About Element Baltimore Materials Testing Laboratory

Element Baltimore is an internationally accredited, world-renowned, full-service failure analysis testing facility specializing in materials testing in accordance with numerous industry standards including ASTM, IPC and MIL-Specs.

If you have technical questions or require help designing a test plan, you will work one-on-one with our technical experts, many who chair industry standards writing committees including ASTM and IPC.

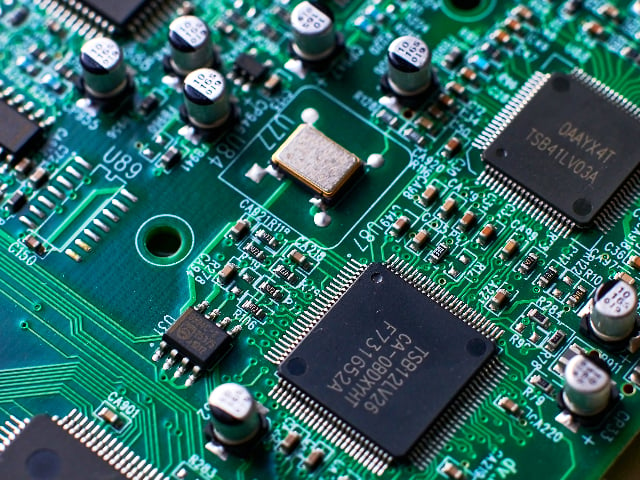

Printed Circuit Board / Assembly (PCB/PCA)

Printed circuit boards are the foundation for any printed circuit assembly. Our internationally accredited laboratory is approved for PCB testing to IPC-6012, IPC-6013, IPC-6016, IPC-6018, MIL-PRF-55110, MIL-P-50884, MIL-PRF-31032 or MIL-STD-810. This includes the bare PCB, the finished assembly (PCA), and the raw materials that comprise the PCB and PCA. We have been assessing board quality for over 30 years, in addition to performing full root cause failure analysis. To ensure the conformance of your product, it is recommended to engage in PCB/PCA testing when using a new supplier or changing a step of the manufacturing process.

ASTM Testing

With decades of experience as an ASTM testing lab for over 1,000 ASTM test methods, we are ISO 17025 and A2LA accredited. Our experts are members of many different ASTM committees and have participated for more than 20 years. We have contributed to the publication of hundreds of ASTM methods. Our specialty goes well beyond being a standard ASTM testing lab. In addition to testing in direct accordance with ASTM test methods, we offer unique solutions by modifying individual methods to meet the needs of our customers. This includes adapting methods to accommodate unique samples or requirements, as well as performing methods at non-standard environmental conditions.

Environmental Testing

Whether you are testing satellite components or solar cells that are intended to function in the most challenging desert setting, there is simply no substitute for environmental testing from Element Baltimore. When your components are expected to work in extreme temperature ranges and weather conditions, environmental testing including altitude, thermal shock / cycling, humidity, UV and other forms of dynamic testing can help you meet client expectations, adhere to regulatory standards and even avoid litigation.

Electrical Testing

We offer a full range of electronics testing to verify the safe and compliant operation of your electronic components and assemblies under all types of environmental conditions. We have the in-house expertise to supply you with all the information you need — including services that involve active monitoring and in-depth analysis. By accurately measuring everything from contact resistance to dielectric strength, we supply you with the tests and documentation you need to have full confidence in your electronic components.

IPC Testing & Training

Element Baltimore has a long history of testing and accreditation to various IPC standards and was the first IPC Qualified Test Laboratory for Validation Services. Our staff is heavily involved in industry groups such as the Assembly and Joining Committee, the 7-11 Test Methods Subcommittee, J-STD-004 Flux Specification Task Group, the SIR and Electrochemical Migration Task Group, the Ionic Conductivity task group, and all of the training development groups. We have the resources and experience to discuss, develop, perform, train to, and interpret IPC qualification and conformance to common standards.

Outgassing Analysis

Element Baltimore offers a proprietary approach to outgassing analysis, which includes testing in accordance with ASTM E595. Outgassing analysis is a critical service for customers in the space sector and involves a combination of technical expertise and effective control design to achieve the desired results. By quantifying the gasses released from specific materials, customers are able to better protect control surfaces and electronic systems. Additionally, we offer TQCM (Temperature controlled Quartz Crystal Microbalance) services and our Outgassing test stands allow for flexibility and customization against the standard methodology in terms of both temperature and vacuum level.

RTCA DO-160 Testing and MIL-STD-810 Testing

In addition to our ASTM and IPC work, we are equipped and accredited to offer our clients testing to sections 4, 5, 11, 13, and 26 of the RTCA DO-160 standard. The MIL-STD-810 sections 500 through 504, 507, 508 and 512 are also routinely tested by our laboratory.

Chemical Testing

Element Baltimore is a world-renowned chemical testing lab with expertise in composition, flammability, ion chromatography and more. To ensure your products' regulatory compliance and correct chemical composition, we are highly skilled at testing products to meet the standards of leading organizations such as ASTM International, UL, IPC and U.S. Department of Defense MIL-STD and/or MIL-SPEC.

Mechanical Testing

We regularly perform mechanical testing to provide our clients with full knowledge of the physical and mechanical limits of their products. By identifying vulnerabilities early in a product’s development, our mechanical testing services can help you develop a best-in-class product that sets you above your competitors. Whether you need to measure elasticity, impact resistance or another product characteristic, the scope of our mechanical testing means you can count on the integrity of your final product.

Compliance and capabilities at Element Baltimore

- Printed Circuit Boards (PCB)

- Printed Circuit Assemblies (PCA)

- Raw materials comprising PCBs and PCAs

- Satellite components

- Solar cells

- Electronic components

- Electronic assemblies

- Materials releasing outgassing gasses (space sector relevant)

- Chemical products (for composition, flammability, ion chromatography)

- Mechanical products (for elasticity, impact resistance, physical limits)

Printed Circuit Board (PCB) and Assembly Standards

- IPC-6012

- IPC-6013

- IPC-6016

- IPC-6018

- MIL-PRF-55110

- MIL-P-50884

- MIL-PRF-31032

- MIL-STD-810

ASTM Standards

- Over 1,000 ASTM test methods (ISO 17025 and A2LA accredited)

- ASTM E595 (Outgassing analysis)

Military and Aerospace Standards

- RTCA DO-160 (sections 4, 5, 11, 13, and 26)

- MIL-STD-810 (sections 500 through 504, 507, 508, and 512)

Chemical Testing Standards

- UL standards

- U.S. Department of Defense MIL-STD and MIL-SPEC

Other Standards

- Various IPC qualification and conformance standards

Download

Element Baltimore Brochure

Global expertise

Working with Element, you have access to our global network of materials testing and product qualification test experts. Meet our Engaged Experts.