Welder Performance & Weld Procedure Qualification - WPQ, WPQR, & WPS

Accelerate your path to welding certification with comprehensive qualification testing that meets global standards. Our ISO 17025 accredited laboratories and certified welding inspectors provide end-to-end support from procedure development to final documentation, increasing field repair success while reducing costs and delays. Trust our technical expertise to streamline your compliance journey.

What is Welder Performance & Weld Procedure Qualification at Element?

Welding qualification testing validates both welding procedures and welder skills against international standards. At Element, as a recognized leader in welding services, we provide complete qualification services including procedure development, testing, certification documentation, and Notified Body endorsement through our ISO 17025 accredited laboratories that increase the chance of successful repairs in the field, limit the cost of delays, and save money.

What Can Element Offer You For Welder Performance & Weld Procedure Qualification?

Key tests offered

Key tests offered

We deliver full-scope qualification testing including destructive and non-destructive examination, mechanical property validation, and post-weld heat treatment verification. Our testing services include:

- Destructive testing for mechanical properties

- Non-destructive examination

- Post weld heat treatment verification

- Weld monitoring and data recording

- Qualification testing to multiple standards

Methods and solutions offered

Methods and solutions offered

Our qualification services provide complete support throughout your certification journey, from initial procedure development through final approval. We combine technical expertise with comprehensive documentation to streamline your qualification process. Our systematic approach includes preparation of detailed qualification records, monitoring of all test parameters, and compilation of complete certification packages.

Element offers testing for all aspects of weld procedure and performance qualification to help you achieve your welder certification by providing:

-

Qualified generic Weld Procedure Specification sheet (WPS)

-

Range of approval sheet, allowing visibility of procedural restrictions based on essential variables

-

Record of weld test sheet, showing all the key features used to qualify the procedure

-

Monitoring data, each and every run, as recorded by the weld inspector

-

Parent material certificates

-

Filler material certificates

-

Non-destructive testing reports

-

Destructive testing reports

-

Post weld heat treatment graph/report (if applicable)

-

Notified Body endorsement as required

For welders who pass their performance test and achieve certification, Element provides qualification documents, including:

-

Welder qualification test certificate

-

Prolongation continuation sheet

-

Laboratory test reports

-

Notified Body endorsement as required

Technical expertise and support

Our ASME and AWS-certified welding inspectors guide you through every step of qualification, combining their technical wealth of experience with specialized welding equipment to increase the chance of successful repairs in the field, limit costs of delays, and save money:

-

Procedure development consultation

-

Standards interpretation

-

Testing oversight

-

Documentation review

-

Certification support

-

Ongoing technical guidance

Preliminary or Proposed Weld Procedure Specification (pWPS)

Our welding experts can also help you develop new weld procedures that meet project requirements. We review client specifications against fabrication needs, prepare pWPS, and interpret testing and acceptance criteria. After customer feedback, we refine the procedure and finalize instructions for welders and inspectors once all parties agree.

Materials and components we test

Materials and components we test

Our ISO 17025 and AWS accredited laboratories perform comprehensive testing on welded components and materials to validate your welding procedures and welder skills. We evaluate samples through both destructive and non-destructive methods to verify weld integrity and performance across multiple standards and specifications. Our testing process includes detailed monitoring of each weld run, comprehensive documentation of test results, and thorough evaluation of material properties. Our testing capabilities cover:

- Welding plates and pipes for procedure qualification

- Parent materials with full certification

- Filler materials with complete documentation

- Test coupons for performance validation

- Heat-treated components with treatment verification

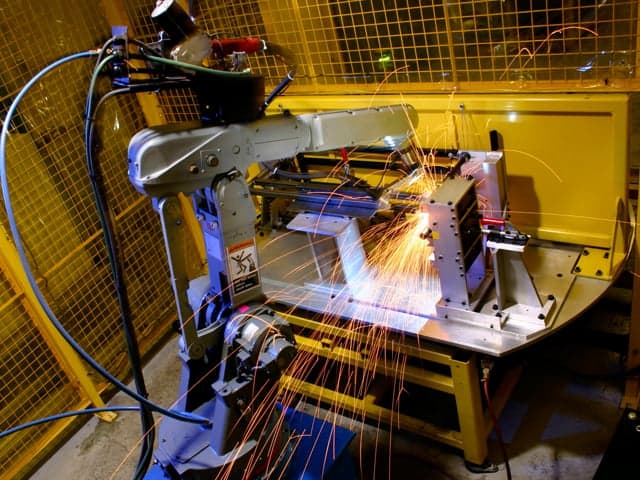

Cutting-edge equipment

Cutting-edge equipment

Our laboratories maintain specialized welding and testing equipment for comprehensive qualification programs, including:

- Advanced monitoring systems

- Destructive testing equipment

- Non-destructive testing capabilities

- Heat treatment facilities

- Data recording systems

Which labs offer this service

Which labs offer this service

Our team operates from Materials Testing Services hubs across the world, providing global access to our expert capabilities. Find your nearest Materials Testing Services hub on our Locations Page.

Standards we test to and materials we test

- ASME

- AWS

- API

- MIL-STD

- PED/EN

Welding materials

- Welding plates

- Welding pipes

- Test coupons

Base materials

- Parent materials

- Filler materials

Heat-treated components

- Post-weld treated materials

- Heat-affected zones

Your Challenges, Our Solutions

Navigating qualification process

Avoiding costly delays

Ensuring absolute conformance

Preparing documentation correctly

Why Choose Element

Global laboratory network

Complete qualification solutions

Technical excellence

Quality assurance

But don't just take our word for it

See what others want to say about ...

Frequently asked questions

What is a Welding Procedure Qualification Record (WPQR)?

A WPQR is a company-specific qualification that proves that the holding company possesses the technical welding knowledge necessary to perform metal joining work. Generally, a new welding procedure qualification record is required each time a welding procedure is introduced.

To obtain the qualification, an independent specialist must observe the new procedure being used on a sample welding plate or pipe. Element's experienced welding coordinators can support you in the process of creating welding procedure and are also authorized to act as independent specialists.

Once the sample welding plate or pipe has been welded, it is machined into test samples, which can then be passed to the Element laboratories for destructive and non-destructive testing. Element then presents the results of these tests in a certificate (the WPQR) which provides a practical assessment of the welding method description. All of this testing is conducted under ISO 17025 certification.

What is a Welder Qualification Certificate (WQC)?

A WQC is a test certificate that shows whether a welder is skilled in welding to the specifications of a particular standard. Element welding specialists can certify the welder through destructive and non-destructive tests to determine whether the welder is capable of producing a good weld quality using the welding processes, materials, and prescribed procedures.

A welder who has performed a test for a Welding Procedure Qualification Record (WPQR) automatically qualifies as a welder. If a good result is achieved, the welder receives an individual test certificate — the WQC.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Weld Fatigue Testing of Steel Catenary Risers

Element's full-scale pipeline fatigue testing facility uses state-of-the-art mobile testing containers to perform laboratory or on-site weld fatigue testing of steel catenary risers.

Oil & Gas Weld Testing Services

Element provides a comprehensive range of weld testing services to the Oil & Gas industry in compliance with international and national codes and standards.

Welding Fume Exposure Monitoring Services

Element's welding fume exposure monitoring service helps protect your workforce and ensure HSE compliance. We provide comprehensive air quality assessments, including fume analysis and LEV testing, to identify and control exposure risks. Our expert team delivers tailored solutions, including risk assessments and training, to create a safe and compliant welding environment.

Welding Services

Ensure weld integrity with Element’s expert welding engineering services, advanced NDT, and fast turnaround. Trusted globally for quality, compliance, and performance.

Weld Testing Methods

Element provides advanced weld testing services, including non-destructive and destructive methods, to verify weld integrity, meet industry standards, and prevent failures in critical applications.

Weld Inspection Services – CSWIP, PCN and CWI

Reduce component failures with Element's weld inspection services. Our CSWIP, PCN and CWI certified experts deliver comprehensive testing across all fabrication stages. Ensure quality compliance with trusted certification.