Automotive Testing Services

From chassis to batteries, Element helps OEMs and suppliers bring automotive products to market faster with comprehensive automotive testing services. With 100+ years of expertise, cutting-edge simulation, and global testing, we reduce costs, speed up development, and ensure compliance across ICE, EV, HEV, and autonomous systems. Partner with us to deliver safer, high-performing, and reliable vehicles - quickly and efficiently.

Why Element are Global Leaders in Automotive Testing

As the automotive industry evolves - with electric vehicles (EVs), autonomous technologies, and stricter safety and emissions regulations - staying ahead demands more than innovation. You face complex supply chains, shorter product cycles, and intense pressure to deliver safe, reliable, and high-performing vehicles, fast.

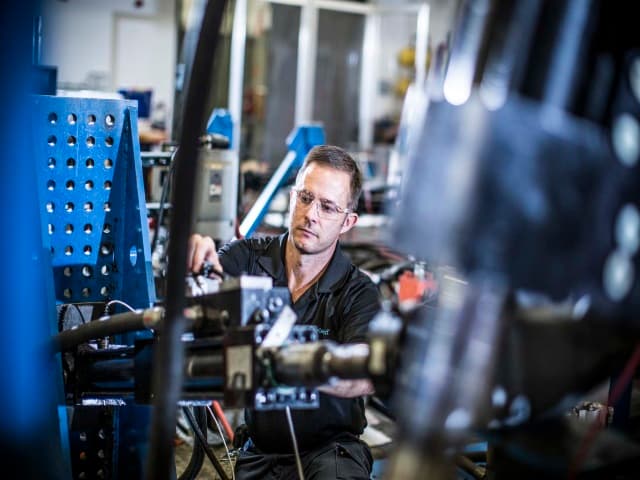

Element is your trusted global partner in automotive testing services, supporting OEMs and Tier 1 and 2 suppliers throughout the entire development journey, from early design validation to final compliance certification. With over 100 years of expertise, we test everything from EV batteries, motors, and powertrains to ICE systems, autonomous vehicle tech, and conventional chassis, suspension, and interior materials.

Our international team uses advanced simulation and testing methods to validate performance, durability, and safety across components, systems, and full vehicles. We also provide specialist fire testing through our group company Warringtonfire to meet rigorous interior material standards.

With Element, you gain more than accurate results - you gain a collaborative partner who helps you reduce development time, cut unnecessary costs without compromising quality, avoid service failures, and meet global regulations with confidence.

Services

Automotive Fire Testing

Accredited fire testing for automotive materials to verify flammability, burn resistance, and smoke behavior, ensuring compliance with ECE R118, FMVSS 302, ISO 3795, and OEM-specific safety standards.

Breath Alcohol Ignition Interlock Device (BAIID) Testing Services

We provide BAIID testing to verify compliance with global regulations. Our accurate and reliable testing ensures that breath alcohol ignition interlock devices perform safely and effectively in real-world conditions.

Automotive EMC Testing

Element provides comprehensive EMC testing services that simulate real-world scenarios to validate both whole vehicles and sub-assemblies, meeting international standards for safety and performance.

Multi-Axial Simulation Table (MAST) Testing Services

Element's MAST testing replicates real-world vibrations in a controlled lab, helping automotive engineers assess durability, reduce development time, and refine vehicle components for safer, more reliable performance.

Vehicle Fluid Systems Testing Services

Element offers comprehensive testing for automotive fluid systems, assessing durability and performance under extreme conditions to help manufacturers enhance reliability and meet industry standards.

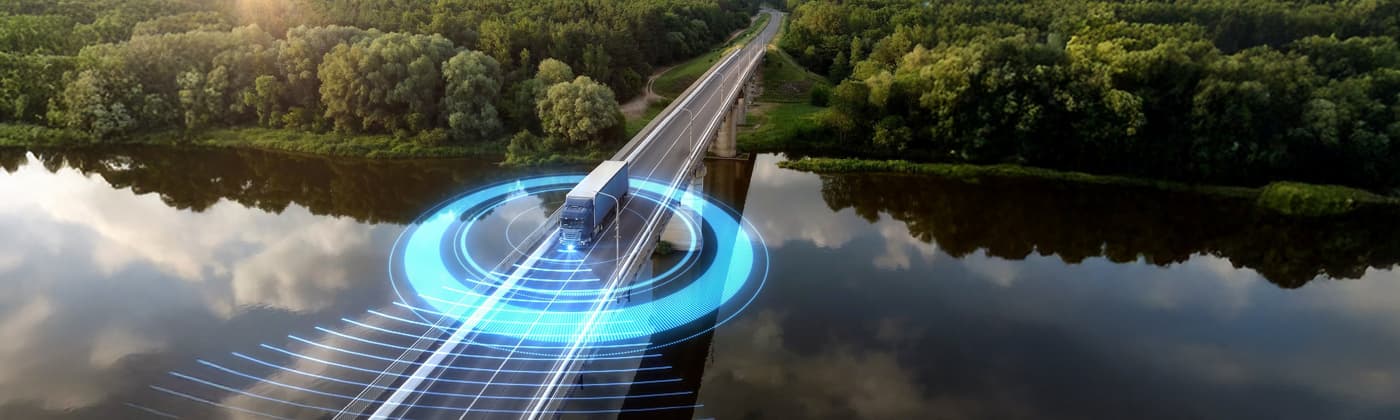

Advanced Driver Assistance System (ADAS) Testing

Element's ADAS testing services validate the safety and reliability of automated driving systems. With in-lab and field testing, we help manufacturers refine performance and bring trusted vehicle technology to market.

Airbag Deployment Testing

Element's airbag deployment testing delivers precise real-world simulations, helping manufacturers analyze timing, detect anomalies, and meet industry standards with high-speed video and advanced data acquisition.

Automotive Battery Testing

Element provides expert automotive battery testing to meet global safety and compliance standards. We test Li-ion and Ni-MH batteries for durability, performance, and regulatory approval.

Automotive Buzz, Squeak, and Rattle (BSR) Testing

Element's BSR testing identifies and eliminates unwanted vehicle noise, improving customer satisfaction and reducing warranty claims. Our advanced testing technology simulates real-world conditions for accurate, reliable results.

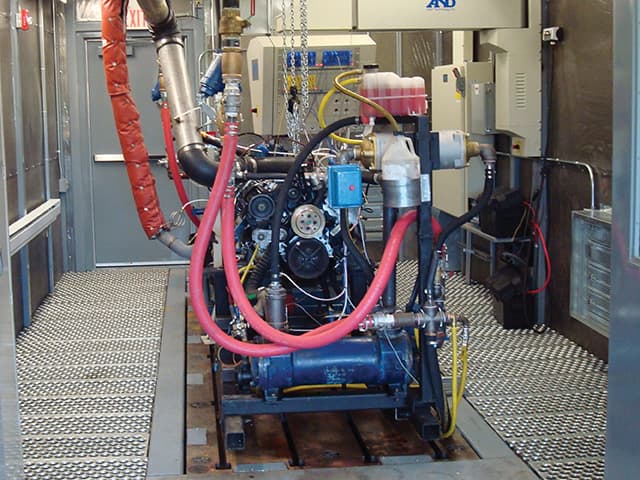

Automotive Dynamometer Testing Services

Gauge the performance and durability of your automotive drivetrain components with dynamometer testing from Element, the industry's most trusted third-party testing partner.

Automotive Product Testing

Element provides automotive product testing for durability, safety, and regulatory compliance. Our expert services help manufacturers validate vehicle components, streamline testing, and bring products to market with confidence.

Automotive Weathering Testing

Element's automotive weathering testing evaluates material durability against heat, moisture, and UV exposure, helping manufacturers prevent degradation, extend product lifespan, and meet industry standards.

Autonomous Vehicle Testing

Autonomous vehicle testing services to validate embedded systems, safety, and compliance. Partner with Element to bring your AVs to market with confidence.

Bending Stress and Flexural Strength Rail Testing

Element provides bending stress and fatigue testing for railroads, helping engineers validate materials, improve weld integrity, and prevent failures with advanced flexural and cyclic fatigue analysis.

Chassis and Suspension Testing

Expert chassis and suspension testing to accelerate your development timeline. Element delivers technical insights and custom solutions to ensure stronger, safer designs that outperform your competition.

Durability Testing of Trailer Hitches

Element provides expert durability testing for trailer hitches and towing equipment, evaluating strength, performance, and compliance to help manufacturers meet industry standards and improve product reliability.

Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

Accelerate your EV and HEV innovations with Element's comprehensive testing and certification services. Combining automotive heritage with specialized EV expertise, we ensure your components meet safety standards and market demands—faster and with confidence.

Electronic Component Testing Services

Element provides electronic component testing to help manufacturers verify PCB reliability, prevent failures, and meet compliance standards. Advanced testing solutions support automotive electronics development and production.

Engine and Powertrain Testing

Element provides advanced engine and powertrain testing to verify durability, performance, and compliance. From road simulations to materials analysis, we help automotive manufacturers develop reliable and efficient propulsion systems.

Vehicle Fluid Systems Testing Services

Element offers comprehensive testing for automotive fluid systems, assessing durability and performance under extreme conditions to help manufacturers enhance reliability and meet industry standards.

Fuel Components Testing

Element provides comprehensive fuel components testing for automotive and military applications, helping manufacturers validate safety, durability, and compliance to industry standards, reducing risks and costly recalls.

Full Vehicle Durability Testing

Element offers full vehicle durability testing, simulating real-world conditions in a lab to detect defects early, improve reliability, and support manufacturers in developing safer, long-lasting vehicles.

Road Load Data Acquisition & Analysis

Element's road load data acquisition and analysis services help optimize vehicle components by providing accurate performance data under real-world conditions, ensuring durability, reliability, and compliance with industry standards.

Vehicle Safety Systems Testing

Element provides advanced vehicle safety systems testing to help manufacturers meet top safety standards. Our expert testing covers active and passive systems, ensuring safer vehicles for the market.

- Automotive Fire Testing

- Breath Alcohol Ignition Interlock Device (BAIID) Testing Services

- Automotive EMC Testing

- Multi-Axial Simulation Table (MAST) Testing Services

- Vehicle Fluid Systems Testing Services

- Advanced Driver Assistance System (ADAS) Testing

- Airbag Deployment Testing

- Automotive Battery Testing

- Automotive Buzz, Squeak, and Rattle (BSR) Testing

- Automotive Dynamometer Testing Services

- Automotive Product Testing

- Automotive Weathering Testing

- Autonomous Vehicle Testing

- Bending Stress and Flexural Strength Rail Testing

- Chassis and Suspension Testing

- Durability Testing of Trailer Hitches

- Electric (EV) & Hybrid-Electric (HEV) Vehicle Testing

- Electronic Component Testing Services

- Engine and Powertrain Testing

- Vehicle Fluid Systems Testing Services

- Fuel Components Testing

- Full Vehicle Durability Testing

- Road Load Data Acquisition & Analysis

- Vehicle Safety Systems Testing

Your challenges, our solutions

Regulatory compliance complexity

Accelerated development cycles

Winning the innovation race

Standards we test to and components we test

- UN 38.3 (Battery testing)

- UL 2580 (Battery testing)

- IEC 60095 (Battery testing)

- ECE R100 (Battery testing)

- Automotive EMC standards

- FMVSS standards

- ISO standards

- SAE standards

- Automotive OEM specifications

- ECE R118

- Batteries and electric vehicle components

- Chassis and suspension systems

- Internal Combustion Engine (ICE) and powertrain components

- Electric (EV) & Hybrid-Electric Vehicle (HEV) motor and powertrain systems

- Interior and exterior trims

- Safety systems and seat belts

- Fuel components and systems

- Electric Vehicle fluids and lubricants

- HVAC and fluid cooling systems

- Exhaust systems

- Steering systems

- Electronics and control units

- Vehicle interior materials

- Acoustic materials and systems for NVH/BSR evaluations

- Alternative fuel systems

Why Choose Element

Unmatched technical expertise

Comprehensive service portfolio

Advanced testing capabilities

Collaborative approach

100+ Years

300+Channel data

95%Humidity

-40°C to +85°CTemperature

But don't just take our word for it

See what others have to say about partnering with Element

Advanced Testing Facilities and Methodologies

Our state-of-the-art automotive testing facilities feature specialized equipment that few competitors can match:

- Drive-in semi-anechoic chambers and quiet rooms for precise acoustic testing

- Environmental 4-post simulators with sound treatment for BSR evaluations

- Multi-Axial Simulation Tables (MAST) systems for comprehensive durability testing

- Extensive data acquisition capabilities with 300+ channel systems

- Advanced testing methodologies including:

- Sinusoidal and random vibration testing

- Transient capture and field data replication

- Noise, Vibration, Harshness (NVH) problem solving

- Transfer path analysis and acoustic sensitivity testing

Element's global network spans North America, Europe, Asia, and beyond, with consistent methodologies and quality standards ensuring reliable results across locations. Our test systems accommodate vehicles from passenger cars to light trucks up to approximately 11,000 lb. GVW, supporting your global product development and market entry strategies.