Composite Curing Autoclave & Fabrication

Ensure your composites meet rigorous specs with our composite curing autoclave and fabrication services. We provide hands-on technical guidance, saving you time and cost by quickly validating mechanical properties and freeing your in-house autoclaves for production. Gain end-to-end convenience and seamless results for aerospace, automotive, and industrial applications through our precise autoclave process and expert support.

What is Composite Curing Autoclave & Fabrication at Element?

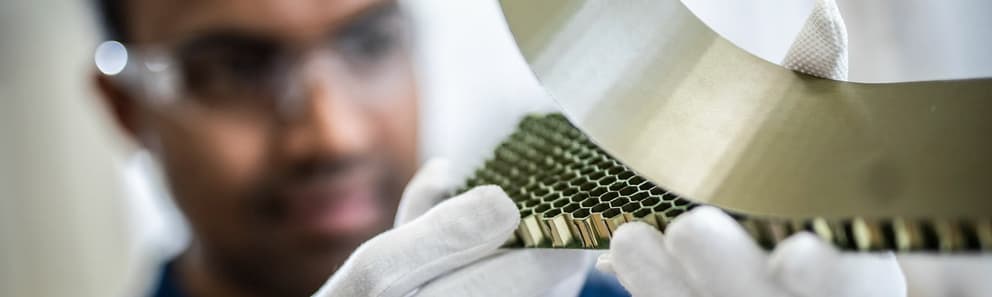

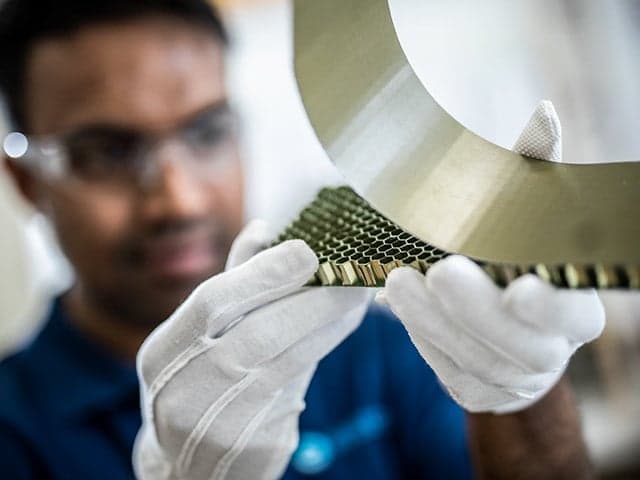

Composite materials manufacturing involves stacking carbon or glass fiber layers in specific sequences, embedding them in polymer matrices to create CFRP or GFRP laminates. At Element, we provide comprehensive fabrication services from manual lay-up through autoclave curing under precise pressure and temperature conditions to deliver composites with optimal mechanical properties. This quick and easy approach helps ensure your final parts are consistently manufactured to meet exact specifications.

What Can Element Offer You For Composite Curing Autoclave & Fabrication?

Key tests offered

Key tests offered

Our comprehensive testing capabilities include acceptance testing of raw materials and shelf life extension testing to validate durability and mechanical properties. We perform qualification testing to verify composites maintain their structural integrity under various environmental conditions, supporting your quality assurance needs and helping create final products with the exact mechanical properties your applications demand.

- Acceptance testing for composite raw materials

- Shelf life extension testing

- Durability validation

- Quality assurance testing

- Mechanical property verification

Materials we test

Materials we test

We test a comprehensive range of composite materials from raw materials to finished components. Our expertise covers carbon and glass fiber composites, pre-impregnated materials, and complex polymer matrix composites used across aerospace, automotive, energy, and industrial applications where performance and safety are paramount. By thoroughly testing these materials, we help you validate that your composites will maintain their durability in components and remain safe in practice throughout their lifecycle.

- Carbon fiber reinforced polymers (CFRP)

- Glass fiber reinforced polymers (GFRP)

- Pre-impregnated composite materials

- Polymer matrix composites

- Raw composite constituents

Methods and solutions offered

Methods and solutions offered

Element provides end-to-end composite fabrication services from manual lay-up of pre-impregnated materials through to precision autoclave curing. Our experienced technicians follow rigorous quality procedures to create properly merged CFRP and GFRP laminates that meet your exact specifications. We carefully control temperature and pressure during the curing process to achieve optimal mechanical properties while streamlining development time and maximizing manufacturing efficiency. This “quick and easy” testing approach helps lower costs and ensures you rapidly gain the insights you need.

- Manual lay-up of pre-impregnated materials

- Precision autoclave curing under controlled conditions

- Complete fabrication process management

- Custom stacking sequence implementation

- Polymer matrix embedding processes

R&D support and optimization

R&D support and optimization

Free up your in-house autoclaves for manufacturing by leveraging our R&D capabilities. Our experts help optimize your composite curing processes, material selection, and fabrication techniques to achieve desired mechanical properties while improving production efficiency and reducing development costs. We work closely with you to develop optimal stacking sequences and curing parameters tailored to your specific applications, allowing you to focus your resources on manufacturing while we handle the research and development testing.

- Custom R&D programs for composite optimization

- Curing process parameter development

- Material selection consultancy

- Production efficiency improvement analysis

- Development cost reduction strategies

Cutting-edge equipment we use

Cutting-edge equipment we use

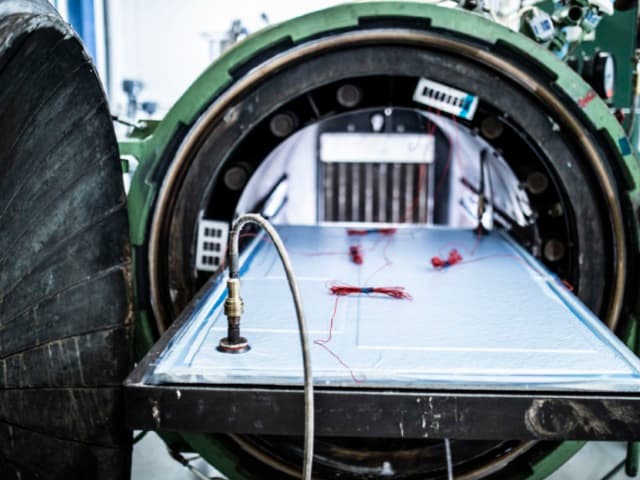

Our state-of-the-art autoclaves operate under precisely controlled temperature and pressure conditions to achieve optimal composite curing results. These specialized facilities allow us to process a wide range of composite materials efficiently, delivering consistent performance characteristics that meet or exceed industry standards across multiple sectors including aerospace, automotive, wind energy, medical, railway, and oil and gas industries where reliability and safety are essential.

- Advanced curing autoclaves

- Precision temperature and pressure control systems

- Specialized composite fabrication equipment

- Quality assessment instrumentation

- Materials handling systems optimized for composites

Which labs offer this service

Which labs offer this service

Our team operates from specialized composites testing labs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing hub on our Locations Page.

Materials We Test

- Carbon Fiber Reinforced Polymers (CFRP)

- Glass Fiber Reinforced Polymers (GFRP)

- Pre-impregnated composite materials

- Polymer matrix composites

Your Challenges, Our Solutions

Production efficiency without compromising R&D

Optimal properties through precision curing

Complex fabrication with consistent quality

Cost-effective access to expert capabilities

Why Choose Element

Specialized composite fabrication expertise

Manufacturing-focused testing approach

Comprehensive curing parameter control

Complete fabrication workflow mastery

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Flexural Testing for Composite Materials

Element provides flexural testing for composite materials, evaluating strength and stiffness to ASTM, ISO, and EN standards. Supporting aerospace, automotive, and renewable energy industries with expert testing solutions.

Mechanical Testing of Composites

Element provides expert mechanical testing for composite materials, ensuring strength, durability, and compliance with industry standards. Services include tensile, shear, compression, and fatigue testing.

Composite Damage Tolerance Testing

Reveal hidden flaws with composite damage tolerance testing and drop weight impact testing. Our fracture toughness and CAI methods ensure safety and reliability.

Testing Environmental Effects on Composites

Element's composite testing evaluates the impact of environmental factors like moisture, thermal cycling, and fluid exposure, helping industries predict material performance and durability in real-world conditions.

Examining Fiber-Reinforced Composite Materials

Element provides fiber-reinforced composite testing to identify defects, improve material quality, and reduce risk. Our experts use advanced evaluation methods to support manufacturers in achieving reliable, high-performance products.

Composite Sandwich Panel Test Methods

Reliable, ASTM-standard testing of composite sandwich panels to assess strength, durability, and adhesive bonds helping you ensure your materials meet real-world performance and quality requirements.