3A Sanitary Testing for Dairy Contact Surfaces

Accelerate approval for dairy contact materials with Element’s fully accredited 3A Sanitary Testing. Our laboratories deliver first-time-right, on-time results for plastic and rubber materials used in dairy processing equipment, supported by hands-on technical experts and advanced instrumentation. We help you maintain product safety, meet regulatory requirements, and reduce time to market.

What is 3A Sanitary Testing at Element?

3A sanitary testing evaluates multiple-use plastic and rubber materials used in dairy processing equipment to verify their safety and performance. Element provides accredited testing services to validate that your materials meet 3A Sanitary Standards for product contact and cleaning contact surfaces, ensuring they maintain essential functional properties and compatibility with cleaning and sanitizing agents under typical dairy processing conditions.

What Can Element Offer You For 3A Sanitary Testing?

Materials we test

Materials we test

Elements' testing capabilities cover all plastic and rubber materials used in dairy processing equipment, including product contact surfaces and cleaning contact surfaces. We evaluate materials under accelerated use conditions to simulate real-world dairy processing environments, focusing specifically on materials used in the production, processing, and packaging of milk and milk-based products.

- Multiple-use plastic materials for dairy contact surfaces

- Rubber and rubber-like materials used in dairy equipment

- Food-grade gaskets, seals, and sealing components

- Materials used for liquid product handling

- Materials for cleaning system contact surfaces

- Heat-resistant materials for dairy applications

Key Tests Offered

Key Tests Offered

We perform comprehensive physical property testing, including heat aging, water absorption, and fluid exposure, to evaluate material performance in dairy processing conditions. These tests ensure materials withstand prolonged exposure to heat, moisture, and cleaning agents, which is crucial in high-performance dairy applications; all under conditions that simulate real-world wear and stress. Our testing services include:

- Heat aging of plastics without load (ASTM D3015)

- Water absorption analysis (ASTM D570)

- Durometer hardness Shore A and B measurements (ASTM D2240)

- Specific gravity testing (ASTM D792)

- Fluid exposure evaluation for rubber (ASTM D471)

Methods And Solutions Offered

Methods And Solutions Offered

Our testing approach combines accelerated use simulation with extensive materials analysis to evaluate physical properties and performance characteristics, simulating long-term use in dairy environments to ensure continued safety and compliance under rigorous operational conditions. We deliver accurate, first-time-right data that demonstrates compliance with 3A Sanitary Standards. Our comprehensive testing helps maintain essential functional properties throughout typical dairy processing operations, validating long-term performance.

Which Labs Offer This Service

Which Labs Offer This Service

Element New Berlin offers specialized capabilities for 3A testing. Our 8,500-strong team operates from labs across the world, providing global access to our expert capabilities. Find your nearest lab on our Locations Page.

Technical expertise

Technical expertise

Our technical experts specialize in chemistry, mechanical properties, and thermal analysis testing services, providing deep insight into how materials perform under thermal, chemical, and mechanical stress in dairy-specific applications.

Standards we test to and materials we test

Element performs sanitary testing to meet the material and serviceability requirements of:

- 3A Sanitary Standard method 18 for multiple-use rubber and rubber-like materials used as product contact surfaces in dairy equipment

- 3A Sanitary Standard method 20 for multiple-use plastic materials used as product contact surfaces.

- Multiple-use plastic materials for product contact surfaces

- Rubber and rubber-like materials for dairy equipment

- Food-grade gaskets and seals

- Contact surface materials for processing equipment

- Cleaning system materials

- Heat-resistant materials for dairy applications

Your Challenges, Our Solutions

Standards compliance made simple

Material compatibility verified

Quality assurance streamlined

Safety requirements achieved

Why Choose Element

Independent & Accredited Testing

Comprehensive Solutions

First-Time-Right Results

Accelerated Evaluation

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Food Testing Services

ISO 17025 certified food testing with industry-leading turnaround times. Partner with Element for microbiology, nutrition, allergen and safety testing to accelerate your product launches while ensuring compliance.

Thermal Analysis Services

Element's thermal analysis services help identify material properties, anticipate changes, and reduce failure risks. Our experts provide accurate, reliable testing for polymers, composites, and advanced materials.

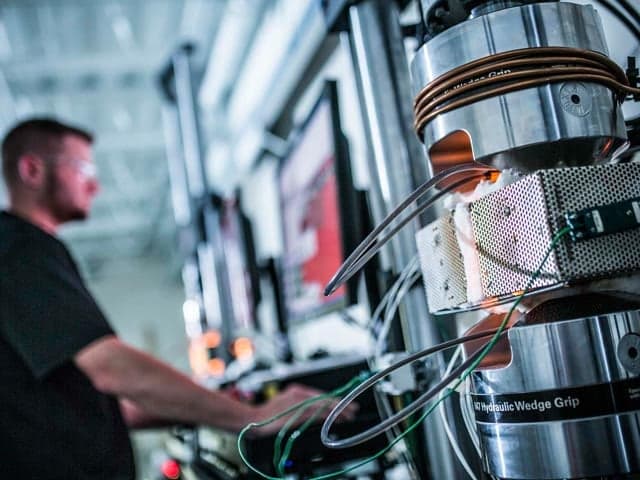

Mechanical Testing Services

Element provides fast, precise mechanical testing services for metals, polymers, and composites, helping industries meet compliance standards and optimize material performance with expert-driven assessments.

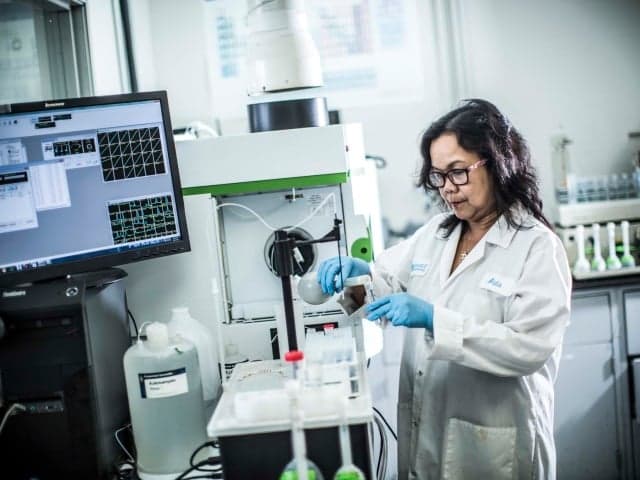

Chemical Analysis Services

Element’s chemical analysis services provide accurate material verification, compliance testing, and contamination detection. Our advanced methods deliver reliable insights for product development, quality control, and regulatory standards.