Thermal Shock Testing Services

Validate your products' durability with our liquid-to-liquid thermal shock testing that delivers superior temperature ramp rates between -65°C and +150°C. Our rapid transitions (under 10 seconds) identify potential failures faster than conventional methods, while custom specimen holders accommodate various product sizes. Meet industry standards while ensuring your products withstand real-world temperature extremes.

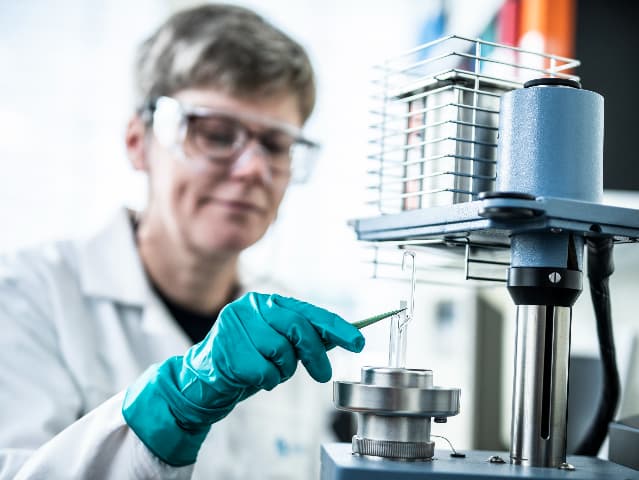

What is Thermal Shock Testing at Element?

Thermal shock testing evaluates product durability by rapidly cycling components between extreme temperatures. At Element, we specialize in liquid-to-liquid thermal shock testing, where a programmable mechanical transfer arm rapidly moves test specimens between hot and cold liquid reservoirs in under 10 seconds. This method offers superior temperature ramp rates and comprehensive testing capabilities from -65°C to +150°C to validate your products' thermal resilience.

What Can Element Offer You For Thermal Shock Testing Services?

Components and products we test

Components and products we test

Our comprehensive testing capabilities cover everything from delicate electronic components to robust aerospace assemblies. We specialize in testing multi-material products and bonded components where thermal expansion properties are critical. Our custom containment systems accommodate products of various sizes and geometries, ensuring accurate testing regardless of your product's specifications.

- Electronic systems and components

- Aerospace and defense hardware

- Transportation equipment

- Telecommunications devices

- Bonded material assemblies

Key tests offered

Key tests offered

We deliver industry-leading thermal shock testing through our advanced liquid-to-liquid systems. Our testing protocols simulate real-world conditions with unprecedented precision, helping you validate product durability and reliability. From standard compliance testing to custom thermal cycling programs, we provide comprehensive solutions tailored to your specific requirements.

Methods and solutions offered

Methods and solutions offered

Our liquid-to-liquid thermal shock systems consist of two reservoirs—one filled with a high-temperature liquid heat transfer medium and another with a low-temperature cold liquid. This innovative approach delivers superior results through rapid temperature transitions and precise control. The transfer typically occurs in under 10 seconds, subjecting your products to violent thermal shocks that far exceed what's possible with conventional air-to-air thermal chambers.

We offer various heat transfer liquid options depending on your application's temperature requirements and material compatibility factors, including:

- Water for less extreme temperatures

- Silicone oils for moderately high heat

- Specialized thermally stable inert liquids with high electrical resistance and low surface tension for extreme testing

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art thermal shock testing facilities feature dual-reservoir systems with advanced temperature control capabilities. The programmable mechanical transfer arms ensure precise, repeatable testing cycles, while our specialized containment systems protect your products during testing. Our equipment maintains strict temperature tolerances throughout the entire testing process.

- Advanced dual-reservoir systems

- High-precision temperature controllers

- Specialized heat transfer mediums

- Custom perforated specimen baskets for larger or oddly shaped test articles

- Automated cycling mechanisms

Which labs offer this service

Which labs offer this service

Our team operates from Product Qualification Testing hubs across the world, providing global access to our expert capabilities. Find out where your nearest Product Qualification Testing hub is on our Locations Page.

Standards we meet and the materials we test

Rigorous methodology complies with numerous industry test specifications and quality assurance standards such as:

- MIL-STD-810

- MIL-STD-202

- MIL-DTL-38999

- TIA/EIA guidelines, and more

- Electronic components and systems

- Aerospace components

- Defense equipment

- Transportation systems

- Telecommunications hardware

Your Challenges, Our Solutions

Protecting products in extreme environments

Meeting rigorous industry standards

Ensuring transport and storage durability

Validating material bond integrity

Why Choose Element

More extreme temperature transition capability

Comprehensive temperature range

Flexible testing solutions

Multiple medium options

-65°C to +150°Crang

<10seconds transfers

2reservoir

Frequently asked questions

How does liquid-to-liquid thermal shock testing work?

Our system uses two reservoirs—one with hot liquid and one with cold liquid. A programmable mechanical transfer arm rapidly moves your test samples between these reservoirs in under 10 seconds, creating violent thermal shocks that far exceed what's possible with conventional air-to-air chambers.

What types of failures can thermal shock testing identify?

Thermal shock testing can reveal design weaknesses that lead to shattering, binding, cracking, or internal damage—particularly in products with bonded materials that have mismatched thermal expansion properties. This helps ensure your products perform reliably in real-world conditions.

What types of failures can thermal shock testing identify?

Thermal shock testing can reveal design weaknesses that lead to shattering, binding, cracking, or internal damage—particularly in products with bonded materials that have mismatched thermal expansion properties. This helps ensure your products perform reliably in real-world conditions.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Thermal Conductivity Testing Services

Element provides thermal conductivity testing and measurement services, including R-value, to ensure your materials insulate, conduct, and withstand temperature changes. Expert thermal conductivity testing for aerospace, oil & gas, and transportation materials. ISO 17025-accredited, non-destructive methods ensure safety, compliance, and performance in extreme conditions

Thermogravimetric Analysis (TGA) Services

Element's thermogravimetric analysis (TGA) services help identify phase transitions, degradation reactions, and material composition, providing critical insights for research, development, and compliance across industries.

Thermomechanical Analysis (TMA)

Thermomechanical analysis (TMA) evaluates polymer thermal properties, including expansion and phase changes. Element provides precise data for R&D, quality control, and material classification.

Fracture Mechanics and Fracture Toughness Testing

Element provides fracture mechanics and fracture toughness testing services to evaluate material resistance, reduce repair costs, and optimize designs for safer, longer-lasting components across industries.

Thermal Vacuum Testing Services

NASA-recognized thermal vacuum chamber testing for space components. Simulate extreme environments with precision temperature cycling and high vacuum. Prevent costly failures before launch.