Low Cycle Fatigue (LCF) Testing

Accelerate your product development with precise material performance data under high-stress conditions. Get comprehensive strain-life curves through advanced low cycle fatigue testing. Save time and resources with expert material analysis that helps predict component performance in real world applications

What is Low Cycle Fatigue (LCF) Testing at Element?

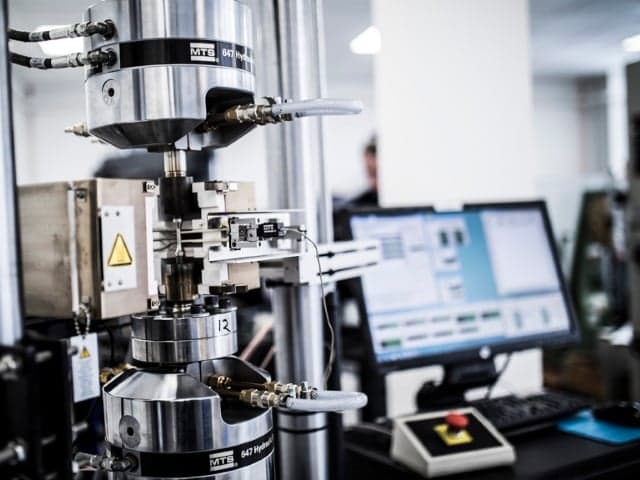

Low-cycle fatigue testing predicts how a material will wear and perform throughout its life, especially in high-stress environments. This testing is valuable for simulating specific scenarios and investigating real-world failures. At Element, we offer strain-controlled fatigue testing that complies with several industry specifications, including ASTM E606. Our precision equipment delivers accurate strain-life curves for your materials, ensuring reliable results.

What Can Element Offer You For Low Cycle Fatigue (LCF) Testing?

Materials and components we test

Materials and components we test

Our testing capabilities cover metals, alloys, and finished components across multiple industries. We can provide comprehensive analysis for both cylindrical and flat test specimens. Our expertise extends to components requiring specific fatigue performance validation for high-stress environments.

- Full range of metal alloys and composites

- Industrial and automotive components

- Medical device materials

- Aerospace-grade materials

- Precision-machined test specimens

Key tests offered

Key tests offered

We perform strain-controlled low cycle fatigue testing with targeted cycles up to 100,000, offering test frequencies between 0.25 Hz and 5 Hz. Our testing includes precise strain range control for developing accurate strain-life curves. ASTM E606 recommendations guide our approach, testing multiple specimens at varying strain levels to achieve statistical confidence.

- Complete strain-life curve development

- Multiple strain level testing

- Statistical analysis of results

- Comprehensive data acquisition

- Customized test frequencies

Methods and solutions offered

Methods and solutions offered

Our methodology encompasses complete specimen preparation, precision machining, and longitudinal polishing or grinding. We utilize advanced extensometers for exact strain measurement and control, following rigorous testing procedures to develop reliable strain-life curves. Each test is conducted under carefully controlled conditions to ensure repeatable results.

Which labs offer this service

Which labs offer this service

Our 8,500-strong team operates from Materials Testing Services hubs across the world including Europe and America, providing global access to our expert capabilities. Find out where your nearest Materials Testing Services hub is on our Locations Page.

In-house specimen preparation capabilities

In-house specimen preparation capabilities

From raw material blanking to final specimen machining and polishing, we handle every step of preparation in-house. Our comprehensive approach includes uniform-gage section preparation, surface finishing, and precise dimensional control throughout the manufacturing process.

Standards we test to and materials we test

Element offers LCF testing to a range of standards, including:

ASTM International

- ASTM E467, ASTM 606

British Standards

- BS 7270

General Motors Specifications

- GMW16704, GMW16705

International Organization for Standardization

- ISO 12106

Metals and alloys

- Metal alloys

- Industrial grade metals

- High-performance alloys

Components

- Automotive components

- Aerospace parts

- Medical devices

- Industrial machinery parts

Your Challenges, Our Solutions

Predicting real-world performance accurately

Ensuring compliance with industry standards

Obtaining fast, reliable results under pressure

Streamlining the material qualification process

Why Choose Element

Global reach, local service

Complete testing solutions

Advanced technical capabilities

Multiple standard compliance

Frequently asked questions

What is the difference between HCF and LCF fatigue?

High cycle fatigue (HCF) uses a low force load over a large number of cycles to cause failure. This generates an SN (stress/number of cycles) curve, which predicts how it will wear over time. In contrast, low cycle fatigue (LCF) uses high levels of force over a smaller number of cycles to stimulate a high-stress environment that might cause a more immediate break. This is measured with a strain vs. life curve.

What is the process for LCF fatigue testing to ASTM E606?

Before testing, the material is machined and polished or ground into cylindrical or flat test specimens with a uniform-gage section. These samples are then placed into a tension-compression endurance testing machine and subjected to repeated stress at a constant strain rate, following ASTM E606. Extensometers are used to measure deformation in the gage section, controlling the strain range.

Typical low-cycle fatigue tests run for no more than 100,000 cycles, with frequencies ranging from 0.25 Hz to 5 Hz, depending on the material and test requirements.

By testing multiple specimens at varying strain levels, strain-life (S/N) curves can be developed. ASTM E606 recommends testing at least ten samples for statistical confidence in these curves.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Fatigue Testing Services

Element's fatigue testing services analyze material durability under cyclic loads, providing insights into fatigue failure, fatigue life, and performance under real-world conditions.

High Cycle Fatigue (HCF) Testing

Element offers advanced high cycle fatigue testing to meet ASTM E466 standards, preventing material failures and improving product reliability under real-world conditions. Trusted expertise for robust performance.