Lithium-ion batteries in e-bikes: Tackling the safety risk with testing

This article provides an overview of lithium-ion batteries used in electric bikes, focusing on safety standards and compliance requirements. It discusses the importance of adhering to safety protocols to prevent hazards associated with battery use and emphasizes the need for proper certification to ensure product reliability and consumer safety.

Across the world, lives are being lost, people injured, and property damaged, as a result of poorly designed and manufactured lithium-ion batteries in micro-mobility products such as e-bikes and e-scooters. In many countries, the lithium-ion batteries used in these products can go on sale with little or no formal safety testing.

Why are lithium-ion batteries used in micro-mobility products and what makes them dangerous?

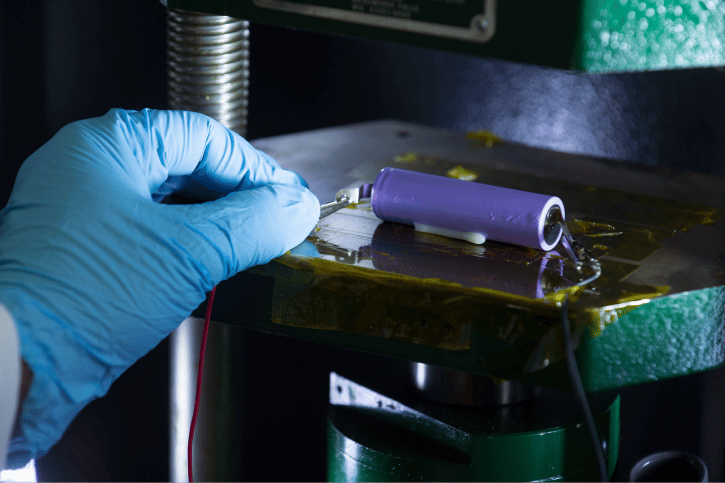

Lithium-ion batteries have high energy density, no memory effect, good cycle life, and low self-discharge. If subjected to improper handling, physical abuse, or improper charging, poor-quality lithium-ion batteries have a higher risk of going into thermal runaway, resulting in high heat, fire, explosion, shrapnel, and the venting of noxious gases.

If we are to see a reduction in incidents, all lithium-ion batteries used in micro-mobility products should be certified by an accredited third-party laboratory before being released into the global market.

Micro Mobility Devices - Key Components of the Energy System

What difference would accredited testing to accepted battery regulations make?

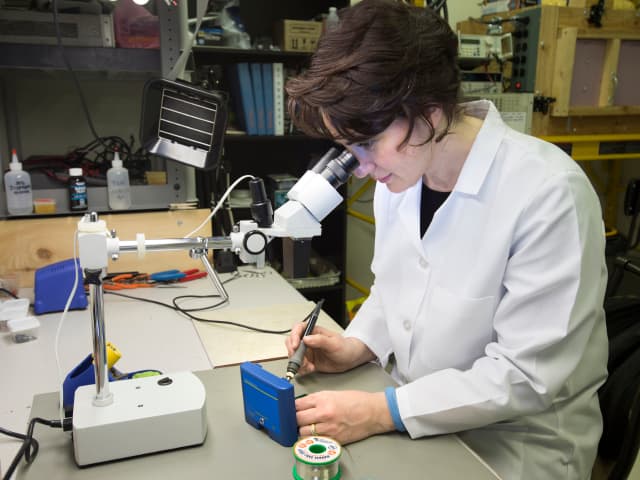

The implementation of regulations for lithium-ion batteries used in micro-mobility devices would provide a minimum safety threshold for both the design and manufacture of products. Proper product development practices should include design verification testing to confirm that the design meets specifications, and production validation testing to prove that the factory is capable of mass-producing a compliant product. Both testing types are precursors to any regulatory testing.

Regulatory testing is a final check before the product enters the market and should be based on accepted product safety standards, whether international, national, or industry-specific, and carried out by an unbiased third-party laboratory accredited to the standards being applied. Once a product passes testing it is ready for regulatory certification.

With certification, the product is labeled with a discernable and verifiable regulatory mark. The certifying agency also conducts periodic onsite follow-up services at the manufacturer to validate that the product is still being manufactured to the same standard to which it was originally approved.

Where Your Accredited Testing Partner Can Add Support & Value

How can I keep myself safe before proper regulation is introduced?

• Buy micro-mobility products from reputable manufacturers and dealers

• Be aware that the rule of “you get what you pay for” generally applies to battery products

• Look for a regulatory mark on the battery confirming that an accredited laboratory tested it before purchase

• Provide safe storage for micro-mobility products when not in use

• Do not charge micro-mobility products indoors

Remember, there is no substitute for proper design, high-quality components, and controlled manufacturing in the quest to have quality products in the marketplace. In the case of lithium-ion batteries intended to power micro-mobility devices, this is particularly critical given the amount of stored energy and the increased probability of poor-quality cells experiencing thermal runaway, risking bodily injury and/or property damage.

Related Services

Battery Safety Testing for Medical Devices

Battery safety testing for medical devices, assessing performance, reliability, and compliance with international standards to support safe use in healthcare settings.

Battery Performance Testing & Competitive Benchmark Testing

Element's battery performance testing and competitive benchmark testing delivers accurate, real-world data on capacity, endurance, and discharge rates to help refine products, reduce risk, and support competitive market positioning.

Battery Failure Analysis

Element's comprehensive cell and battery failure analysis identifies failure modes and the root cause of product failure, providing the insights you need to design superior products.

Battery Safety and Abuse Testing

Element delivers advanced battery safety and abuse testing for various chemistries and formats, helping identify risks, support certification, and meet global standards across diverse industries and applications.