Windmilling Testing Services for Aero Engines

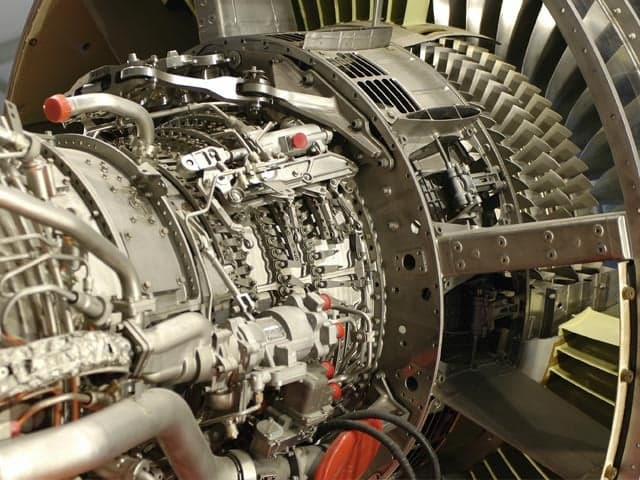

Avoid catastrophic incidents and ensure your aerospace systems meet the highest safety standards with Element’s precise and reliable windmilling and vibration testing. Our advanced capabilities simulate the extreme vibrations caused by fan blade-out events, validating the resilience and compliance of your engines and components. With cutting-edge equipment and proven expertise, we help you confidently address regulatory requirements, minimize risks, and optimize performance - keeping your projects on track, your customers safe and your reputation intact.

What is Windmilling Testing at Element?

Windmilling occurs when the propellor of an aircraft turns from airflow only, rather than powered by the engine. This could be due to a fan blade out event – such as ingestion of a bird by the engine – causing rotor blades to detach. The result is windmilling vibration, which often causes enough damage to halt power production, although the engine will continue to rotate due to the incoming airflow causing sustained engine imbalance - ‘windmilling’ - which places a significant strain on an aircraft’s flight systems. Windmilling testing ensures that these systems can handle the stress and remain operational.

While these extreme conditions are difficult to replicate in standard testing, Element’s LDS V8 electrodynamic test system can simulate even extreme events, providing the certainty you need to demonstrate your product’s compliance to any standard.

What can Element offer you for Windmilling Testing?

Products We Test

Products We Test

Element specialize in testing critical components such as aircraft engine fan rotors, flight system components, vibration isolation systems, and structural supports. Our expertise ensures every part of your system is validated under the most demanding conditions.

Key Services Offered

Key Services Offered

Our windmilling testing accurately replicates extreme stresses, providing reliable data to validate compliance with industry standards and confirm your systems' ability to operate under challenging conditions.

Cutting-Edge Equipment We Use

Cutting-Edge Equipment We Use

Simulating fan blade-out events involves high transient loads and sinusoidal vibrations (typically 5 to 25 Hz). Our powerful electrodynamic LDS V8 system is one of only a few in the UK and can accurately replicate these conditions, testing your systems under real-world stresses.

Which Labs We Offer This Service At

Which Labs We Offer This Service At

Our windmilling testing is conducted at our Warwick laboratory, one of the few UK facilities equipped with specialized high-displacement vibration testing systems. With globally recognized expertise, we’re positioned to support aerospace customers worldwide.

Products we test

- Aircraft engine fan rotors

- Engine mounts

- Flight system components

Your Challenges, Our Solutions

Replicating Extreme Real-World Conditions

Meeting Stringent Compliance Standards

Preventing Critical System Failures

Access to Cutting-Edge Facilities

Why Choose Element

Advanced Testing Capabilities

Trusted Industry Expertise

Compliance You Can Count On

Global Reach, Local Support

3,000+ Aerospace Experts

1of Few UK Labs

17025:2005UKAS Accredited

100+Years of Expertise

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Aerospace Engine Testing Services

Element’s aerospace engine testing provides reliable testing under extreme conditions, helping you optimize performance, reduce risks, and meet deadlines. Learn more.

Aerospace EMI/EMC Testing

Element's aerospace EMI/EMC testing helps you meet commercial and military standards with tailored test plans, advanced facilities, and expert guidance to tackle compliance challenges and reduce delays.

Altitude Testing Services

Access industry-leading altitude testing and high altitude simulation from -2,000 to 120,000 feet. Our combined environmental simulation integrates altitude pressure testing to cut costs and accelerate certification.

Aerospace Spin Testing Services

Make sure your rotating aerospace components perform safely at up to 200,000 rpm and 1,000°C. View our comprehensive spin testing solutions for manufacturers.

Explosive Atmosphere Testing and Certification

Element ensures your products comply with global explosive atmosphere testing regulations, including Global IECEx certification, ATEX certification for Europe, UKEX for United Kingdom, HazLoc certification for North America & DSEAR in the UK.

Dynamics Testing

Element's dynamics testing labs provide reliable, consistent data to the world's most critical industries. From aerospace to automotive to construction, we help ensure that your products are fit for purpose.

Lightning Strike Testing

Element's lightning strike testing helps your aircraft, infrastructure, and electronics withstand both direct and indirect lightning effects, reducing risk, supporting compliance, and protecting sensitive systems and materials. Learn More.