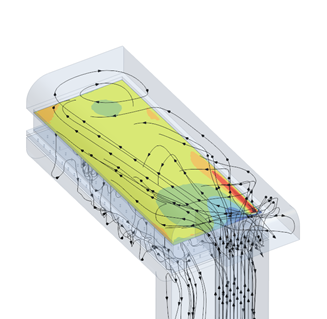

Hydrogen fuel cell design analysis to optimize flow paths within the cell core

This case study outlines how Element's Digital Engineering team, led by Tom Elson, utilized Computational Fluid Dynamics (CFD) modeling to optimize hydrogen fuel cell design. By simulating internal flow paths, the team enhanced reactant distribution and startup/shutdown processes, resulting in improved performance and efficiency for industrial-scale applications.

Background

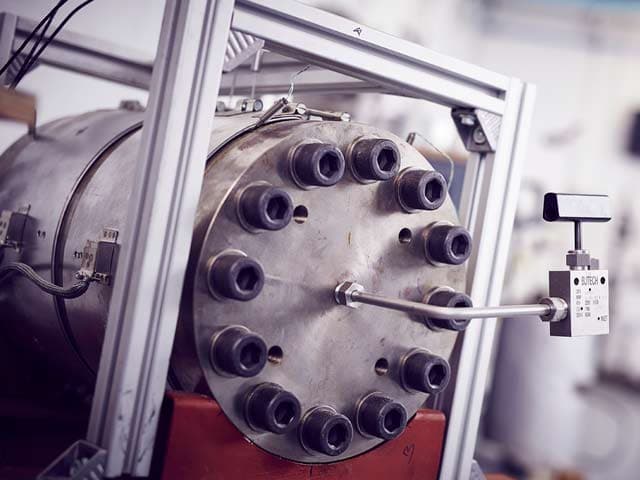

Hydrogen fuel cells generate electricity through the direct electrical reaction of hydrogen and oxygen within a cell, rather than by combustion. The only product is water, and so they provide a safe and environmentally friendly energy source for a wide range of applications. Element Digital Engineering were asked to provide design analysis support to the developer of an industrial-scale fuel cell. In particular, they were to help optimize the flow paths within the core of the cell.

The challenge

The performance of the cell in normal operation was governed by the effectiveness with which an optimum mixture of the reactants was supplied to the cell. Various manifolds and distribution systems fed the cell system, and our work was to ensure that the design of these fluid systems gave the best possible distribution. A secondary requirement was to ensure that the start-up and shut-down processes worked properly, again though optimizing the design of the various flow paths dedicated to those stages of the operation.

The solution

We used Computational Fluid Dynamics (CFD) to build a detailed 3D model of the device and simulate the flows and reactions within it. CFD divides the various volumes within the device into millions of small computational cells, within which the equations of fluid flow are solved. This model was then used to assess various changes to the design and automatically optimize the shape of key components. Over the course of the project (almost eighteen months), many models were built of specific components and operating scenarios.

The result

Through the use of our analysis, considerable advances were made to the design of the device and in particular to the start-up and shut-down.

To learn more about hydrogen fuel cell design analysis, or if you have any questions, contact our team today.

Why Choose Element

Industry-Leading CFD Expertise

Comprehensive Analysis

Cutting-Edge Methods

Collaborative Approach

Related Services

Hydrogen Testing

Element performs hydrogen testing, including hydrogen piping system and pipeline testing according to ASME B31.12, the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.