Engineering the Impossible: How Advanced Modeling and Additive Manufacturing Solved UKAEA’s Fusion Reactor Heat Exchange Challenge

This case study details Element’s collaboration with the UK Atomic Energy Authority’s STEP program to design a diverter heat exchanger for a fusion power plant. Element's Digital Engineering team partnered with HiETA Technologies to develop an additive-manufactured, recuperative heat exchanger optimized through advanced numerical modeling.

Background

The UK Atomic Energy Authority's (UKAEA) STEP program represents a groundbreaking initiative to demonstrate net electricity generation from fusion energy, positioning itself to become the world's first commercial fusion plant in operation.

The challenge

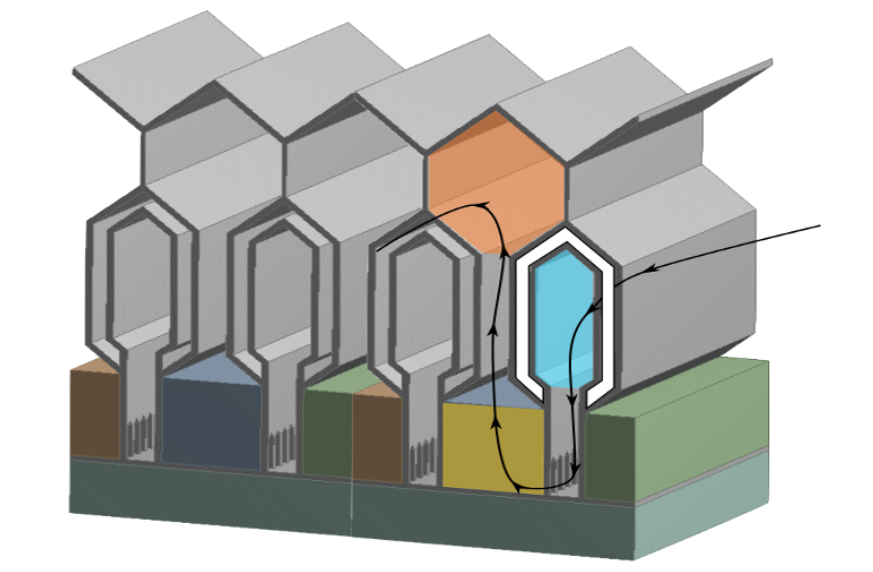

This clean energy frontier demanded innovative engineering solutions to overcome the extreme operational conditions inside a fusion reactor. The diverter region, which experiences the most intense heat loads within the fusion chamber, required a heat exchanger with exceptional thermal performance and durability. Designing a heat exchanger for a fusion reactor diverter presented numerous engineering challenges. The component would need to withstand extreme temperatures while efficiently transferring heat away from the fusion chamber wall. Any design would require careful optimization to balance thermal performance with mechanical integrity, ensuring adequate fatigue and creep life in this demanding environment.

UKAEA launched a competitive design process to find the most promising heat exchanger solution, seeking partners with advanced capabilities in thermal design, computational modeling, and innovative manufacturing approaches. Four companies would be awarded contracts, with the best design progressing to trial.

The solution

The Element Digital Engineering team have deep expertise in the use of numerical modeling for flow and thermal design. They entered the competition in partnership with HiETA Technologies, a product development and production company specializing in the use of metal 3-D printing, known as Additive Manufacturing (AM).

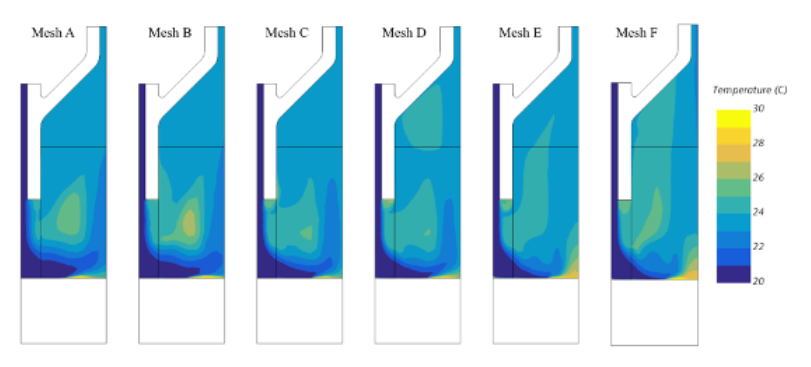

The diverter heat exchanger forms part of the wall in the very hottest part of the fusion chamber. HiETA’s expertise includes the use of AM for heat exchangers and the initial concept was for a complex, recuperative design achieved using AM optimized by in-depth numerical modeling and analysis. Intensive computational modeling honed in on a layout that would meet all aspects of the requirement – thermal performance, fatigue and creep life.

The result

The design and analysis work was completed sufficiently quickly that HiETA was able to produce a test piece within the overall three-month project duration. The design was judged to be the most promising of the four alternatives and is now in the test phase.

Why Choose Element

Proven expertise

Advanced computational modeling

Experience

Collaborative approach

Related Services

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.