Elemental Impurities Testing and Analysis

Protect product quality and accelerate market approval with precise elemental impurities testing that exceeds regulatory requirements. Our advanced analytical methods detect trace elements down to parts per trillion, supported by expert guidance for USP <232>/<233> and ICH Q3D compliance. Experience seamless testing from raw materials through finished products.

What is Elemental Impurities Testing and Analysis at Element?

Elemental impurities testing identifies and quantifies trace metal contaminants that can be introduced during pharmaceutical and biopharmaceutical manufacturing. At Element, we deliver highly accurate, element-specific protocols using advanced analytical methods to detect impurities in raw materials, APIs, drug products, and packaging materials - supporting your compliance with USP <232>/<233> and ICH Q3D guidelines.

What Can Element Offer You For Elemental Impurities Testing and Analysis?

Key tests offered

Key tests offered

We deliver analytical impurities testing services essential for manufacturing compliance and product quality:

- Elemental impurity testing

- Implementation of ICH Q3D elemental impurities guideline

- USP <232>/<233> implementation of elemental impurity screening

- Method development and validation

- Limit test validation

- Quantitative method validation

- Semi-quantitative screening

- Trace metal analysis

- Targeted metals analysis

- Monograph (compendial) testing

- Extractables and leachables studies

- API and drug substance testing

- Raw materials testing

- Finished product testing

- Stability studies

- Batch and lot release testing

- Metal speciation

- Impurity characterization

Materials and products we test

Materials and products we test

Comprehensive testing capabilities cover your entire production chain, from raw materials through finished products. Our analysis includes APIs, drug substances, excipients, packaging materials, and container closure systems to identify potential sources of elemental impurities. We evaluate all materials that could introduce impurities, including those intentionally added during synthesis (such as catalysts), those potentially present in materials used to prepare drug products, and any elements that may be introduced from manufacturing equipment or container closure systems.

Methods and solutions offered

Methods and solutions offered

Our advanced sample preparation techniques include closed-vessel microwave digestion, acid digestion, base digestion, solvent extraction, and reflux extraction. These methods achieve superior detection limits - sub-ppb for elements like calcium and sodium, and sub-ppt for select applications. Our scientists develop and validate customized methods for challenging APIs and complex matrices, particularly those with poor solubility.

Elemental impurities sample preparation techniques:

- Closed-vessel microwave digestion

- Open-vessel microwave digestion

- Wet chemical digestion

- Acid digestion

- Base digestion

- Solvent extraction

- Reflux extraction

Cutting-edge equipment we use

Cutting-edge equipment we use

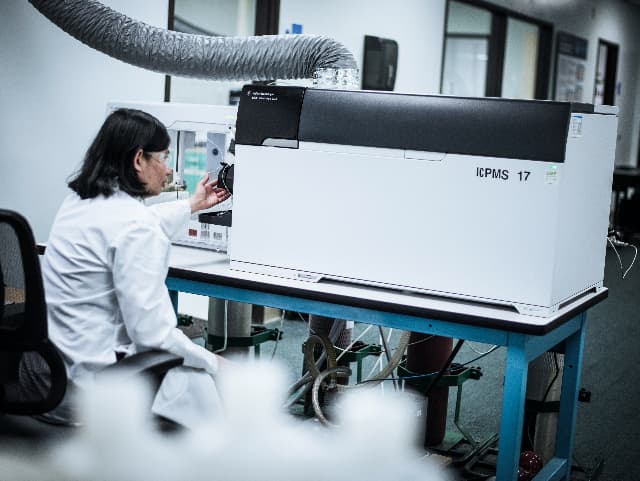

State-of-the-art ICP-MS technology coupled with three collision gases enables detection of elements typically obscured by polyatomic interferences, such as sulfur and silicon. Our advanced microwave digestion systems handle challenging matrices including plastics, lubricants, and complex pharmaceutical formulations. This specialized equipment allows for detection limits in the sub-parts per billion range for elements such as calcium, sodium, potassium, and silicon.

Which labs offer this service

Which labs offer this service

Our team operates from Life Sciences hubs across the world, providing global access to our expert capabilities. Find your nearest Life Sciences hub on our Locations Page.

Risk assessment expertise

Standards we test to and materials we test

- USP <232> and <233>

- ICH Q3D guidelines

- EMEA requirements

- BPOG expectations

Raw materials and APIs

- Active pharmaceutical ingredients

- Drug substances

- Raw materials

- Catalysts

- Manufacturing materials

Finished products

- Small molecule drugs

- Large molecule drugs

- Biologics

- Pharmaceuticals

Packaging components

- Container closure systems

- Plastic materials

- Lubricants

- Manufacturing equipment

Target elements for analysis

Recommended target elements per ICH Q3D, USP <232>, EMEA, BPOG, and other industry expectations:

- Lithium (Li)

- Aluminum (Al)

- Silicon (Si)

- Vanadium (V)

- Chromium (Cr)

- Manganese (Mn)

- Iron (Fe)

- Cobalt (Co)

- Nickel (Ni)

- Copper (Cu)

- Zinc (Zn)

- Arsenic (As)

- Molybdenum (Mo)

- Cadmium (Cd)

- Tin (Sn)

- Antimony (Sb)

- Barium (Ba)

- Mercury (Hg)

- Lead (Pb)

Additional recommended target elements if known to be present or potential for introduction per ICH Q3D, USP <232> and BPOG:

- Selenium (Se)

- Ruthenium (Ru)

- Rhodium (Rh)

- Palladium (Pd)

- Silver (Ag)

- Tungsten (W)

- Osmium (Os)

- Iridium (Ir)

- Platinum (Pt)

- Gold (Au)

- Thallium (Tl)

Other elements available as target analytes:

- Beryllium (Be)

- Boron (B)

- Sodium (Na)

- Magnesium (Mg)

- Phosphorus (P)

- Sulfur (S)

- Chlorine (Cl)

- Potassium (K)

- Calcium (Ca)

- Titanium (Ti)

- Germanium (Ge)

- Bromine (Br)

- Strontium (Sr)

- Zirconium (Zr)

- Iodine (I)

- Bismuth (Bi)

- Thorium (Th)

- Uranium (U)

Your Challenges, Our Solutions

Advanced analytics for complex matrices

Streamlined regulatory compliance

Precision detection achieved

Quality assurance delivered

Why Choose Element

Global regulatory expertise

Advanced analytical capabilities

Customized solutions

End-to-end support

But don't just take our word for it

See what others want to say about partnering with Element

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Pharmaceutical Testing Services

Element leads the way in pharmaceutical testing services, delivering trusted expertise from prototype to analysis and finished product. With 150+ global pharmaceutical experts and 30+ years of experience.

Trace Metal Testing and Analysis Services

Element offers trace metal testing and impurity analysis services, addressing safety, compliance, and contamination challenges for pharmaceutical products with advanced techniques and global expertise.

Pharmaceutical Quality Control Testing

Element provides pharmaceutical quality control testing, covering raw materials, APIs, and finished products. Our expert analytical development and validation help meet regulatory requirements and support all phases of product development.

Metals Speciation Analysis

Element offers advanced metal speciation analysis, providing detailed data on toxicity and bioavailability to support risk assessments in pharmaceuticals, biologics, and other industries.