Electromagnetic Compatibility (EMC) Testing & Electromagnetic Interference (EMI) Testing & Certification

Element is the proven leader in EMI and EMC testing, compliance, and certification. We provide accredited electromagnetic compatibility services, helping you to meet regulatory requirements, and improve the performance and safety of products and devices through our global laboratories. Our testing programs deliver a full range of certification and validation services to meet your unique testing needs - with EMC and EMI testing for a wide range of critical industries, delivered through some of the largest testing facilities in the US, UK, and Germany.

Why Element Are Global Leaders in EMC & EMI Testing

Electronic devices are increasingly complex and interconnected, creating significant electromagnetic compatibility challenges. Today's products must operate reliably in environments crowded with wireless devices, all generating potential interference. Meanwhile, regulatory requirements continue to evolve, with standards becoming more stringent as new technologies emerge.

What is EMC / EMI Testing?

Electromagnetic compatibility testing (EMC) and Electromegnetic Interference testing (EMI) measures your electronic equipment's ability to function properly without causing or experiencing electromagnetic disturbances. This evaluation helps prevent malfunctions, user dissatisfaction, and safety risks while meeting mandatory regulatory requirements across global markets. As products increasingly incorporate wireless capabilities and operate at higher frequencies, EMC / EMI testing becomes more complex yet even more essential.

Element’s network of industry-leading global laboratories deliver a full range of certification and validation services tailored to your unique testing needs. We provide EMC and EMI testing for medical devices, automotive systems, aerospace equipment, consumer electronics, multimedia products, industrial equipment, and commercial electronics.

EMC and EMI testing methods

Our EMI and EMC functional testing capabilities include:

- Radiated and magnetic susceptibility

- Radiated and conducted emissions

- Radiated Immunity

- EMC RF Emission

- Electrostatic Discharge (ESD)

- EMI/EMC Shielding Effectiveness

- EMC compliance testing

- EMC pre-compliance testing

- FCC compliance testing

- Lightning testing

Additional compliance capabilities

Beyond standard EMC testing, we also provide testing to support the following regulatory requirements:

- Low Voltage Directive testing

- Machinery Safety Directive

- IEC/EN 61010-1 safety standards

Certifications we can help you to obtain

- CE marking for EU

- FCC certification for the US market & ISED certification for the Canadian market

- MIC certification for the Japanese market

- Global market approvals for international access to local markets

Services

Aerospace EMI/EMC Testing

Element's aerospace EMI/EMC testing helps you meet commercial and military standards with tailored test plans, advanced facilities, and expert guidance to tackle compliance challenges and reduce delays.

Automotive EMC Testing

Element provides comprehensive EMC testing services that simulate real-world scenarios to validate both whole vehicles and sub-assemblies, meeting international standards for safety and performance.

Medical Device EMC Testing

Element provides EMC testing and certification for Class I-III medical devices, helping manufacturers meet global regulatory standards and accelerate market entry with expert guidance and accredited laboratories.

MIL-STD-461 Testing Services

Access accredited MIL-STD-461 testing with secure ITAR handling at our specialized military EMC testing facilities. Our MIL-STD-461G testing validates defense systems up to 70 tons with 200V/m capability.

EN 50121 Railway EMC Standards

Element provides EMC testing and certification services for railway components, helping manufacturers meet EN 50121 standards for compliance, reliability, and safety in real-world rail environments.

Wireless Device Testing & Certification

Get your wireless devices to market faster with Element's accredited testing services. Expert guidance through compliance, certification and global approvals for all wireless technologies.

Your Challenges, Our Solutions

Complex global regulations

Costly redesigns and delays

Navigating certification processes

Standards we meet and the products we test

IEC and EN Standards

- ISO/IEC 17025

- European EMC Directive 2014/30/EU

- IEC/EN61000-4-x series

- IEC/EN61000-6-x series

- IEC/EN61000-3-2&3

- IEC/EN61326-x series

- IEC/EN55022/32

- IEC/EN55011

- IEC/EN55024/35

- IEC/EN50121-x series

- EN301 489-x series

- IEC/EN60601 series

- IEC/EN60945

- IEC/EN62368-1

- EN55032/CISPR 32 – Emission requirements

- EN55035/CISPR 35 – Immunity requirements

CISPR Standards

- CISPR 11

- CISPR 12

- CISPR 14-1

- CISPR 14-2

- CISPR 15

- CISPR 24/35

- CISPR 25

- CISPR 22/32

- EN55032/CISPR 32 – Emission requirements

- EN55035/CISPR 35 – Immunity requirements

Other Standards

- RTCA/DO-160 (aerospace)

- MIL-STD-461 (military/defense)

- FCC CFR47 part 15 and 18

- ICES-003

- GR-1089-CORE

- International IECEE CB scheme

Medical devices

- Class I electronic medical devices

- Class II electronic medical devices

- Class III electronic medical devices

Automotive

- Electronic components

- Systems and sub-assemblies

- Electric vehicle components

- E/e-marking on sub-assemblies and whole vehicles

- Agricultural equipment

Aerospace

- Civil aircraft electronic systems

- Aerospace electronic components

Military and defense

- Defense electronic systems

- Military-grade equipment

Multimedia equipment

- Audio equipment

- Video equipment

- Audio-visual (AV) equipment

- Sound and television broadcast receiver equipment

- Satellite broadcast and cable transmission equipment

- Entertainment lighting control equipment

- Information Technology Equipment (ITE)

Commercial & Consumer electronic products

- IT and office equipment

- Telecommunications equipment

- Radio communications equipment

- Laboratory, test and measurement equipment

- Control equipment

- Railway equipment

- Marine equipment

- Consumer electronics

- Wearable technologies

- Implantable devices

- Large capital items

- In-situ installations

- In-situ installations and equipment for computation and assemblies

Is EMC testing mandatory?

It is essential to test your products to ensure they meet the regulatory requirements; EMC certification is a mandatory requirement for a number of global markets. In addition to product safety and wireless coexistence, considering EMC principles in the early stages of the product development cycle will help to improve performance, reduce the risk of redesign, and mitigate unnecessary costs.

Why Choose Element

Global testing network

Complete testing solutions

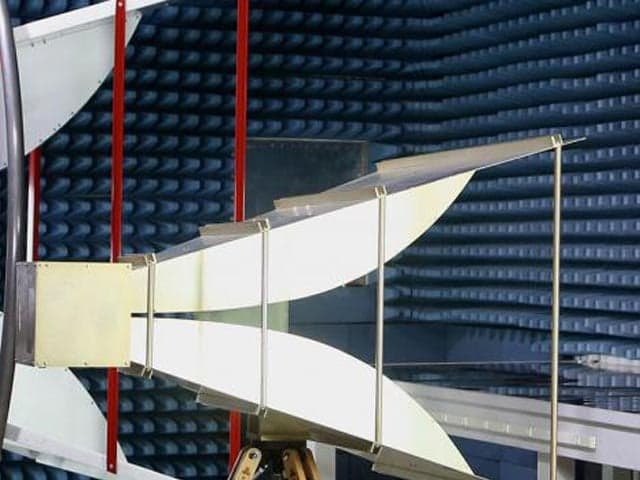

Specialized test chambers

Adaptive testing approaches

30+years

200+countries

5specialized chamber types

10+industries

But don't just take our word for it

See what others have to say about partnering with Element