Optimizing Hydrocyclone Performance: How Element Used CFD Modeling To Help A Global Mining Leader

This case study by Jon Douglas details how Element Digital Engineering applied Computational Fluid Dynamics to optimize hydrocyclone performance for a global mining client.

Background

In the competitive mining industry, efficient mineral processing is crucial for operational profitability. Our client, a major global mining company, was interested in understanding and optimizing the performance of their hydrocyclones.

Hydrocyclones are devices that use fluid pressure to generate a centrifugal force able to separate particles according to their weight. Generally, heavier particles are trapped in the underflow and the lighter particles go to the overflow. They are commonly used within the mining industry to process minerals, separating coarse and fine particles according to their size and density.

Element's Digital Engineering team have an excellent reputation for applying advanced simulation techniques to solve complex industrial challenges such as this one.

The challenge

With traditional trial-and-error methods often costly and time-consuming due to physical prototyping and testing, this challenge required a more scientific approach to understand and improve hydrocyclone performance.

Our mining client needed to understand the complex fluid dynamics within the hydrocyclone to improve separation efficiency, reduce wear, and optimize designs for specific mineral processing requirements. Key performance indicators - including pressure drop, water split ratio, cut size, and overall efficiency - needed accurate prediction methods. Additionally, the client required a solution that could model the three-phase interaction between water, air, and mineral particles of varying sizes and densities - a complex computational challenge that demanded sophisticated modeling techniques.

The solution

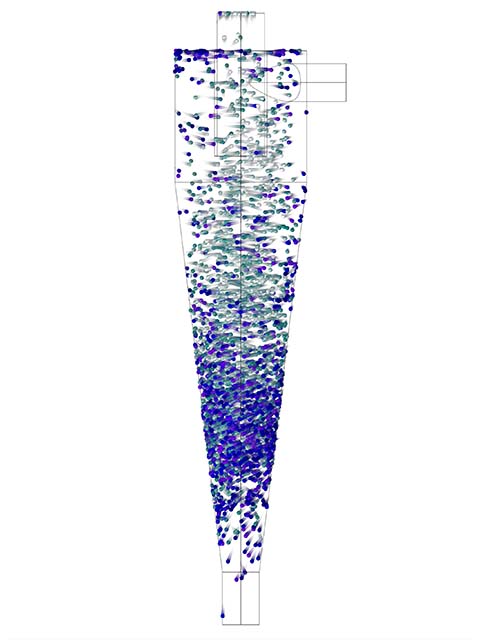

Element’s experts developed a Computational Fluid Dynamics (CFD) model of a hydrocyclone able to predict pressure drop, water split, cut size, and efficiency. The study of the hydrocyclone involved modelling the interaction between two continuum phases (air and water) and a discrete phase (particles). Good agreement was found between the base model predictions and the experimental data provided by the client.

The diagram demonstrates our hydrocyclone simulation model. Note that the heavier particles (represented in blue and purple) become separated from the lighter particles (represented in green and white).

The result

The simulation models that Element generated have been proven to be a reliable and cost-effective tool to optimize the performance and design of hydrocyclones within the mining industry.

Why Choose Element

Industry-Leading Expertise

Proven Simulation Methods

Cost-Effective Solutions

End-to-End Support

Related Services

Advanced Modeling and Simulation Services

Elevate your project with Element's modelling and simulation services, including fluid simulation, CFD, FEA, DEM, and electromagnetics. Our industry-leading expertise ensures precision, cost savings and regulatory compliance at every step.

Machine Learning and Data Science Services

Our Machine Learning and Data Science services offer customized solutions to transform your data into actionable insights. We integrate predictive analytics with hardware testing to minimize downtime, optimize resources, and improve safety. Our software-agnostic approach ensures seamless integration with your systems, delivering AI-powered insights tailored to your operational needs.

Concept and Feasibility Studies Services

Explore Element's Digital Engineering Concept and Feasibility Studies services, tailored to help you confidently navigate initial development phases, ensuring your ideas are feasible and robust.

Discrete Element Method (DEM) Services

Model particle interactions, optimize processes, and improve equipment performance with our Discrete Element Method (DEM) services. Maximize efficiency today.