Carbon Arc Testing

Validate your materials’ durability with precision carbon arc testing. Element's advanced Weather-Ometers simulate real-world exposure to sunlight and moisture, delivering fast, reliable results. With expertise across plastics, coatings, and automotive materials, we help you meet international standards while optimizing material performance.

What is Carbon Arc Testing at Element?

Carbon arc testing is an accelerated weathering method that evaluates material durability using arcing light sources to simulate sunlight exposure. At Element, we use Sunshine Carbon Arc Weather-Ometers (SWOM) with open-flame technology to replicate real-world environmental conditions, testing materials' resistance to UV, visible, and infrared radiation.

What Can Element Offer You For Carbon Arc Testing?

Key tests offered

Key tests offered

We provide carbon arc testing using Sunshine Carbon Arc Weather-Ometers (SWOM) to evaluate material integrity against sunlight and moisture exposure. Our testing simulates environmental conditions through controlled exposure to ultraviolet, visible, and infrared radiation. We specialize in both filtered and unfiltered carbon arc exposures for comprehensive material evaluation.

- Open flame carbon arc light testing

- Filtered carbon arc exposures for plastics

- Light and water exposure evaluation

- Weatherability testing for automotive parts

- Synthetic resin coating analysis

Materials we test

Materials we test

Our testing capabilities cover plastics, paints, coatings, synthetic resins, and window glass adhesives. We specialize in evaluating light-fastness durability and weathering resistance for polymeric materials used in automotive and industrial applications. Our expertise extends to testing non-metallic materials and synthetic resin parts for various industry sectors.

Methods and solutions offered

Methods and solutions offered

Our testing methods utilize open flame carbon arc light apparatus for material evaluation. We conduct filtered and unfiltered carbon arc exposures, analyzing material degradation and performance under accelerated weathering conditions. Our solutions are designed to meet international standards while providing detailed insights into material performance and durability.

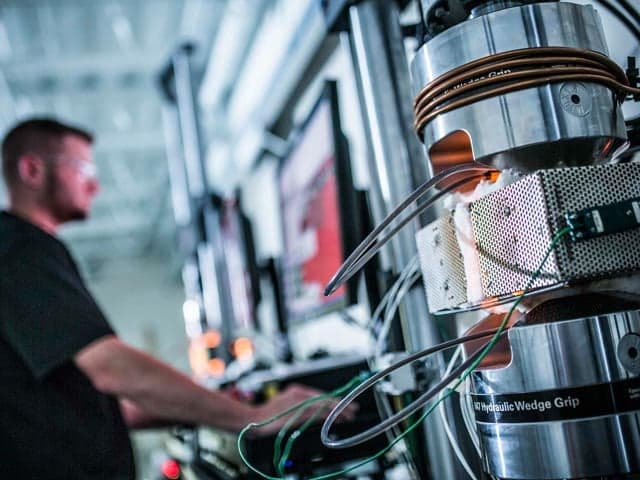

Cutting-edge equipment we use

Cutting-edge equipment we use

Our laboratories are equipped with Sunshine Carbon Arc Weather-Ometers (SWOM), utilizing open flame technology to deliver accurate and repeatable testing results that meet industry standards. These advanced instruments provide precise control over testing parameters, ensuring reliable simulation of environmental conditions.

Standards we test to and materials we test

Element is accredited to perform carbon arc testing to the following standards:

- ASTM G152: standard practice for operating open flame carbon arc light apparatus for exposure of nonmetallic materials

- ASTM D1499: standard practice for filtered open flame carbon arc exposures of plastics

- JIS B 7753: light exposure and light and water exposure apparatus (open flame carbon arc type)

- JIS D 0205: test method of weatherability for automotive parts

- NES M 0135: weatherability and light resistance test methods for synthetic resin parts

- NES M 0141: test method for coating of synthetic resin

- MES MN 201B: test method for plastic materials

- MES MN 350M: window glass adhesives

Automotive materials

- Synthetic resin parts

- Window glass adhesives

- Automotive plastics

Industrial materials

- Polymeric materials

- Paints and coatings

- Non-metallic materials

Your Challenges, Our Solutions

Need to Make Quicker Decisions

Staying Compliant Globally

Selecting Better Materials

Meeting Development Schedules

Why Choose Element

Global testing network

Comprehensive standards coverage

Materials expertise

Advanced equipment

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Accelerated Weathering Testing Services

Element's accelerated weathering testing services evaluate durability under harsh conditions, helping you mitigate premature product failures, maintain quality standards, and achieve confidence in real-world performance for consistent success.

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

Ultraviolet Exposure & UV Testing Services

Element's UV testing services simulate sunlight exposure to assess material durability. Gain critical insights into degradation, improve product longevity, and meet industry standards with precise, lab-controlled testing.

Xenon Arc Testing

Validate material durability faster with our xenon arc testing. Accelerate product development and prevent failures with UV and weathering simulation.

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.