On-Site EPR Measurements - DoS Testing Services

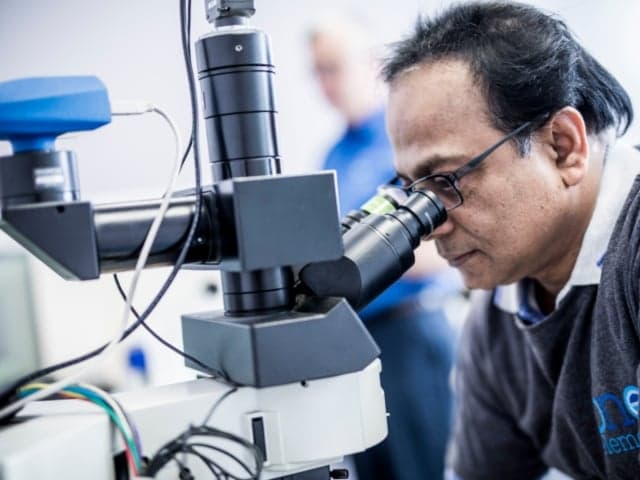

Non-destructive sensitization testing that doesn't slow down your operations. Element's on-site EPR measurements and DoS testing deliver faster, more accurate results right at your facility. Avoid costly downtime and get comprehensive sensitization analysis for your austenitic stainless steel equipment without the wait for laboratory results. Our proven DL-EPR testing methodology combines speed with precision for chemical and petrochemical facilities.

What is On-Site EPR Measurements - DoS Testing Services at Element?

On-site EPR measurements and DoS testing evaluate the degree of sensitization in materials using non-destructive methods. At Element, we utilize the Double Loop Electrochemical Potentiokinetic Reactivation (DL-EPR) test method to assess susceptibility to intergranular corrosion and polythionic acid stress corrosion cracking. Our testing is performed directly at your facility, providing rapid results without material destruction.

What Can Element Offer You For On-Site EPR Measurements - DoS Testing Services?

Components and materials we test

Components and materials we test

Element's specialized testing capabilities focus on austenitic stainless steels and alloys used in chemical and petrochemical industries. We assess components vulnerable to intergranular corrosion and polythionic acid stress corrosion cracking, ensuring your critical equipment maintains its integrity.

Key tests offered

Key tests offered

- Non-destructive DL-EPR testing

- Replica examination testing

- Grain size determination

- Quantitative DoS value assessment

- Qualitative precipitation analysis

- Surface preparation evaluation

Methods and solutions offered

Methods and solutions offered

We employ advanced polarization scanning from -500mV to 500mV with immediate reversal, measuring both activation and reactivation cycle current densities. Our comprehensive approach combines DoS testing with replica examination for complete material condition assessment, delivering both quantitative and qualitative results.

Cutting-edge equipment we use

Cutting-edge equipment we use

- State-of-the-art portable EPR testing equipment

- Specialized surface preparation tools

- Advanced polarization scanning technology

- Custom-designed test tubes for surface attachment

- High-precision measurement instruments

Components and materials we test

- Austenitic stainless steels

- Chemical processing equipment

- Petrochemical infrastructure

- Industrial-grade austenitic alloys

- Process equipment components

Your Challenges, Our Solutions

Destructive testing limitations

Time-critical results needed

Accuracy concerns

Risk of corrosion failure

Why Choose Element

Field-ready expertise

Edge-effect management

Dual analysis approach

Custom acceptance standards

Frequently asked questions

How does grain size affect DoS testing results?

Grain size significantly influences DoS measurements. We conduct replica examination testing to determine grain size and correct results accordingly, ensuring accurate assessment of material condition.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Energy Testing Services

Element provides expert testing to ensure energy materials are safe, reliable, and compliant, supporting both traditional and renewable energy sectors with comprehensive testing solutions.

In-Situ Replication Metallography and Replica Testing

Prevent equipment failures with Element's in-situ replication metallography - non-destructive testing that assesses material conditions while your operations continue. Expert analysis for high-temperature equipment. Request testing today

Corrosion Testing Services

Learn about our range of ISO/IEC 17025-accredited corrosion testing services. Safeguard your assets, ensure reliability, qualify welds, assess materials and enhance safety.

Metallurgical Testing Services

Expert metallurgical testing services to verify material integrity and prevent failures. Our accredited laboratories deliver precise analysis of metal microstructures, properties, and defects with expedited options. Ensure product reliability and compliance with industry standards.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.