Design and Development Services

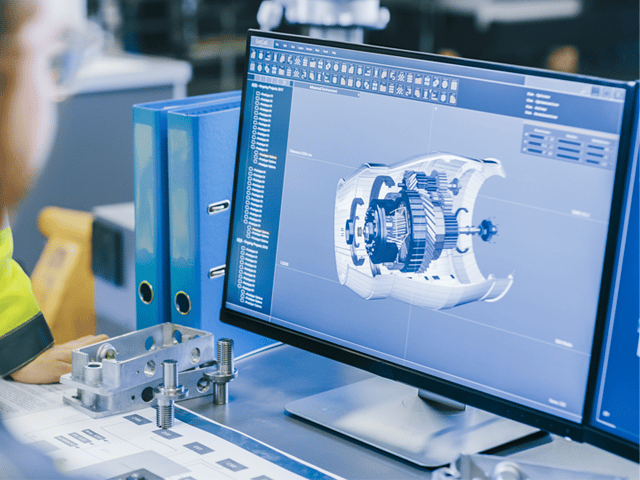

Transform your design concepts into market-ready solutions with Element's integrated Design and Development Services. Our hands-on technical partnership combines advanced CFD, FEA, and CAD modeling with bespoke software solutions and digital twins, accelerating your development timelines while reducing costly errors through end-to-end precision engineering from concept to reality.

What are Design and Development Services at Element?

Design and Development Services encompass comprehensive engineering solutions that integrate advanced modelling, simulation, and software development to optimize product design and performance. Here at Element Digital Engineering, we provide state-of-the-art design technologies combined with traditional engineering excellence to handle complex design challenges across diverse industries, ensuring your projects not only meet but exceed expectations through our integrated approach to transform your concepts into reality.

What Can Element Offer for Design and Development Services?

Methods and solutions offered

Methods and solutions offered

At Element, you can benefit from our integrated methodology that seamlessly combines digital innovation with proven engineering practices. Our approach includes:

- Precision modelling - Advanced CFD, FEA, and CAD capabilities for detailed simulations

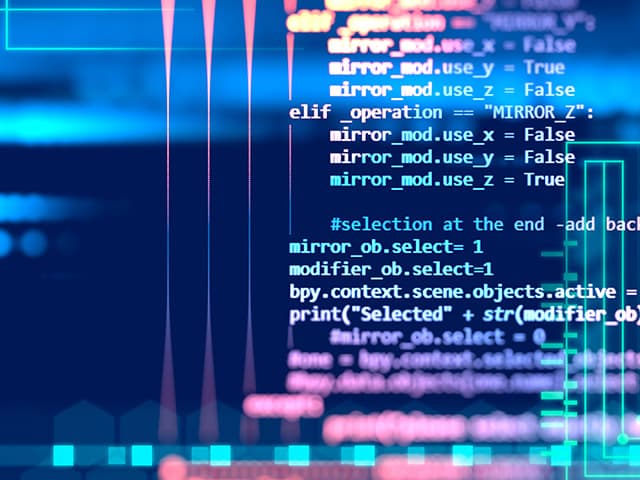

- Bespoke software solutions - Custom development for enhanced design accuracy and operational efficiency

- Digital twins implementation - Real-time analysis and lifecycle management

- Design optimization - Simulation-driven design and parametric optimization

- Change management - Proven strategies to implement design modifications smoothly

Products and systems we test

Products and systems we test

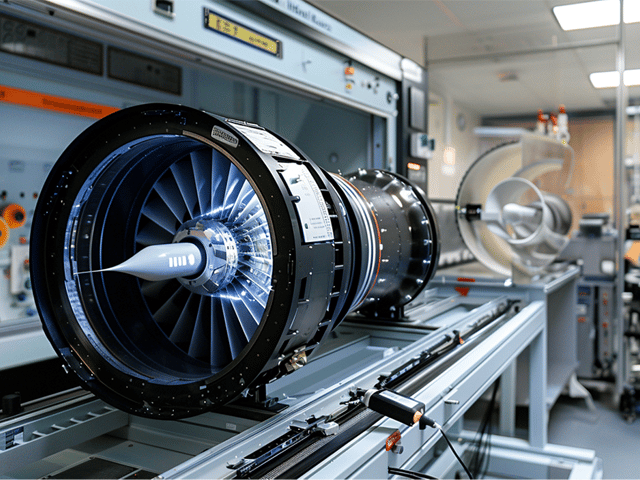

We analyze and validate components across diverse engineering applications, from hydrogen fuel cell cores to aerodynamic systems. Our capabilities include:

- Hydrogen fuel cell components - Flow path analysis and core optimization

- Aerodynamic systems - Rolling stock and transportation applications

- Industrial machinery parts - Mining and processing equipment

- Digital prototypes - Virtual validation before physical testing

- Engineering test systems - Custom rig components and validation

Key tests offered

Key tests offered

Our precision testing portfolio combines simulation with real-world validation capabilities. We offer:

- Computational Fluid Dynamics (CFD) - Flow optimization and thermal analysis

- Finite Element Analysis (FEA) - Structural integrity and stress testing

- Digital twin validation - Real-time performance monitoring

- Parametric optimization - Design refinement through simulation

- Aerodynamic performance assessment - Transportation and industrial applications

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art technology platforms deliver detailed simulations and innovative solutions beyond traditional design capabilities. We utilize:

- Advanced CFD modelling systems - For complex flow analysis and optimization

- Sophisticated FEA analysis tools - Structural validation and performance prediction

- Comprehensive CAD platforms - Integrated design and modelling capabilities

- Bespoke software development environments - Custom solutions for your specific needs

- Digital twin technology - Real-time monitoring and lifecycle management systems

Combining Simulation with Physical Testing

Combining Simulation with Physical Testing

Element Digital Engineering is uniquely positioned within a wider group that provides physical insight to complement our modelling and simulation. Working with our colleagues, we generate assured outputs validated by physical test when you require it. Our global footprint allows us to provide this powerful combined service anywhere in the world, delivering end-to-end product development that takes your project from initial concept to market-ready product with efficiency and precision.

Products and systems we test

We analyze and validate components across diverse engineering applications, from hydrogen fuel cell cores to aerodynamic systems. Our capabilities include:

- Hydrogen fuel cell components - Flow path analysis and core optimization

- Aerodynamic systems - Rolling stock and transportation applications

- Industrial machinery parts - Mining and processing equipment

- Digital prototypes - Virtual validation before physical testing

- Engineering test systems - Custom rig components and validation

Your Challenges, Our Solutions

Complex Design Integration

Inefficient Design Changes

Limited Simulation Capabilities

Design Optimization Challenges

Element Experts at your service

Why Choose Element

Assured Physical Validation

Integrated Design Excellence

Bespoke Solution Development

End-to-End Partnership

270+Laboratories

8,500+ Experts

1,000+Accreditations

50,000+Customers

But don't just take our word for it

See what others have to say about partnering with Element

Frequently asked questions

How do digital twins improve design outcomes?

Digital twins provide real-time analysis and lifecycle management capabilities, allowing you to predict future operating data, improve performance, and maintain equipment integrity throughout the product lifecycle, ensuring your designs remain both innovative and practical.

What makes Element's design approach different from other providers?

Our unique integration within the wider Element Materials Technology group means we can combine advanced digital modeling with physical testing validation, providing assured outputs that pure-software providers cannot match, giving you confidence in both theoretical and practical design performance.

Can I access Element’s physical testing capabilities alongside my program with Element Digital Engineering?

Yes. Our Design and Development Services connect seamlessly with Element's broader testing and certification capabilities, providing you with a complete solution from digital design through physical validation and regulatory compliance. This integration reduces project complexity, accelerates timelines, and ensures your designs meet all necessary standards for successful market entry.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Digital Engineering Services

Element's Digital Engineering Services enhance reliability, reduce costs, and accelerate innovation through advanced simulations and data-driven insights. Our customized solutions streamline project lifecycles, ensuring optimized designs, regulatory compliance, and future-ready technology.

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Engineering Design Services

Enhance your design process with our Engineering Design Services. Our simulation-driven approach and advanced CAD techniques ensure optimal design solutions, reducing your time to market and enhancing product quality.

Software Development for Engineering Services

Discover how Element's custom software development for engineering drives innovation, cuts costs, and streamlines system integrations. From agile prototyping to digital twin technology, our tailored solutions support global customers, enhance performance, and improve reliability—helping you stay ahead in a competitive landscape.

Test Rig Design Services

Our Test Rig Design Services, tailored to simulate real-world conditions, can ensure your tests meet exact industry standards and operational needs.

Prototyping and Testing Services

Expert Prototyping and Testing Services from Element Digital Engineering: rapid fabrication, custom test rigs & regulatory compliance. Accelerate your product development today!