Protecting Proprietary Technology: How Element Created a Secure Testing Environment Without Compromising Client's Intellectual Property

Background

Battery management systems (BMS) are critical components in modern battery applications, controlling charging, discharging, and overall performance. For companies developing cutting-edge BMS technology, the controlling algorithms represent valuable intellectual property that provides competitive advantages in the marketplace. When one such company needed to validate their proprietary algorithm in real-world testing conditions, they faced a significant dilemma - how to test the technology thoroughly without exposing their IP to potential competitors.

The challenge

The client approached Element with an important request: they wanted to use Element’s comprehensive battery testing services, but couldn't allow anyone - not even Element's testing experts - to have access to their proprietary BMS algorithm. Traditional testing processes would typically require Element engineers to implement test parameters and monitor the system, which would inevitably expose the algorithm's functionality. Many testing laboratories had declined this project, considering the security requirements too complex to accommodate. Additionally, there were significant safety concerns, as battery testing carries inherent risks of thermal runaway and potential fires if not properly controlled.

The solution

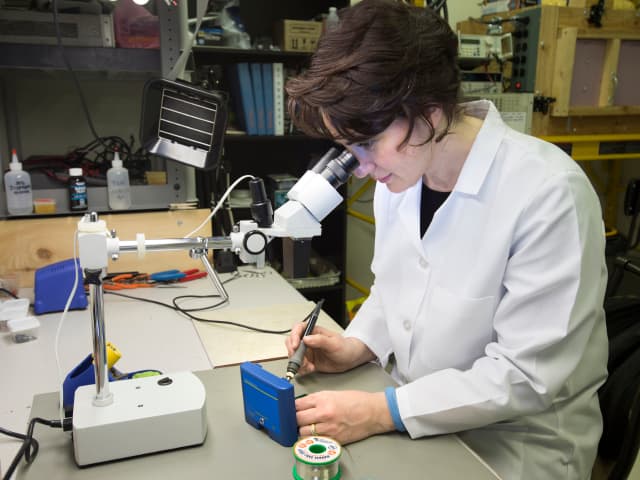

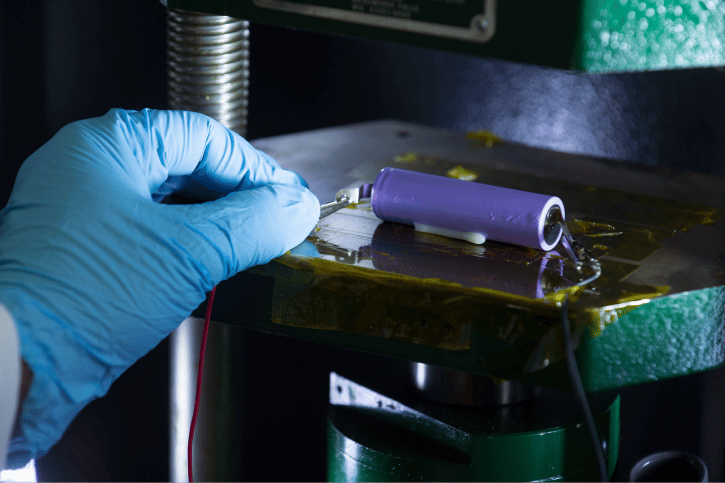

Element's engineering team proposed an innovative approach by creating a system that would allow the client to directly control our MACCOR battery cyclers through Raspberry Pi computers. The client would load their proprietary algorithm onto these small computers and connect them to our equipment, maintaining complete control over their intellectual property throughout the testing process. Element collaborated closely with both the client and MACCOR to design a secure process that protected the client's IP while ensuring that all safety protocols remained intact and couldn't be overridden. This required careful system design that separated control functions from safety parameters, creating a testing environment that was both secure and safe. Element's team served primarily as facilitators and equipment providers, giving the client unprecedented direct access to our advanced battery testing infrastructure while maintaining all necessary safety protocols.

The result

The implementation was a complete success, providing the client with the data they needed while maintaining absolute confidentiality of their proprietary algorithm. The Raspberry Pi integration worked flawlessly, allowing seamless control of the battery cyclers without compromising safety systems. The client specifically praised Element's problem-solving approach and willingness to take on a challenge that other testing laboratories had deemed too difficult or risky. This innovative solution has led to an ongoing partnership, with multiple subsequent testing programs successfully completed. The process developed for this project has now become a standardized capability at Element, offering similar intellectual property protection to other clients with sensitive technology. By creating this new testing methodology, Element has expanded its service offerings while reinforcing its reputation for solving complex customer challenges.

Why Choose Element

Custom Testing Solutions

Cross-Industry Expertise

Proprietary IP Protection

Collaborative Problem-Solving

View our Services

Battery Performance Testing & Competitive Benchmark Testing

Element's battery performance testing and competitive benchmark testing delivers accurate, real-world data on capacity, endurance, and discharge rates to help refine products, reduce risk, and support competitive market positioning.

Battery Failure Analysis

Element's comprehensive cell and battery failure analysis identifies failure modes and the root cause of product failure, providing the insights you need to design superior products.

Battery Safety and Abuse Testing

Element delivers advanced battery safety and abuse testing for various chemistries and formats, helping identify risks, support certification, and meet global standards across diverse industries and applications.