From Lab to Line – How DRUM PEEL Enables In Situ Adhesive Joint Validation in Aerospace

This article presents Element's DRUM PEEL project, led by the Seville lab, focusing on evaluating adhesive bonds in composite structures under real service conditions. The project aims to develop a portable system for in situ characterization of peel and interlaminar fracture properties, enhancing quality control and design processes in industries like aerospace.

Background

Development of test tooling and procedure for in situ characterization of peel and interlaminar fracture properties

DRUM PEEL is a national project led by Element Seville. This project focuses on characterizing the behavior of different components joined by adhesives under service conditions. Evaluating the quality of bonded joints and determining parameters that define their mechanical behavior under fracture is crucial - not only for designers, but also for quality control during manufacturing processes.

The challenge

In the aeronautics industry and other technology sectors, the use of composite materials in primary aircraft structures is increasing. Additionally, bonded joints between composites are becoming more common than mechanical bolted joints. This shift requires a better understanding of how these joints behave under real-world loading conditions that may cause separation between the joined elements.

The solution

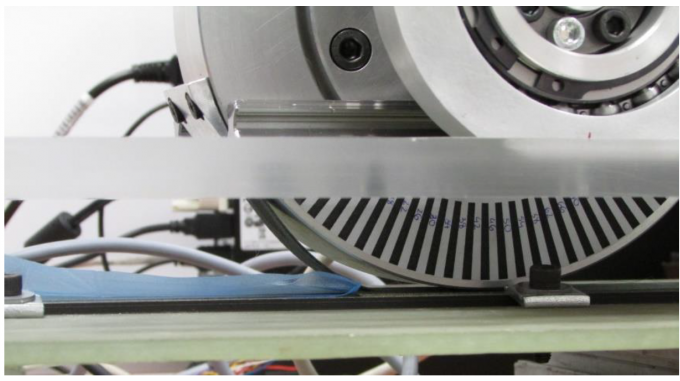

DRUM PEEL aims to develop a portable drum peel testing system capable of assessing interlaminar and peel strength in aircraft components joined with adhesives. This enables validation of aeronautical components directly on the manufacturing line, significantly reducing logistics and operational time. pioneered the use of drone technology to visually assess contamination in otherwise inaccessible areas, demonstrating our commitment to innovative problem-solving in complex environments.

Element Seville’s Role in the DRUM PEEL Project

As the sole project beneficiary, Element Seville was responsible for all DRUM PEEL tasks. The work began with researching the state of the art, identifying needs, and defining product requirements. Simultaneously, a stress analysis for the test setup was carried out through numerical modelling. This was followed by the design and manufacture of a prototype, and the definition and execution of both the validation system and qualification process.

The result

The project's results were disseminated as part of a specific work package, which included a patentability study for the developed device. The result was a unique piece of equipment in the current field of adhesive joint validation, reinforcing Element Seville's position as a reference laboratory in the European aeronautics industry.

The DRUM PEEL project was scheduled for 15 months, beginning in March 2017 and concluding in May 2018.

Funding entities: CDTI PiD EXP: 00098733 / IDI – 20170386; & CTA

Our Partners

Why Choose Element

Innovation Expert

End-to-End Project Ownership

Portable Testing Capability

European Industry Recognition

Related Services

Aerospace Mechanical Testing

View our range of aerospace mechanical testing services for both metals and non-metals - designed to help ensure that your materials are suitable for aviation use where failure is not an option.

Aerospace Composite Testing

Element provides testing in accordance with ASTM standards for polymer matrix composites and fiber-reinforced composite materials, for aerospace applications. Learn more about how our experts can assist your next project.

Aerospace Product Qualification Testing (PQT) Services

Explore Element's aerospace product qualification testing (PQT) services. Ensure safety, compliance, and efficiency with our global expertise and accredited capabilities.