Rapid Gas Decompression (RGD) Testing

Protect your critical equipment from seal failures with industry-leading RGD testing, including our groundbreaking hydrogen sulfide testing capability—available for the first time in the industry. Our innovative methods deliver unprecedented insights into material performance under real-world conditions, helping you validate components and prevent costly failures in high-pressure gas environments.

What is Rapid Gas Decompression Testing at Element?

Rapid Gas Decompression (RGD) has been a misunderstood phenomenon—until now. It occurs when gases seep into materials under pressure and cause damage during sudden pressure release. When pressurized, gases penetrate elastomeric seals and remain until pressure drops, causing the dissolved gas to escape and often resulting in ruptures and component failures. Staying at the forefront of Energy industry developments, Element evaluates how materials behave under these conditions using hydrogen sulfide (H2S), hydrogen (H2), carbon dioxide (CO2), and supercritical CO2.

What Can Element Offer You For RGD Testing?

Key tests offered

Key tests offered

Element conducts extensive cyclic pressure testing under High Temperature/High Pressure (HT/HP) conditions using multiple gas types, including our innovative hydrogen sulfide testing capability. Our comprehensive testing program evaluates:

- Material behavior under pressure cycling

- Deterioration patterns in sour gas environments

- Comparative performance in different gas types

- Failure modes under rapid decompression

- Long-term material stability

Innovative sour gas testing

Previously, RGD testing had only been performed using carbon dioxide and/or methane gases. While valuable, these methods didn't provide a complete picture. Element has developed a groundbreaking procedure for testing O-rings with hydrogen sulfide (H2S), a highly corrosive gas that provides a more accurate simulation of real-world conditions. This significant upgrade allows the sector access to RGD testing in sour environments for the first time, enabling direct comparison between sour and non-sour gas effects.

Materials and components we test

Materials and components we test

Our specialized facilities test a comprehensive range of elastomeric seals and non-metallic components used in high-pressure gas environments. We focus on critical components where seal integrity is essential for operational safety and equipment protection. Our testing capabilities cover:

- Various elastomeric seal types and sizes

- O-rings for different pressure applications

- Non-metallic components for gas environments

- Polymeric materials under development

- Critical sealing components for energy sector equipment

Methods and solutions offered

Methods and solutions offered

Our advanced testing procedures include controlled pressure cycling, sophisticated gas exposure methods, and detailed material analysis. We've developed specialized protocols for handling toxic gases like H2S, ensuring accurate simulation of aggressive service environments while maintaining strict safety standards. Our methods include:

- Precise pressure cycle control

- Multiple gas exposure scenarios

- Detailed material behavior analysis

- Comprehensive performance evaluation

- Safety-focused testing protocols

Our advanced RGD testing method

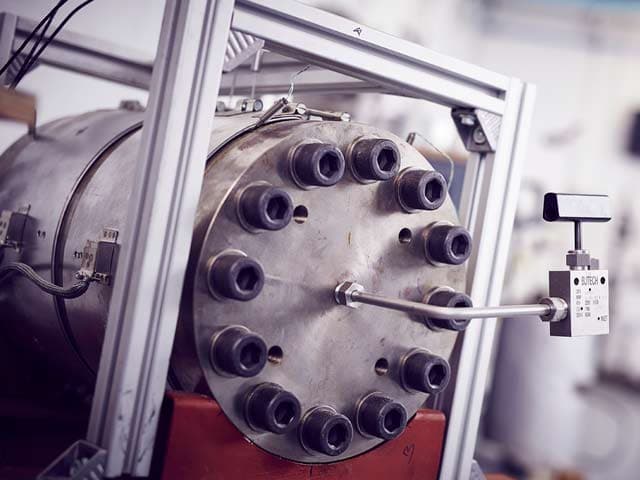

The RGD test is conducted by applying cyclic pressure inside a pressure vessel at High Temperature/High Pressure (HT/HP) conditions as is standard procedure but with stringent H&S additions as required for this highly toxic gas. This method subjects seals to both H₂S and a control (non-sour) gas to evaluate how sour gases affect the resistance to rapid gas decompression.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our facilities feature state-of-the-art pressure vessels capable of maintaining precise HT/HP conditions throughout testing cycles. We utilize specialized equipment for safe handling of corrosive gases, particularly in our groundbreaking H2S testing procedures. Our equipment enables:

- Accurate pressure control

- Safe toxic gas handling

- Precise temperature management

- Detailed performance monitoring

- Comprehensive data collection

Which labs offer this service

Which labs offer this service

Our team operates from Energy hubs across the world, providing global access to our expert capabilities. Find your nearest Energy hub on our Locations Page.

Materials and components we test

- Elastomeric seals and O-rings for high-pressure applications

- Non-metallic components exposed to gas environments

- Polymeric materials used in pressure-cycling conditions

- Critical sealing components for energy sector equipment

- Pressure-resistant materials for gas service

Your Challenges, Our Solutions

Real-world performance validation made possible

Advanced sour gas testing delivers certainty

Complete seal integrity assurance

Maximized equipment protection

Why Choose Element

Industry pioneer

Advanced testing capabilities

Comprehensive analysis

Safety-first approach

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Hydrogen Testing

Element performs hydrogen testing, including hydrogen piping system and pipeline testing according to ASME B31.12, the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.

Oil and Gas Testing

Element offers a wide range of Oil & Gas testing services, including mechanical and NDT testing, structural and corrosion testing, and failure analysis. Learn more.

Liquid and Gas Permeation Testing Services

Element's liquid and gas permeation testing services evaluate seals, o-rings, and other polymer component to highly corrosive oil and gas environments.