Considerations for Measuring Glass Transition Temperature

In this article, Element expert John Moylan, senior specialist in aerospace polymer composites, explains how glass transition temperature (Tg) determines when materials shift from glassy to rubbery states. This guide details three critical testing methods - TMA, DSC, and DMA - helping manufacturers ensure polymers, composites, and electronics function properly across temperature ranges in real-world applications.

Glass transition temperature, or Tg is an important characteristic of polymeric materials. It marks the point at which a material changes from a glassy to a rubbery state, and influences many other material properties.

Glass transition temperature is characteristic of the type of polymer chain, the amount of crosslinking and chain length or molecular weight. Since most materials have a distribution of molecular weights and cross-linking, the Tg is not a discrete temperature, but rather a temperature range. A single temperature is generally reported for convenience, but the material will actually change properties over a range of temperatures.

Because of its close relation to strength and flexibility, it is critical to understand and apply the concepts of glass transition temperature during the product development lifecycle to ensure polymeric materials, components, and assemblies will function appropriately in the end use environment.

Is there an ideal Glass Transition Temperature (Tg)?

Determining an ideal glass transition temperature depends on the desired physical properties of the material itself, along with the application and environment in which the product or material will operate.

When materials like rubbers and elastomers need to retain flexibility, they should be used and stored above the glass transition temperature (otherwise, it runs the risk of becoming brittle). However, materials such as rigid plastics and composites should be used below the glass transition temperature. If used above that point, the heat will cause them to have lower modulus and a higher coefficient of thermal expansion. For composites, this causes lower mechanical resin based properties such as compression, shear and interlaminar tension. For electronic materials, printed wiring boards may be thermally stressed during assembly or use. This results in mechanical stresses in plated through holes, vias, leads and solder joints. For optimal reliability, a high Tg is important.

External factors, like humidity or moisture level, may also affect glass transition temperature. Because moisture tends to diffuse slowly through a material, it may act as a plasticizer and causes the material to reach an equilibrium moisture content based on the relative humidly of the exposure. This results in a lower glass transition temperature. Materials used in an office environment will only pickup moderate amounts of moisture during service life, compared to materials outdoors in a humid environment. Because of this, a low temperature (well below the cure temperature) drying or a controlled moisture exposure may be appropriate.

How is Glass Transition Temperature Testing Performed?

In order to determine the glass transition temperature of a material, one of several different test and reporting types may be used. The method used will largely depend on the type of results being sought, and what data is required in the final report.

The classical way of measuring glass transition temperature is to perform a series of mechanical tests over the expected temperature range. While there are several options for the test type, flexural strength or shear testing are the standard. Results are reported as a plot of flexural or shear modulus in relation to temperature. The glass transition temperature is indicated where there is a significant drop off in material strength.

Thanks to modern thermal analysis, testing for glass transition temperature has become significantly faster and cheaper in recent years. The most standard thermal methods for determining transition temperature are Thermomechanical Analysis (TMA), Dynamic Mechanical Analysis (DMA), and Differential Scanning Calorimetry (DSC).

Tg Testing Methods

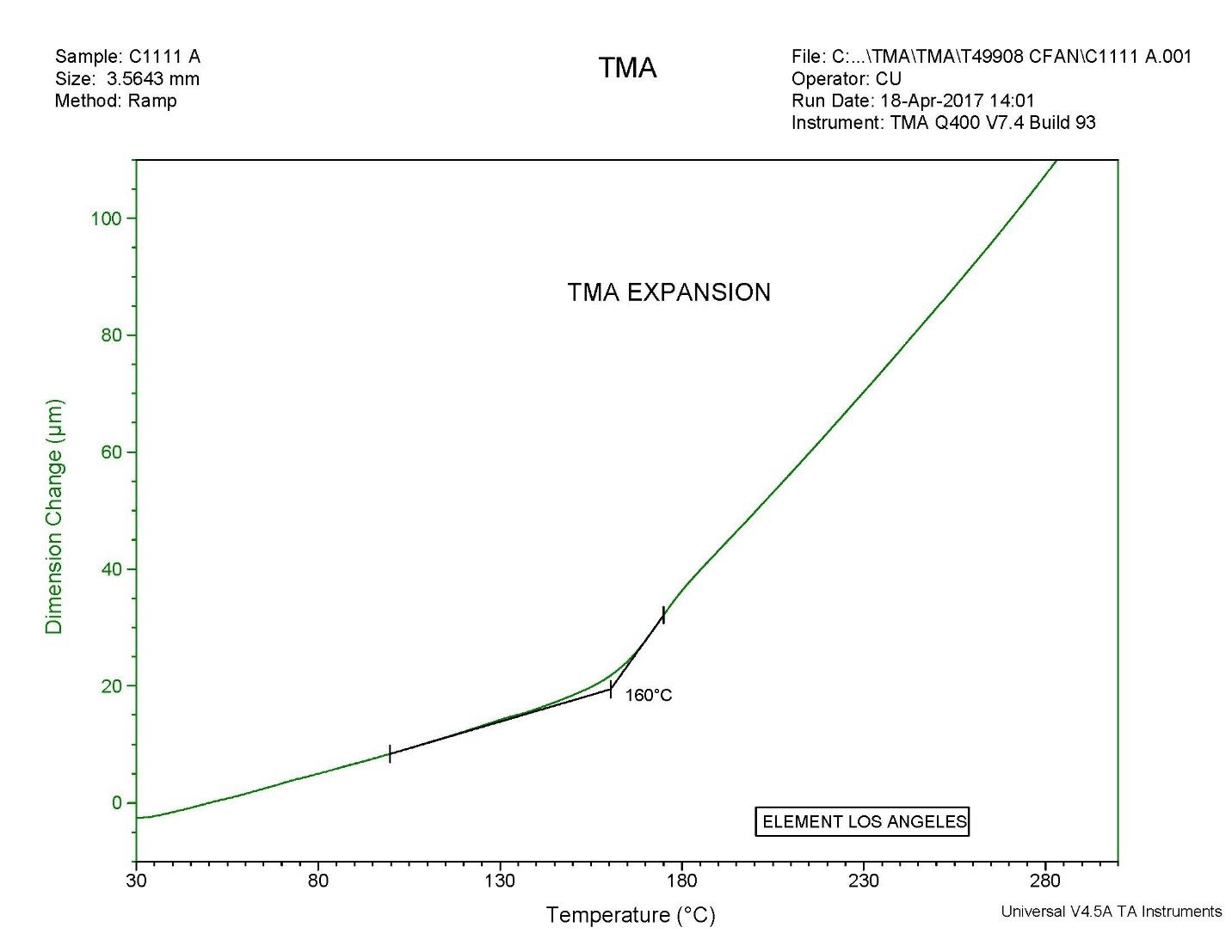

Thermomechanical Analysis (TMA): A thermomechanical analysis uses a small sample of material, which is heated on a quartz stage. A rod inside the machine places a small amount of force on the top of the sample, and the movement of the rod is measured with a linear variable differential transformer or LVDT. The entire instrument is heated at a slow rate, usually 5 degrees C per minute. This data is reported as a curve, where change in length is plotted versus temperature. The slope of the resulting curve is called the coefficient of linear thermal expansion, or COLTE. The glass transition temperature is the point at which the slope of the line changes, as seen below.

TMA may also be used in flexure or penetrations modes. In these approaches a larger force is applied until the probe deflects significantly.

Differential Scanning Calorimetry (DSC)

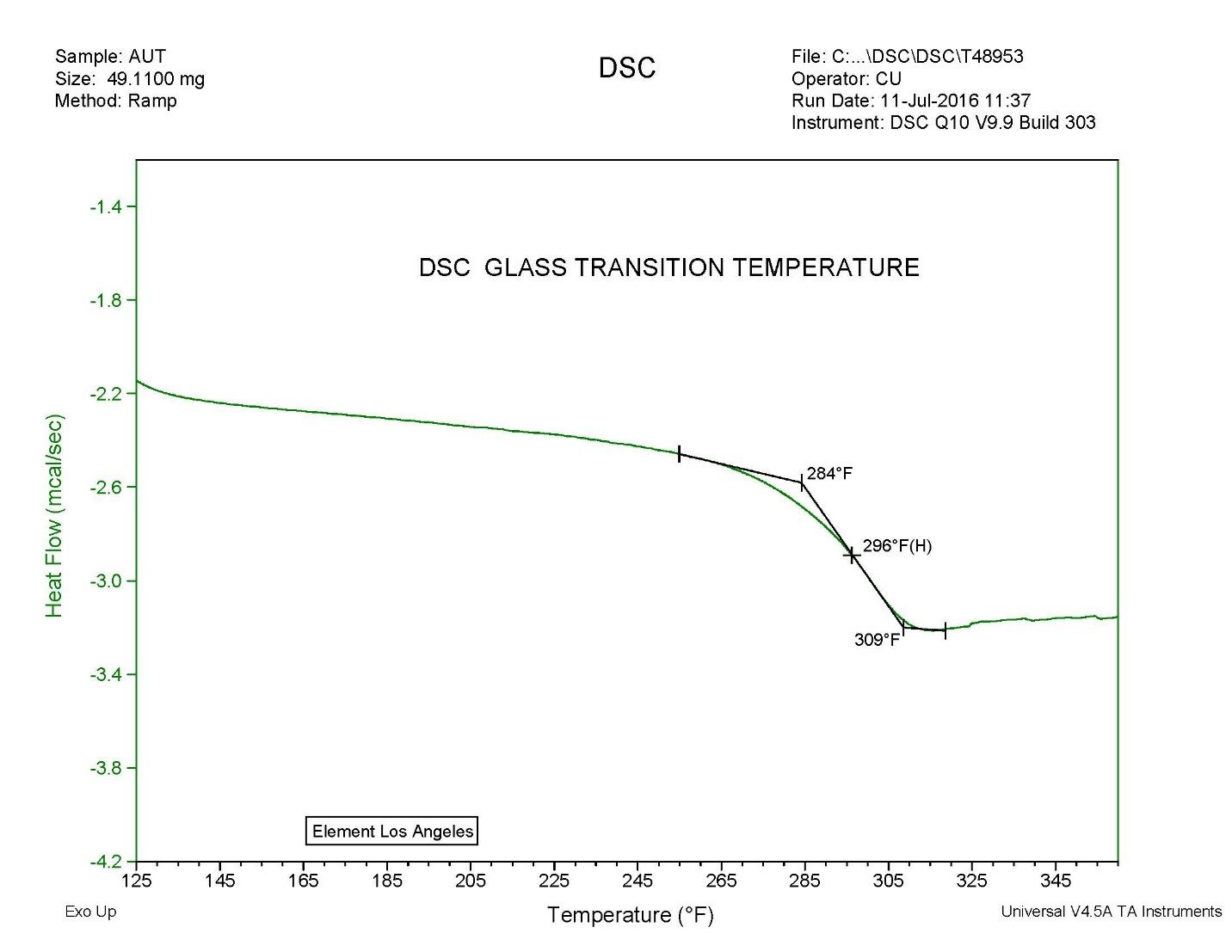

In the DSC test method, a small sample is heated while measuring the amount of energy required to heat the sample. This value is then compared to an inert reference material. Because the glass transition temperature will create a change in the properties of the material, the polymer chains reorient, requiring a change in energy to heat. This shows as an inflection on the curve. Three points may be selected and reported: the onset, which is the lowest value, the mid-point and end point.

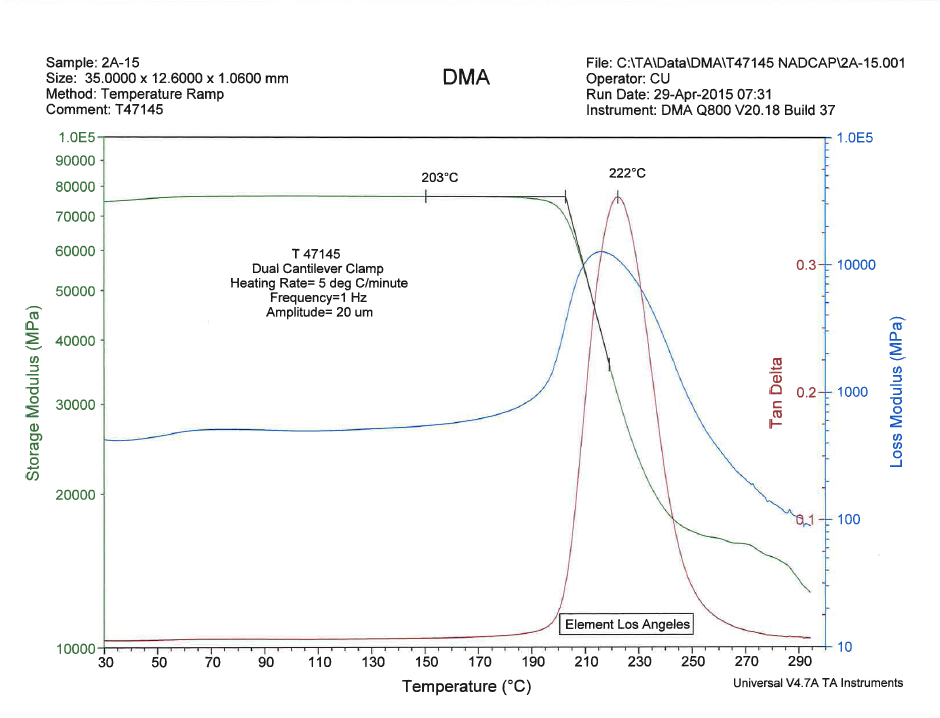

Dynamic Mechanical Analysis (DMA)

Element's expertise in glass transition temperature measurement

As evidenced above, glass transition temperature measurements can vary greatly in technique and calculation based on the specific material type, real world application, and many other factors. Element's polymer scientists have the knowledge and expertise required to support your material testing program and provide you with accurate and applicable data on your material.

Contact us today to learn more about our thermal analysis and analytical services offering.

Related Services

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Thermal Analysis Services

Element's thermal analysis services help identify material properties, anticipate changes, and reduce failure risks. Our experts provide accurate, reliable testing for polymers, composites, and advanced materials.

Thermomechanical Analysis (TMA)

Thermomechanical analysis (TMA) evaluates polymer thermal properties, including expansion and phase changes. Element provides precise data for R&D, quality control, and material classification.