Arc Resistance Testing

Protect your critical insulating materials from electrical failure with precision ASTM D495 arc resistance testing. Identify potential tracking and carbonization vulnerabilities early, validate material performance under controlled high-voltage conditions, and safeguard your products against catastrophic electrical failures before they become costly problems.

What is Arc Resistance Testing at Element?

Arc resistance testing evaluates how insulating materials perform under high-voltage electrical stress. This testing is critical because electrical arcing—when a high-voltage discharge burns across or through an insulator—can lead to failure, fire risks, and serious safety hazards. At Element, we provide comprehensive ASTM D495 testing that subjects material samples to controlled electrical arcing, precisely measuring their ability to resist tracking, carbonization, and potential failure.

What Can Element Offer You For Arc Resistance Testing?

Key tests offered

Key tests offered

Standardized ASTM D495 arc resistance testing provides precision measurement of material breakdown points, tracking resistance, and electrical performance. Our testing methodology goes beyond basic screening to deliver comprehensive insights into material resilience under electrical stress.

Specific testing capabilities:

- Intermittent high-voltage arc discharge testing

- Surface tracking and carbonization analysis

- Material breakdown point identification

- Performance consistency validation

- Accelerated electrical stress assessment

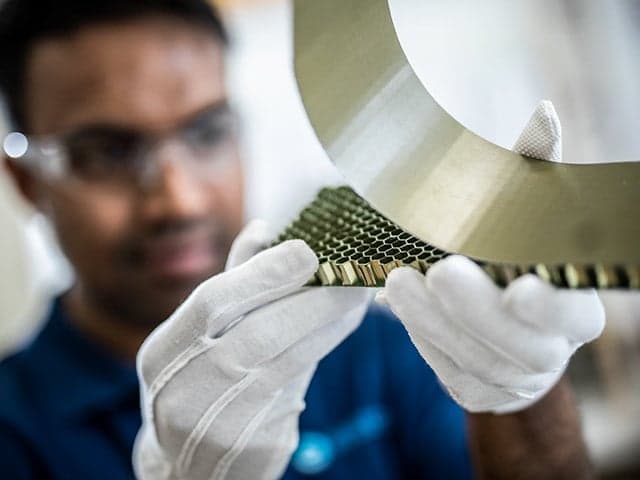

Materials we test

Materials we test

Comprehensive testing for a wide range of electrical insulation materials, offering in-depth analysis across multiple critical sectors. Our approach ensures thorough evaluation of materials' performance under high-voltage conditions.

Key materials include:

- Polymers and synthetic composites

- Advanced electrical insulation components

- Industrial and specialized insulation materials

- Electrical safety components

- Cutting-edge electrical engineering materials

Methods and solutions offered

Methods and solutions offered

Advanced testing methodologies simulate harsh electrical environments, providing detailed insights into material performance and potential vulnerabilities. We employ sophisticated techniques that progressively challenge materials by subjecting them to an intermittent high-voltage, low-current arc discharged along their surface. The time until failure modes like tracking, carbonizing, or ignition is precisely measured.

Key methodological approaches:

- Controlled electrical arcing simulation

- Precise time-to-failure measurement

- Systematic stress progression

- Comprehensive material screening

- Detailed performance documentation

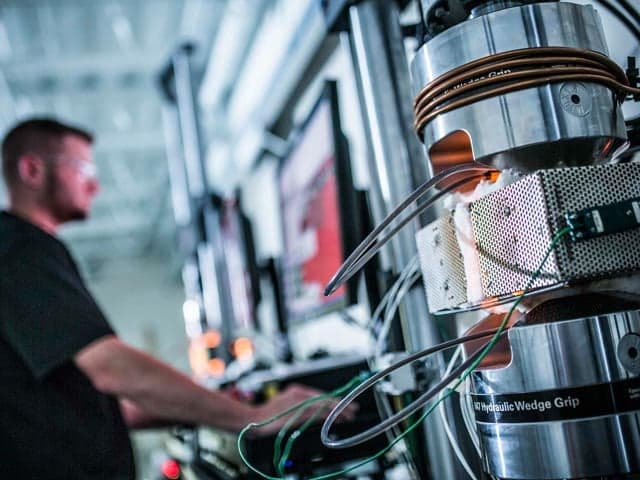

Cutting-edge equipment we use

Cutting-edge equipment we use

State-of-the-art electrical testing equipment enables precise high-voltage arc generation and detailed material performance analysis. Our technology allows for extremely accurate measurements of material electrical resistance and breakdown characteristics.

Equipment highlights:

- Advanced high-voltage arc generators

- Precision electrical stress measurement tools

- Environmental condition simulators

- Detailed performance tracking systems

- Sophisticated material analysis instruments

Specialized electrical safety insights

Specialized electrical safety insights

Deep technical expertise in understanding and mitigating electrical tracking and breakdown risks for critical insulating materials. Our approach combines decades of materials science knowledge with cutting-edge testing methodologies to provide unparalleled electrical safety insights that help prevent arc propagation and safeguard your products.

Standards we meet and the materials we test

- ASTM D495

- Additional international electrical safety standards

- Synthetic polymers

- Composite materials

- Electrical component insulators

- Advanced ceramic insulators

- Specialized industrial insulation materials

Your Challenges, Our Solutions

Preventing electrical failures

Validating material safety

Maintaining consistent quality standards

Reducing long-term electrical risks

Why Choose Element

Safety Validation

Early Detection

Quality Control

Time-Proven Approach

Frequently asked questions

How does arc resistance testing work?

A standardized method to evaluate insulating materials by subjecting them to controlled high-voltage electrical stress, measuring their resistance to tracking and breakdown.This testing helps you stay ahead of the curve and deliver premium insulating materials your customers can count on.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Materials Testing Services

View our comprehensive materials testing service range, combining destructive and non-destructive testing for a wide range of materials and industries.

Thermal Analysis Services

Element's thermal analysis services help identify material properties, anticipate changes, and reduce failure risks. Our experts provide accurate, reliable testing for polymers, composites, and advanced materials.

Composites Testing

Expert composite material testing with ISO 17025 accredited services. From raw materials to fatigue performance, get accurate results that enhance reliability and meet standards.

Mechanical Testing of Polymers

Element provides precise mechanical testing of polymers, delivering critical data on strength, resistance, and durability. Our expert analysis helps industries optimize material performance and maintain compliance.