Vibration Testing Services

Ensure the safety and durability of your product. Element’s advanced vibration testing services replicate real-world scenarios, revealing potential issues before they occur. As a global single-source provider, we deliver unparalleled testing, guaranteeing your product excels in even the most challenging conditions.

What is Vibration testing at Element?

Vibration testing helps detect performance issues and potential failures in your products before they start. Controlled laboratory settings are used to simulate the actual conditions that a product or structure might encounter in the real world. By testing the response, you can ensure that your products are robust and will perform safely during operation or transit.

Element provides comprehensive vibration testing services across a range of frequencies and load conditions, from basic resonance searches to complex multi-axis simulations. Our laboratories conduct tests to verify structural integrity and performance under vibration. We offer testing for a variety of sectors, including but not limited to aerospace, defense, automotive, construction, and energy.

What can Element offer you for vibration testing?

Key tests offered

Key tests offered

We help companies meet a broad spectrum of standards, with testing tailored to their specific industry needs. Our capabilities include:

- Random Vibration

- Sinusoidal

- Resonance Search & Dwell

- Narrow Band Random on Random

- Sine-on Random

- Helicopter Rotor Frequency Simulation

- Gunfire Simulation

- Shock Response Spectrum (SRS)

- Sustained engine imbalance (SEI)

- Crack Propagation Measurement

- Blade-off vibration (engine fan blade loss and windmilling)

- Windmilling

- Crash safety

- Modeshape Analysis

- Frequency Checks

Products we test

Products we test

Element can conduct vibration testing for products and components across a wide range of industries, including:

- Aerospace components, with particular expertise in large aero engines and engine fan blade systems

- Automotive, rail and other transportation sector components

- Energy assets

Our testing equipment can handle components weighing up to 2 tons, with a 160kN thrust and 3kHz testing capabilities, allowing us to test both large-scale industrial components and complete assemblies, as well as individual mechanical parts.

Methods and solutions offered

Methods and solutions offered

We use a three-step process to identify the decisions that need to be made for a productive and cost-effective vibration test, to save money, improve reliability, and reduce time to market.

Our experts support you at every stage:

- Identify your crucial test areas: Based on your intended use, we help you determine which vibration profile will most reliably test the product.

- Address fixtures: Poor fixture design leads to unreliable results, so we offer various vibration table mounting patterns and can support custom fixture design.

- Stringent monitoring: We can place accelerometers on your product for more precise testing. We’ll plan for multiple response channels where you need them.

Bespoke solutions for your industry

Bespoke solutions for your industry

Navigating the complexities of vibration testing can be challenging, especially when industry specifications and standards are required. At Element, we understand the importance of ensuring the quality and reliability of your products. That's why our vibration testing services are tailored to meet the highest standards in the world's most crucial industries. If you're in the aerospace sector, our services align with the RTCA DO-160 standards. For automotive and transportation equipment, we adhere to the specifications of GM, Toyota, and SAE. Electronic product testing follows the rigorous criteria set by IEC and IEEE programs. Additionally, we cover a diverse array of ASTM, ISO, and BS standards for any product type

Cutting-edge equipment we use

Cutting-edge equipment we use

Accurate measurements are paramount, from aerospace engines to railway components. But acquiring this precise data requires specialized equipment. We understand the frustration of managing these complexities. That's why our vibration testing service employs advanced techniques, and tools facilitated by experts, ensuring accurate measurements for testing and detailed reporting for peace of mind.

We have a vast global network of shaker tables at various sizes. This includes the largest commercially available shaker in the UK, servicing up to 2 tons, with 160kN thrust and 3kHz testing. Our large capacity means we can offer extended test runs and faster delivery times, helping your products get to market efficiently.

Fixturing support: critical to testing accuracy

Element's laboratories keep a set of standard vibration table fixtures that work for a wide range of product and equipment types. Some of these include:

- Interface plates

- Tie bars

- Bookends

Basic vibration test fixtures can be quickly and easily installed, making them a popular choice for most test programs. In most of our facilities, internal machining services can be used to make basic modifications that keep tight programs on schedule.

When complex load points, mechanical loads or complex specimen design necessitates custom vibration test fixture design, our testing engineers and machinists work together to create custom test fixtures tailored to your product.

Standards we test to and products we test

Standards we test to include, but are not limited to:

- BellCore Telecordia

- British Standards Institute (BS)

- California OSHPD Code Application Notice

- Defence Standard (UK)

- Institute Of Electrical And Electronics Engineers (IEEC)

- International Code Council (ICC)

- International Electromechanical Commission (IEC)

- International Organization For Standardization (ISO)

- International Safe Transportation Association (ISTA)

- Japanese Industrial Standards (JIS)

- General Motors Worldwide (GMW)

- Military Standards (US)

- Radio Technical Commission For Aeronautics (RTCA)

- SAE International

- United Nations Recommendations On The Transport Of Dangerous Goods

- Verein Deutscher Ingenieure

Aerospace:

- Aero engines (specifically large ones)

- Engine fan blades

Transportation/Automotive:

- Railway components

- Automotive components

Energy assets

Construction infrastructure and building products

Your Challenges, Our Solutions

Product Failure Risk

Complex Compliance Requirements

Precision Testing Challenges

Time-to-Market Pressure

Element Experts at your service

Why Choose Element

Customizable Accelerometer Placement

Expert Three-Step Process

Comprehensive Test Data

Worldwide Presence, Local Excellence

2 tons

160kNthrust

3kHztesting frequency

But don't just take our word for it

See what others have to say about partnering with Element

Frequently asked questions

What can I expect when working with Element as a vibration testing supplier?

Per Element technical director David Lichtman, you can expect a truly collaborative experience and proactively managed program: “At Element, we strive to be a strategic partner, not just a test house. We can assist in test plan generation, fixture design, and fabrication, optimize control strategies, and facilitate complex unit operation (hydraulic, pneumatic) during testing."

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace RTCA DO-160 Testing

Element RTCA DO-160 Testing: Single-Source DO-160 Testing Performed In State-Of-The-Art Labs. Schedule Your Test Today.

Windmilling Testing Services for Aero Engines

Ensure your aero engine safety with Element's reliable windmilling testing using our advanced LDS V8 system for precise results and compliance assurance.

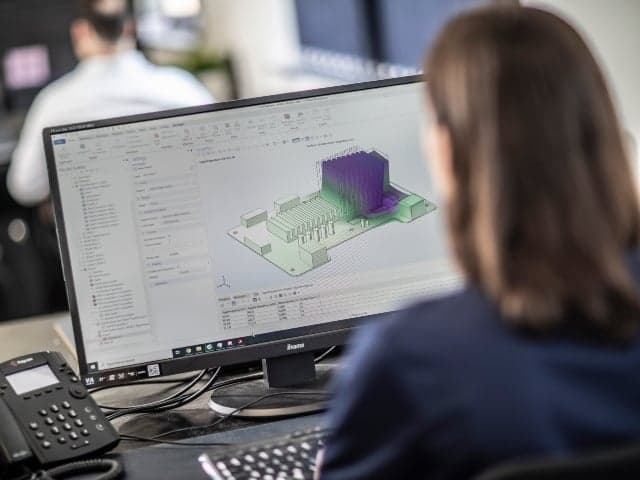

Finite Element Analysis (FEA) Services

Advanced Finite Element Analysis (FEA) services simulate product performance, optimize designs, and predict failures, addressing structural, thermal, and dynamic challenges across industries with expert solutions.

Dynamics Testing

Element's dynamics testing labs provide reliable, consistent data to the world's most critical industries. From aerospace to automotive to construction, we help ensure that your products are fit for purpose.

Seismic Testing Services

Our seismic testing services evaluate the performance of essential non-structural systems subject to shaking from earthquakes, railways, airports, and more.

Shock Testing Services

Protect your products with industry-leading shock testing up to 50,000g. Our expert team simulates real-world impacts to ensure your equipment performs in harsh environments.

Multi-Axial Simulation Table (MAST) Testing Services

Element's MAST testing replicates real-world vibrations in a controlled lab, helping automotive engineers assess durability, reduce development time, and refine vehicle components for safer, more reliable performance.

Automotive Buzz, Squeak, and Rattle (BSR) Testing

Element's BSR testing identifies and eliminates unwanted vehicle noise, improving customer satisfaction and reducing warranty claims. Our advanced testing technology simulates real-world conditions for accurate, reliable results.