Accelerating Mining Equipment Design: Development of a Fast-Solving, Physics-Based Comminution Model for a Global Mining Company

This case study details how Element’s Digital Engineering team developed a physics-based, reduced-order comminution model for a global mining company. By combining DEM simulations with machine learning, the solution accelerates crusher design optimization, improves energy efficiency, extends equipment life, and enables engineers to maintain consistent, high-performance rock crushing operations.

Background

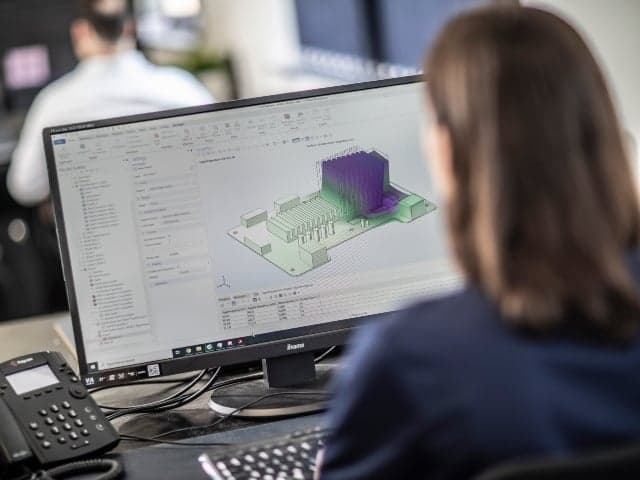

Crushed rock forms the foundation of our society. With growing demand for sustainability, the need for improving the performance and efficiency of rock crushing equipment is becoming increasingly important for mining companies. Element’s Digital Engineering team has recently worked with a global mining company to optimize the design of their rock crushing (or “comminution”) machines, to improve performance, enable energy efficiency, and extend lifetime estimates. To achieve this, our experts developed a physics-based, Discrete Element Model (DEM) of the mining equipment to enable a simulation of the crushing process. The DEM model allowed the team to simulate the rock breakage process of any given design, which allowed the customer to select the most efficient one for their needs.

The challenge

Unfortunately, the solution of this model required significant computational time and the team needed to assess a large number of design cases to optimize the setup. It was, therefore, essential to speed up the solution time. This was achieved by developing a Reduced Order semi-analytical Model (ROM) that combines physics-based breakage models with machine learning surrogate models, using impact data obtained from a reduced set of non-breakage DEM simulations.

The ROM uses a data science solution that utilized results from the DEM model simulations. We minimized the DEM model solutions required to provide sufficient data to the machine learning algorithm. This allowed the algorithm to develop relationships between the sizes of rocks that result from the changes to the input variables. The algorithm also assessed the impact that changes to input variables have on metrics such as machine wear. We used a Bayesian Design of Experiments technique to decide on the DEM simulations needed to train the ROM.

The solution

Once our client started using this technology, they inevitably asked the question, “Can we use it to optimize the design of a crusher?”. Our experts developed a solution to provide our client with answers to questions like “What inputs do I need to achieve a target output?” and “What inputs do I need to achieve a range of outputs when I’m uncertain about the exact value of some of the output quantities?”

The result

The resulting predictive tools allowed our client to confidently optimize their comminution machinery. The engineers can now quickly make changes to the operation of the in-service machinery to maintain consistent output. They can also easily develop new machines for future applications to sustain consistent production across their global operations.

Why Choose Element

Industry-Leading Expertise

Innovative Modeling Approaches

Sustainability Focus

Customized Problem-Solving

View our Services

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.

Finite Element Analysis (FEA) Services

Advanced Finite Element Analysis (FEA) services simulate product performance, optimize designs, and predict failures, addressing structural, thermal, and dynamic challenges across industries with expert solutions.

Discrete Element Method (DEM) Services

Model particle interactions, optimize processes, and improve equipment performance with our Discrete Element Method (DEM) services. Maximize efficiency today.