Precision Cleaning Services for Aerospace

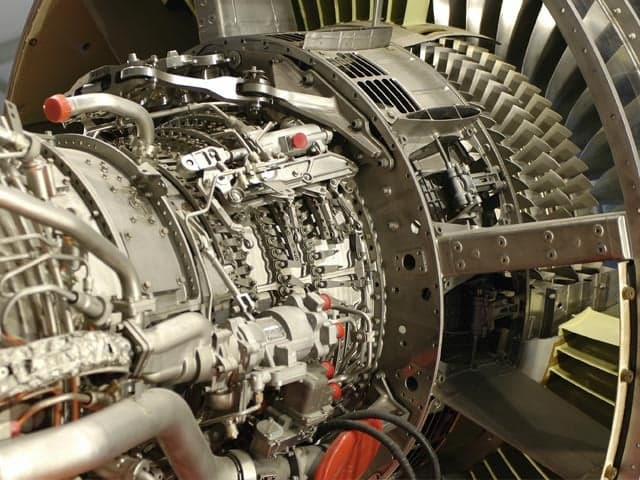

Partner with Element for end-to-end convenience and speed. We bring over 50 years of hands-on technical guidance. Elevate your mission-critical components to exceptional standards of cleanliness with specialized aerospace precision cleaning services. From ultra-high purity processing to advanced contamination control, ensure your components meet the most rigorous requirements for reliable performance.

What are Aerospace Precision Cleaning Services at Element?

Precision cleaning is the specialized process of removing contaminants from critical components to meet stringent cleanliness standards. At Element, we are a preferred precision cleaning supplier with nearly 190 years of combined heritage in testing and analysis. We deliver comprehensive precision cleaning services using advanced methods and controlled environments, ensuring that aerospace components exceed required specifications for mission-critical applications on almost any material.

What Can Element Offer You For Precision Cleaning?

What We Process

What We Process

We specialize in precision cleaning for mission-critical components where cleanliness is paramount. Our expertise spans hydraulic systems, oxygen-service components, and high-purity applications requiring exceptional standards:

- Hydraulic and lube oil systems

- Oxygen service components

- High-pressure systems

- Delicate surface components

- Critical aerospace parts

- Cryogenic equipment

- Precision manufacturing components

Key Tests Offered

Key Tests Offered

Our comprehensive testing capabilities ensure your components meet precise cleanliness specifications:

- Particle count analysis

- Non-Volatile Residue (NVR) analysis

- Visual inspection

- Pressure testing up to 50,000 psi

- Helium leak testing

Additional test and service capabilities include:

- Commercial oxygen cleaning

- Descaling and acid cleaning of iron and carbon steel

- Overhaul and repair services

- Total hydrocarbon analysis

- Gas sampling

- Verification of dryness

- Hardware assembly

- Sealing and specialized packaging

- Clean room rental

Our Precision Cleaning Expertise Includes:

- Cryogenic testing

- Pickle and passivation

- Deoxidation

- Etching

- Vacuum bake-out

- Ancillary specialized services

Methods and Solutions Offered

Methods and Solutions Offered

Cleaning Methods

- Aqueous cleaning

- Immersion cleaning

- Ultrasonic cleaning

- High-pressure spray cleaning

- CO2 cleaning

- Injection flooding

- Delicate surface wiping

- Vacuum bake-out

Aerospace Hydraulic Cleaning and Testing

- On-site, state-of-the-art service for hydraulic and lube oil systems and components

- Class 10,000 cleanroom specifications

- Proof pressure and leak testing to 50,000 psi (345,000 kPa) using DI (Deionized) water or hydraulic fluid

- Proof pressure and leak testing to 20,000 psi (138,000 kPa) using GN2

- Cleaned and tested hardware preserved in hydraulic fluid, then sealed or packaged in nitrogen-purged envelopes

Cleanliness Verification

- Visual inspection

- Particle count analysis

- Non-Volatile Residue (NVR) analysis

Cutting-edge Equipment We Use

Cutting-edge Equipment We Use

Our state-of-the-art facilities feature:

- ISO 14644-1 & -2 Class 7 and Class 5 Cleanrooms

- FED-STD-209 Class 10,000 and Class 100 Cleanrooms

- High-pressure testing equipment up to 50,000 psi

- Advanced contamination analysis equipment

- Specialized packaging systems

Which Labs Offer This Service

Which Labs Offer This Service

Our team operates from service hubs across the world, providing global access to our expert capabilities.

Visit our Locations Page to find your nearest hub.

End-to-end Support

End-to-end Support

We offer:

- Specialized packaging and preservation

- Hardware assembly services

- Clean room rental options

- On-site services

- Complete documentation and verification

Standards we test to and materials we test

- ISO 14644-1 & -2

- FED-STD-209

Environmental control is provided by ISO 14644-1 & -2 Class 7 and Class 5 Cleanrooms and FED-STD-209 Class 10,000 and Class 100 Cleanrooms.

Aerospace Components

- Hydraulic systems

- Lube oil systems

- Oxygen service components

Industrial Equipment

- High-pressure systems

- Cryogenic equipment

- Fluid power components

Specialized Applications

- Ultra-high purity components

- Precision manufacturing parts

- Critical system components

Your Challenges, Our Solutions

System failure risk

Meeting industry standards

Complex component requirements

Process validation demands

Why Choose Element

Proven industry experience

Comprehensive solutions

Advanced facilities

Flexible capabilities

50+years

50,000 psi testing capability

8+Specialized cleaning methods

190years of combined heritage

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace

Element are the largest global independent provider of aerospace testing services with over 100 years of experience and world-class testing, qualification, calibration, and advisory services.

Aerospace Product Qualification Testing (PQT) Services

Explore Element's aerospace product qualification testing (PQT) services. Ensure safety, compliance, and efficiency with our global expertise and accredited capabilities.

Aerospace Engine Testing Services

Element’s aerospace engine testing provides reliable testing under extreme conditions, helping you optimize performance, reduce risks, and meet deadlines. Learn more.

Avionics Systems Testing

Streamline your commercial, defense, and business/general avionics systems testing with Element's end-to-end aerospace testing solutions. Our expert engineers deliver critical EMC, environmental, and RF testing services across global labs. Learn More.

Chemical Etching Services

Element’s chemical etching services detect hidden defects, refine material surfaces, and prepare samples for advanced testing. Trusted for precise, non-destructive analysis - save time and cost by uncovering imperfections before NDT or mechanical testing.

Non-Destructive Testing (NDT) and Inspection Services

Get precise, reliable non-destructive testing (NDT) to detect flaws, verify material integrity, and meet industry standards, saving time and reducing risk. View services.