Rubber, Polymer, & Plastic Testing

Transform your polymer and plastic products from concept to reality with comprehensive testing solutions that match your exact needs. Our advanced characterization techniques and decades of expertise help you validate materials, maintain quality, and meet regulatory requirements - all while accelerating your time to market.

What is Rubber, Polymer, & Plastic Testing for Pharmaceuticals at Element?

Polymer and plastic testing involves analyzing materials' chemical composition, physical properties, and performance characteristics to validate quality and compliance. At Element, we provide comprehensive polymer characterization and testing services using advanced analytical techniques to support your product development, quality control, and regulatory requirements.

What Can Element Offer You for Rubber, Polymer, & Plastic Testing?

Materials and products we test

Materials and products we test

Our testing capabilities span the complete range of polymer materials, from basic resins to complex composites. Our experts identify polymer resins, inorganic fillers, stabilizers, colorants, additives, impact modifiers, and other components in your materials. We analyze raw materials through finished products, including medical-grade polymers, packaging materials, and industrial plastics. Our expertise covers thermoplastics, thermosets, elastomers, and custom compounds. From simple polymer identification to complex material characterization, we support all your testing needs across industries.

Key tests offered

Key tests offered

We provide comprehensive chemical and physical testing essential for your success, including molecular weight determination, thermal analysis, mechanical properties testing, and chemical composition analysis. From initial material characterization to ongoing quality control, our testing services support every stage of your development cycle. We offer:

- Chemical analysis and analytical testing

- Polymer particle analysis

- Polymer characterization and testing

- Surface analysis testing

- Weathering and aging testing

- Chemical resistance testing

- Molecular weight determination

- Chemical bonds and structure analysis

Plastic and Polymer Testing Services:

- Chemical Analysis and Analytical Testing for Polymers

- Good vs. Bad Lot Investigations

- Polymer Method Development & Validation

- Non-Routine Testing of Polymers

- Polymer Particle Analysis & Testing

- Polymer Coatings Comparability Testing

- Polymer Surface Analysis Testing

- Weathering & Aging Testing for Polymers

- Chemical Resistance Testing

- Molecular Weight Determination (molecular weight distribution, polydispersity)

- Chemical Bonds, Molecular Structure, & Composition (Including Crosslink Density)

- Total Molecular Weight

- End Group Analysis

- Co-Polymer Backbone Chemistry, Comonomer Contents/Ratios, Polymer Blends

- Additive & Resin Identification

- Plastic Testing for Tensile Strength, Modulus Compression, and Elongation

- Chemical Family, Including Base Polymer Characterization

- Polymer and Composite Material Characterization

- Additive Analysis

- Antioxidant Testing

- Color Body Determination

- Osmometry

- Total Organic Carbon

- Determination of Mixture Compositions

- Evaluation of Product or Material Stability

Polymer Safety Testing:

- Quantitation of reproductive toxins including bisphenol-A (BPA) and diethylhexyl phthalate (DEHP) in polymer materials

- Bisphenol-A (BPA) Detection and Testing

- Plasticizers Including Phthalates

- Characterization of volatile organic compound (VOC) levels

Polymer Failure Analysis Investigations:

- Contaminant or Impurity Identification

- Off-Color & Off-Odor Problems

- Facility Leaks (Broken PCV or ABS Water Lines, drains, etc.)

Extractables & Leachables Testing:

- Plastics Migration Testing & Food Contact Services

- Packaging Testing

- Caulk, Sealant, Elastomer Interactions in Clean Rooms and Medical Facilities

Polymer Medical Support Services:

- Medical Device Polymer Materials Testing

- Pharmaceutical Polymer Analysis Including Coatings

- Polymer Regulatory & Consulting Services

Polymers & Plastics Physical Testing:

- Material Hardness

- Tensile Properties (Strength)

- Yield Strength, Adhesive Strength

- Ductility, Compressibility

- Cross-Sectional Multiple Layer-Film Thickness Analysis

- Thermal Properties (Crystallinity, Glass Transition, Melting Point, Thermal Expansion)

Methods and solutions offered

Methods and solutions offered

Gain access to customized testing protocols using our extensive array of proven analytical techniques like FTIR spectroscopy, chromatography, and thermal analysis. We tailor our methods to your specific requirements, delivering precise results for product development, regulatory compliance, or troubleshooting needs.

Polymer characterisation and testing:

Element's plastic testing labs use a wide range of techniques to identify the components of a material, including polymer resins, inorganic fillers, stabilizers, colorants, additives, impact modifiers, and more. Your specific testing needs will be met with tailored processes. Our analysis methods and techniques include:

- FTIR Spectroscopy

- Gas Chromatography Mass Spectrometry (GC-MS)

- Liquid Chromatography Mass Spectrometry (LC-MS)

- Gel Permeation Chromatography (GPC)

- Differential Scanning Calorimetry (DSC)

- FID/TCD/ECD

- Mass Spectrometry (including Pyrolysis)

- Optical microscopy

- Optical testing - color, haze, and gloss

- Thermogravimetric analysis (TGA)

- High-performance liquid chromatography (HPLC)

- Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Spectroscopy (EDS)

- Pyrolysis (MSD)

- Nuclear Magnetic Resonance (NMR) spectroscopy (1H, 13C, 19F, 29Si)

- Ultraviolet-visible (UV-Vis) spectroscopy

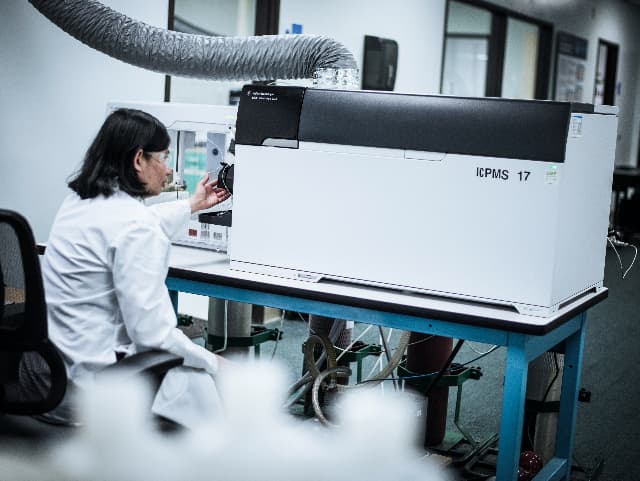

- ICP-MS and ICP-OES/AES elemental and trace metal analysis

- Rheological testing (viscoelastic properties, stress relaxation, melt viscosity, melt flow rate)

- Physical testing - density and hardness

- Gas separation and liquid separation techniques for extractables and leachables

- Microscopy (optical microscopy, stereo microscopy, scanning electron microscopy, energy dispersive X-ray microscopy, transmission electron microscopy)

- Ion chromatography (IC)

- Wet chemistry, such as Karl Fischer titration

- Tensile testing (yield, ultimate strength, ultimate elongation, toughness, fracture)

- Thermal properties testing (glass transition temperature, melting temperature, softening temperature, specific heat, degradation temperature, degradation rate, weight loss, thermal expansion coefficient, crystallinity, crystallization, phase transitions)

- Mechanical properties testing (yield, ultimate strength, ultimate deformation, toughness, fracture)

- Flash point measurement

- Aerosol flammability testing (US, Canadian, EU, and GHS Standards)

Quality control and regulatory support:

Partner with our experienced analysts for comprehensive quality control testing and more. Our abilities go beyond reporting to provide scientific research and consultancy services. We help you maintain consistent product quality and meet compliance requirements across medical devices, packaging, and other regulated applications. Our team provides expert guidance through complex regulatory requirements while maintaining the highest standards of quality control. We offer specialized support for:

- Medical device polymer materials testing

- Pharmaceutical polymer analysis including coatings

- Packaging testing and food contact services

- Polymer safety testing

- Quantitation of reproductive toxins

- Characterization of volatile organic compounds

- Extractables and leachables testing

- Plastics migration testing

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art analytical instruments include:

- spectroscopy systems (FTIR, NMR, UV-Vis)

- Chromatography equipment (GC-MS, LC-MS, GPC)

- Thermal analysis tools (DSC, TGA)

- Microscopy systems (SEM, TEM, optical)

- Rheological testing equipment

- Physical testing instruments for density and hardness

- Mechanical testing systems for tensile strength and compression

Which labs offer this service

Which labs offer this service

Our team operates from Life Sciences hubs across the world, providing global access to our expert capabilities. Find out where your nearest Life Sciences hub is on our Locations Page.

Standards we test to and materials we test

Aerosol flammability testing standards:

- US Standards

- Canadian Standards

- EU Standards

- GHS Standards

We test a comprehensive range of polymer and plastic materials including but not limited to:

- Acetal Resins

- Acrylic Resins

- Acrylonitrile-butadiene-styrene (ABS) Resins

- Alkyd Resins

- Allyl Resins

- Amino Resins

- Amino-aldehyde Resins

- Butadiene Copolymers

- Carbohydrate Plastics

- Casein Plastics

- Cellulose Acetate Resins

- Cellulose Nitrate Resins

- Cellulose Propionate Resins

- Cellulose Resins

- Cellulose Xanthate (Viscose)

- Coal Tar Resins

- Coumarone-indene Resins

- Cresol Resins

- Cresol-furfural Resins

- Custom Compounding Resins

- Dicyandiamine Resins

- Diisocyanate Resins

- Elastomers

- Epichlorohydrin Bisphenol

- Epichlorohydrin Diphenol

- Epoxy Resins

- Ester Gum

- Ethylcellulose Plastics

- Ethylene-vinyl Acetate Resins

- Fluoro-polymer Resins

- Fluorohydrocarbon Resins

- Ion-exchange Resins

- Ionomer Resins

- Isobutylene Polymer Resins

- Lignin Plastics

- Melamine Resins

- Methyl Acrylate Resins

- Methylcellulose Resins

- Methyl Methacrylate Resins

- Nitrocellulose (i.e., Pyroxylin) Resins

- Nylon Resins

- Petroleum Polymer Resins

- Phenol-formaldehyde Resins

- Phenol-furfural Resins

- Phenolic Resins

- Phenoxy Resins

- Phthalic Alkyd Resins

- Phthalic Anhydride Resins

- Plastics & Synthetic Resins Regenerating, Precipitating, & Coagulating

- Polyacrylonitrile Resins

- Polyamide Resins

- Polycarbonate Resins

- Polyester Resins

- Polyethylene Resins

- Polyethylene Terephthalate (PET) Resins

- Polyhexamethylenediamine Adipamide Resins

- Polyisobutylene Resins

- Polymethacrylate Resins

- Polypropylene Resins

- Polystyrene Resins

- Polytetrafluoroethylene Resins

- Polyurethane Resins

- Polyvinyl Alcohol Resins

- Polyvinyl Chloride (PVC) Resins

- Polyvinyl Halide Resins

- Polyvinyl Resins

- Propylene Resins

- Protein Plastics

- Pyroxylin (i.e., Nitrocellulose) Resins

- Resins, plastics

- Rosins (i.e., Modified Resins)

- Silicone Resins

- Soybean Plastics

- Styrene Resins

- Styrene-Acrylonitrile Resins

- Tar Acid Resins

- Thermoplastic Resins & Plastics Materials

- Thermosetting Plastics Resins

- Urea Resins

- Urea-formaldehyde resins

- Vinyl Acetate Resins

- Vinyl Chloride Resins

- Vinyl Resins

- Vinylidene Resins

Your Challenges, Our Solutions

Quality control made effortless

Material characterization mastered

Regulatory requirements simplified

Development cycle optimized

Why Choose Element

World-class analytical expertise

Comprehensive testing solutions

Customized approach

Trusted partnership

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Extractables and Leachables Testing Services

Element provides tailored extractables and leachables testing (E&L) studies to ensure patient safety and compliance with regulatory requirements.

Trace Metal Testing and Analysis Services

Element offers trace metal testing and impurity analysis services, addressing safety, compliance, and contamination challenges for pharmaceutical products with advanced techniques and global expertise.

Material Sciences Testing

Our material testing laboratories provide a complete suite of material testing services for pharmaceutical companies.

Polymeric Failure Analysis Services for Medical Devices

Element's experts provide failure analysis of polymer-based medical devices, which is critical to ensuring that process or material improvements can be made to prevent repeated failures.

Chemical Characterization

Element's chemical characterization services help identify, analyze, and ensure the quality of materials, addressing challenges in purity, composition, and contaminants with advanced techniques and expertise.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.