devices Application of risk management

- ISO 10993 - Biological evaluation of medical devices

- IEC 60601 - Medical electrical equipment safety

- EU Medical Device Regulation (MDR 2017/745)

- ASTM F2129 - Corrosion testing of implantable materials

- ISO 11607 - Packaging for terminally sterilized medical devices

- ANSI/AAMI/ISO 11135 - Sterilization validation

- Additional product-specific standards based on device classification and type

- Metals and alloys (stainless steel, titanium, nitinol, cobalt-chrome)

- Polymers (PEEK, UHMWPE, silicone, PVC, polypropylene)

- Ceramics and bioceramics

- Composite materials

- Bioabsorbable materials

- Coatings and surface treatments

- Adhesives and bonding agents

- Packaging materials

- Electronics components and batteries

- Textiles and non-woven materials

Why Choose Element