Stress analysis of low-cost, low-weight safety device used to deflect jet fires

The Challenge

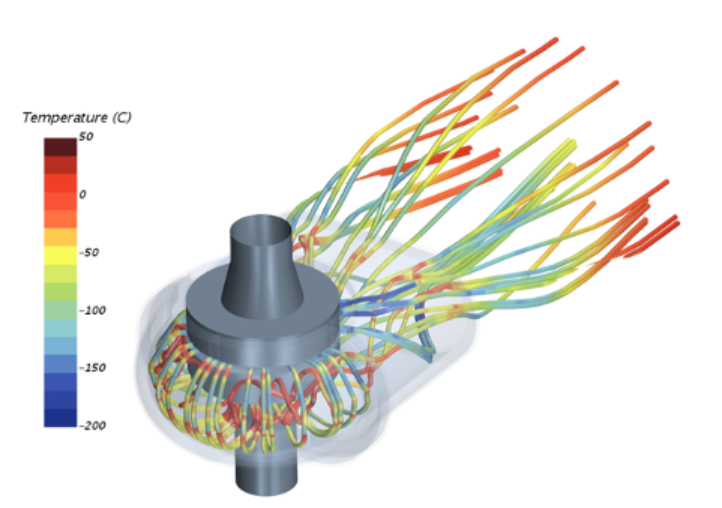

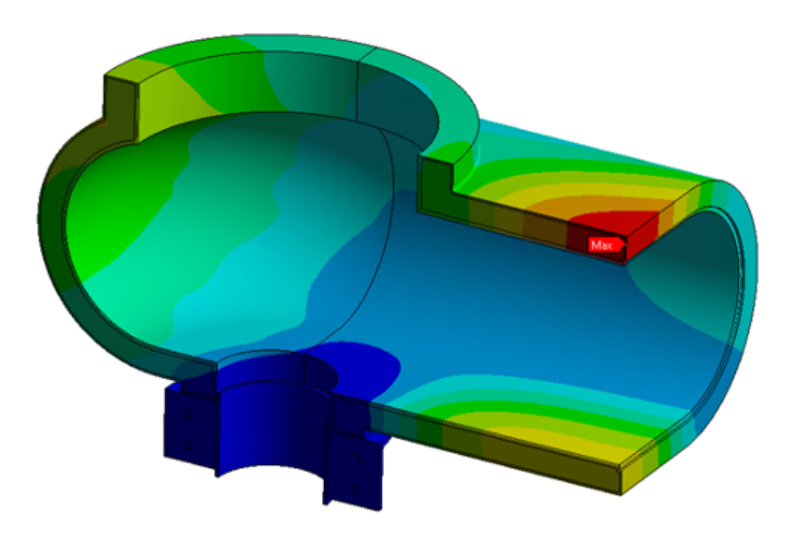

The customer was developing a safety protection device that would deflect jet fires from leaking pipe flanges away from personnel and equipment. The device had to withstand high pressures from the leak as well as extremes of low and high temperature, with minimal metallic content.

The Solution

The principal challenge was to demonstrate that the device would survive and function in the event of a worst-case accident. Element’s team of fluid dynamics experts simulated the leak and the flows and temperatures in the flange cover, then linked these results to stress analysis models to predict the performance of the device. Whilst some essential changes were identified to maintain integrity, it was possible to confirm that the basic design was sound.

The Result

The effectiveness and integrity of the device were clearly demonstrated to the relevant approval body, allowing the customer’s client to proceed with a design that saved millions of dollars by dispensing with a heavy structural firewall. The customer was also able to take the approved design and promote it to other operators worldwide.

Related Services

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.