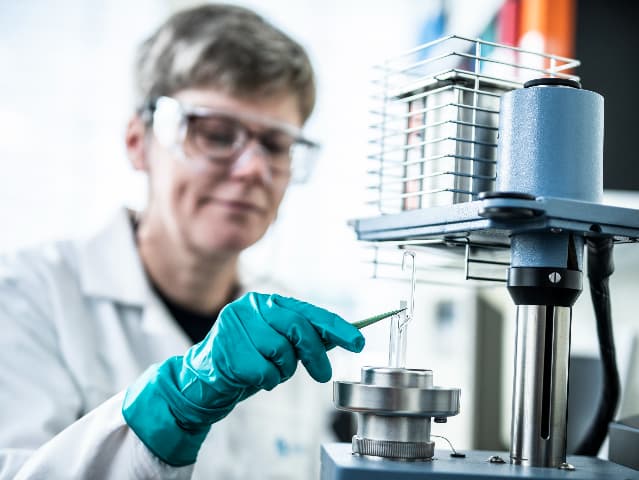

Dynamic Mechanical Analysis – DMA Analysis

Unlock precise material performance insights with Element's DMA analysis. From polymers to composites, our advanced testing capabilities offer end-to-end solutions, delivering actionable data on stiffness, damping, and thermal behavior. With global reach, hands-on technical guidance, and a full spectrum of standards, we ensure your materials meet the highest performance and reliability benchmarks

What is Dynamic Mechanical Analysis at Element?

Dynamic Mechanical Analysis (DMA) measures material properties by applying periodic stress to evaluate modulus (stiffness) and damping (energy dissipation). At Element, we provide insights into thermal and mechanical properties of non-metallic materials, helping you understand key performance parameters such as glass transition temperatures and deterioration limits.

What Can Element Offer You For DMA Analysis?

Key tests offered

Key tests offered

We deliver comprehensive material property measurements essential for understanding material behavior and performance. Our testing capabilities encompass the full spectrum of dynamic mechanical analysis, from basic property measurements to advanced characterization of complex materials under varied conditions. By measuring the response to oscillating force application, we provide detailed insights into your material's mechanical characteristics as a function of temperature, revealing crucial performance parameters for your application needs.

- Modulus and stiffness evaluation

- Creep and stress relaxation studies

- Film and tension behavior analysis

- Damping characteristics

- Glass transition and softening temperature determination

- Cure behavior

Materials we test

Materials we test

Our testing capabilities cover a wide range of materials, from composites and polymers to coatings and adhesives. We specialize in analyzing both solid and liquid materials, providing crucial data for material selection and optimization across multiple industries. This includes advanced composites, engineering plastics, rubbers, and specialized polymeric materials with complex mechanical and viscoelastic properties. We can measure how these materials respond to time, frequency, and temperature variations, ensuring accurate and reliable characterization for your specific application.

Methods and solutions offered

Methods and solutions offered

We offer both standard and customized testing protocols to meet your specific requirements, supported by state-of-the-art equipment and expert analysis. Our approach ensures accurate measurement of mechanical and viscoelastic properties across a wide range of temperatures and conditions. For advanced applications, we provide specialized analysis of stress-relaxation behavior and creep testing to give you complete understanding of your material's performance characteristics.

Advanced technical capabilities

Advanced technical capabilities

Our multidisciplinary team utilizes sophisticated DMA instrumentation to provide precise measurements across temperature ranges. We offer specialized testing for viscoelastic properties, time-dependent behavior, and advanced applications including stress-relaxation and creep testing including creep testing. Our capabilities allow for detailed analysis of material responses under various conditions, providing essential insights for material development and optimization. This comprehensive approach helps you understand fundamental transition temperatures and how they change with material formulation and conditioning.

Standards we test to and materials we test

American Society for Testing & Materials

- ASTM D4065

- ASTM D5023

- ASTM D5024

- ASTM D5026

- ASTM D7028

- ASTM E1356

- ASTM E1545

- ASTM E1640

Euronorm

- EN 6032

Institute for Interconnecting and Packaging Electronic Circuits

- IPC-TM-650

Society of Automotive Engineers

- SAE J2253

Various customer specifications

- SRM 18R-94, Sikorsky SS9152/PP101

Non-metallic materials

- Composites

- Polymers

- Coatings

- Adhesives

- Plastics

- Rubbers

- Solids and liquids with viscoelastic properties

Properties measured

- Modulus

- Creep and stress relaxation

- Film/tension behavior

- Damping

- Glass transition and softening temperature

- Cure behavior

Your Challenges, Our Solutions

Precise Material Characterization

Evaluating Complex Material Properties

Understanding Material Behavior Across Temperatures

Ensuring Compliance with Industry Standards

Why Choose Element

Global reach, local service

Comprehensive testing solutions

Industry-leading expertise

State-of-the-art technology

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Thermal Analysis Services

Element's thermal analysis services help identify material properties, anticipate changes, and reduce failure risks. Our experts provide accurate, reliable testing for polymers, composites, and advanced materials.

Thermomechanical Analysis (TMA)

Thermomechanical analysis (TMA) evaluates polymer thermal properties, including expansion and phase changes. Element provides precise data for R&D, quality control, and material classification.

Impact Testing of Polymers and Composites

Element's testing of polymers can enhance your product's durability, performance, reliability and safety across a range of industries.

Shear Testing

Get precise shear testing for adhesives, composites, and fasteners. Our specialized methods deliver accurate results for critical applications at any temperature.