EMC vs EMI Testing, What’s the Difference?

Ever wondered why terms like Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) are often intertwined? These two core concepts, crucial for protecting your electronic devices from interference, are closely related - but it is important to understand that EMC and EMI are not the same. So, what exactly is EMI, and how does it differ from EMC? In this article, Element expert Steve Hayes discusses the critical differences between EMC and EMI and explores which one is most effective for minimizing risk in different scenarios.

What’s the Difference Between EMC and EMI?

The purpose of EMI and EMC tests is to ensure that electronic and electrical devices, systems, and equipment can operate properly and coexist in their intended electromagnetic environments without causing or suffering from unacceptable levels of electromagnetic interference. These tests are crucial for various reasons:

- Ensuring products operate without interference.

- To comply with regulations and standards.

- Improving reliability and safety.

- To verify compatibility with other devices.

- Maintaining customer satisfaction.

What is Electromagnetic Compatibility (EMC)?

- Emissions: EMC considers the electromagnetic energy emitted by a device during its operation. This includes signals radiated through the air or conducted along cables.

- Immunity: On the other side of the EMC equation is immunity. This involves the device's ability to continue functioning correctly despite being exposed to electromagnetic disturbances from other sources, such as nearby transmitters or electrical equipment.

Fundamentally, the compatibility aspect ensures that we can have one electrical device used in close proximity to another electrical device without causing electrical interference.

What is Electromagnetic Interference (EMI)?

Electromagnetic Interference (EMI) arises from electromagnetic disturbances, impacting the functionality of electronic devices. These disturbances can stem from various sources, including environmental factors like electrical storms or other electronic devices/systems. If the interference occurs within the radio frequency spectrum, it's commonly termed Radio Frequency Interference (RFI).

Electromagnetic interference (EMI) can be categorized into several types based on their sources and characteristics. Some common types of electromagnetic interference include:

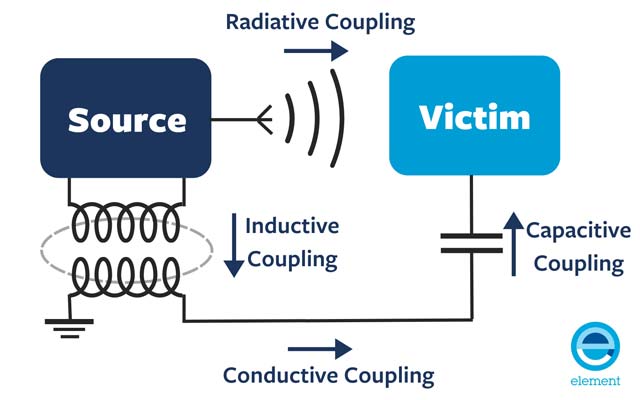

- Radiated EMI: Electromagnetic interference emitted as waves through the air, often from devices like radios or wireless routers.

- Conducted EMI: Interference conducted along wires or cables, typically caused by electrical devices such as motors or power supplies.

- Coupled EMI: Interference transferred from one circuit or transmission line to another through electromagnetic fields, leading to crosstalk or signal distortion.

These types of interference can disrupt electronic systems and communication networks, requiring mitigation strategies like shielding and filtering for optimal performance.

Determining Which EMI/EMC Test to Use

The device’s intended application will determine the exact type of testing required.

Key questions to ask are:

- Where is this product going to be used?

- With what/whom is it going to interfere?

- How will the energy travel from the product to its “victim”?

The two key methods that electromagnetic activity or ‘energy’ can reach a product through are the air (radiative coupling) or the cabling (conductive coupling). The standards used are therefore based primarily on radiated and conducted tests.

How to Design For EMI & EMC to Minimize Risk?

Electromagnetic compatibility (EMC) and interference (EMI) are both extremely important design considerations. Failing to consider them in the initial stages of product development can result in the time-consuming and costly need to redesign the product at a later stage to meet EMC/EMI specification tests and prevent product failure or safety risk.

If a product must be redesigned, it can be prohibitively expensive and result in delays to market and a loss in consumer confidence.

Bad product design (from an EMC or EMI perspective) would be when earthing, filtering, and shielding have not been considered. The result of this would include product failure during tests and in the real world would mean that the product would be unreliable and not work as intended.

Good product design incorporates the application of basic EMC principles such as effective shielding, earthing, and filtering will simultaneously improve electromagnetic immunity and reduce electromagnetic emissions, whilst minimizing risk.

Conclusion

Understanding the distinction between Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) is crucial for ensuring the seamless operation of electronic devices in their intended environments because it allows engineers and designers to effectively manage the risks associated with electromagnetic disturbances.

While EMI focuses on disruptions caused by electromagnetic disturbances to device performance, EMC evaluates a device's ability to function without affecting neighboring devices. This differentiation is essential because it enables targeted mitigation strategies to be implemented.

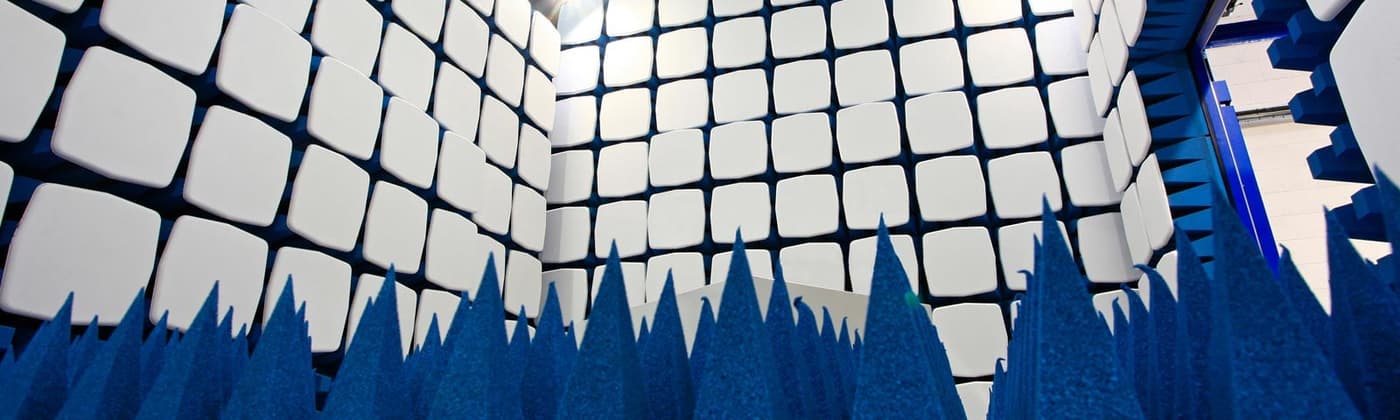

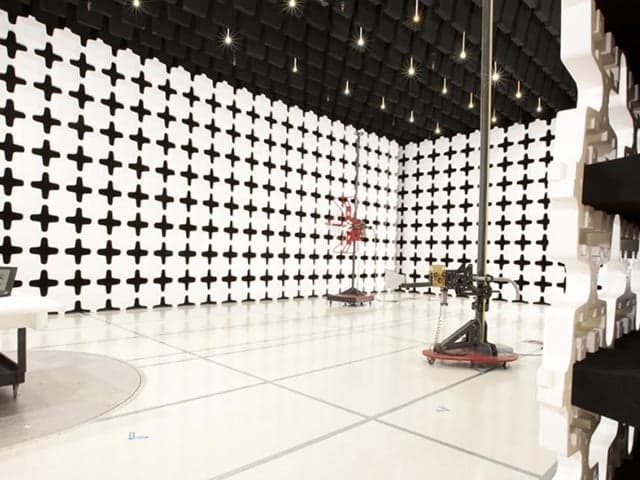

Our laboratories and EMC test facilities hold ISO/IEC 17025 accreditation from UKAS, NVLAP, A2LA, or DAkkS. We're recognized by authorities like the European EMC Directive, UK EMC regulation, FCC, and appointed as a Technical Service by the Vehicle Certification Agency.

For advice and support on EMC and EMI testing and compliance or Advisory Services, please contact us. To learn more about our expertise in this field, please visit our About Us page.

Related Services

Electromagnetic Compatibility (EMC) Testing & Electromagnetic Interference (EMI) Testing & Certification

Element provides accredited EMC and EMI testing and certification services, helping businesses meet regulatory requirements, reduce costly redesigns, and bring products to market faster through expert compliance support.