Melt Flow Rate Testing

Gain fast, reliable insights into your thermoplastic materials with ASTM D1238 melt flow rate testing. Our testing supports quality control, product development, and failure investigations, helping you predict polymer behavior under various conditions. Element’s polymer experts offer hands-on guidance to ensure your materials meet performance and compliance standards.

What is Melt Flow Rate Testing at Element?

Melt flow rate testing measures how molten thermoplastic resins flow under specified conditions. It is widely used in quality control, material comparison, and failure analysis to evaluate polymer behavior. At Element, we evaluate material viscosity using extrusion plastometers to determine flow characteristics at defined temperatures and shear stresses.

What Can Element Offer You For Melt Flow Rate Testing?

Key tests offered

Key tests offered

We perform both Procedure A and Procedure B testing under ASTM D1238 to determine Melt Flow Rate (MFR) and Melt Volume Rate (MVR). Our comprehensive testing evaluates material viscosity, thermal stability, and molecular weight characteristics for quality control and product development applications. Testing capabilities include:

- Full melt viscosity analysis

- Standardized die extrusion evaluation

- Thermal stability assessment

- Molecular weight comparison studies

Materials we test

Materials we test

We test amorphous and semi-crystalline polymers, offering comprehensive analysis for materials requiring specific moisture level preparation and those ready for immediate testing. Our capabilities encompass both dried and as-received polymer testing, with specialized expertise in:

- Nylon and polyester materials requiring precise moisture control

- Polycarbonate and other amorphous polymers

- Polyolefin polymers requiring no prior treatment

- Various thermoplastic resins with specific handling requirements

Methods and solutions offered

Methods and solutions offered

Our testing process combines precise temperature control and standardized die extrusion using weighted pistons to deliver accurate, reliable results. A thermoplastic sample is heated in a barrel at a specified temperature, melted to a viscous fluid, and extruded through a standardized die under controlled weight. The extruded sample is then measured by weight or volume to determine material flow properties. We employ specialized preparation techniques for moisture-sensitive materials and conduct detailed analysis of flow characteristics under varied conditions. Our methodology includes:

- Controlled heating and melting processes

- Standardized die extrusion procedures

- Precise weight measurements

- Detailed viscosity analysis

Quality control expertise

Quality control expertise

Our specialized polymer testing capabilities support both quality control verification and product development applications. We help you validate material consistency, compare new materials, and make informed decisions about polymer performance in various applications.

Standards we test to and materials we test

- ASTM D1238

Amorphous polymers

- Polycarbonate

- Thermoplastic resins

Semi-crystalline polymers

- Nylon

- Polyester

- Polyolefin polymers

Your Challenges, Our Solutions

Need for reliable quality verification

Comparing and selecting reliable materials

Identifying and mitigating failure risks

Controlling moisture sensitivity

Why Choose Element

Industry-leading expertise

Comprehensive testing solutions

Standardized procedures

Global testing network

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Energy Coatings Testing Services

Protect your critical energy assets with Element's specialized coatings testing. We simulate extreme offshore and pipeline conditions to validate performance, prevent costly failures, and ensure compliance. Learn More.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Failure Analysis Services

Need expert Failure Analysis Services? Identify root causes fast with Element's advanced testing, global reach, and rapid turnaround. Get expert insights today.

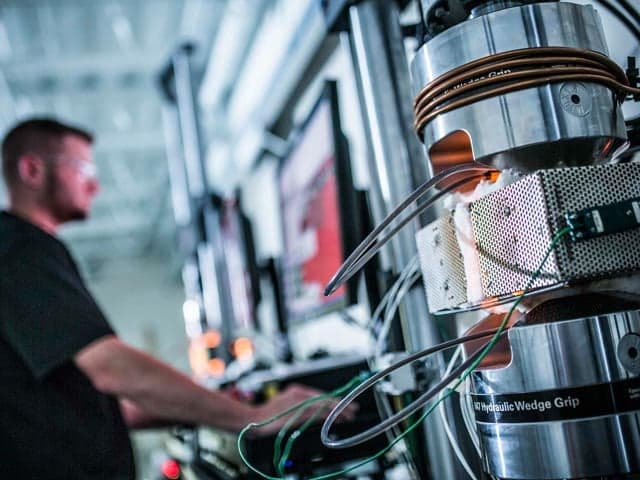

Mechanical Testing of Polymers

Element provides precise mechanical testing of polymers, delivering critical data on strength, resistance, and durability. Our expert analysis helps industries optimize material performance and maintain compliance.