Hydrogen Testing

Facing challenges with hydrogen infrastructure? As hydrogen becomes crucial for clean energy, Element understand your material and system testing needs. From fuel cells to storage facilities and pipeline adaptation, cryogenic conditions to extreme pressures, and from fracture mechanics to permeation - our expertise ensures your hydrogen systems operate safely and efficiently. Element's technical guidance supports your evolving needs, whether you're developing new infrastructure or adapting existing systems for hydrogen-natural gas blending. We’ll help validate your components against hydrogen’s unique challenges.

What is Hydrogen Testing at Element?

Hydrogen testing is critical for validating your infrastructure's safety and performance in today’s evolving energy landscape. Our comprehensive testing ensures your systems can handle hydrogen's unique properties – from its high permeability to its potential for material embrittlement. Following ASME B31.12 standards and leveraging our evolving research in materials science and electrochemistry, Element’s experts help you prevent failures, verify material compatibility, and ensure operational safety across production, storage, and distribution systems.

What can Element offer you for Hydrogen Infrastructure Testing?

Key tests offered

Key tests offered

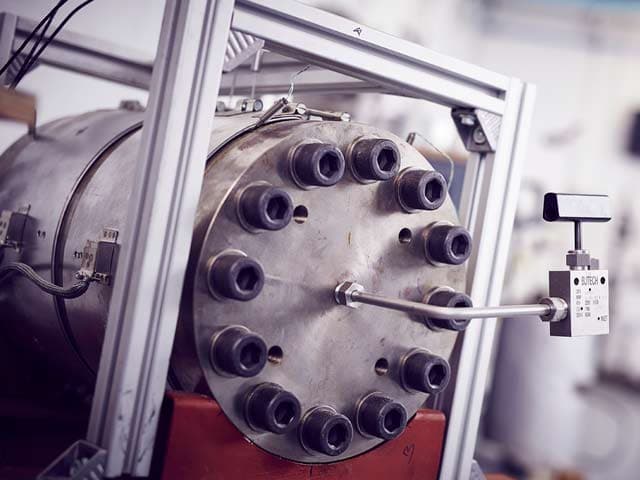

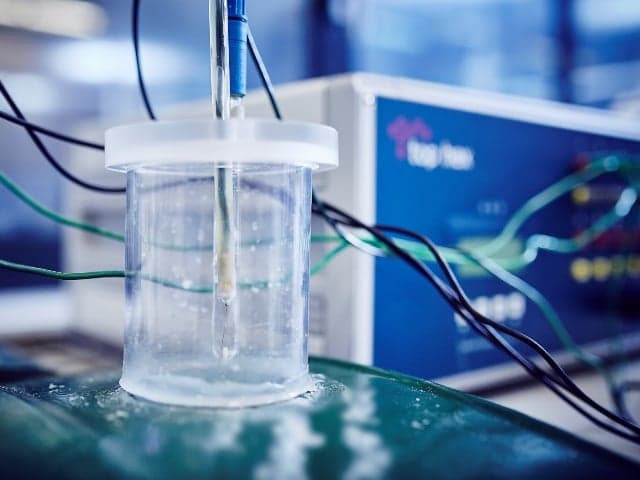

Element's comprehensive testing services focus on mechanical and fracture mechanics testing in hydrogen environments. We conduct permeation testing on elastomers and thermoplastics up to 100 bar, and cryogenic testing down to -268°C.

Including:

- Mechanical testing in H2 environments

- Fracture mechanics testing

- Permeation testing on polymers

- Cryogenic testing

- Pressure testing

- Material qualification testing

- Non-destructive examinations

- Leak detection

- Visual inspections

- Pipeline system testing

Components and materials we test

Components and materials we test

We specialize in testing materials and components critical to hydrogen infrastructure. Our expertise covers steel piping systems, elastomers, thermoplastic transmission lines, fuel tanks for aerospace and automotive, compressor seals, and carbon and low-alloy steels. Whether testing for green hydrogen produced from renewables or blue hydrogen with carbon capture requirements, we ensure materials perform under real-world conditions to prevent embrittlement and failure.

Methods and solutions offered

Methods and solutions offered

Building on decades of materials science expertise, we provide comprehensive mechanical testing and fracture mechanics-based design approaches for hydrogen containment and transport components. Our testing methods include constant displacement fracture mechanics testing per ASTM E1681 and ASME BPVC Sec VIII: Division 3- Article KD-1040, - a cost-effective, industry-preferred qualification method. We support both new infrastructure development and existing system adaptation, including the transition from natural gas or petroleum to hydrogen service.

This includes:

- Fracture mechanics-based design approaches

- Material characterization

- Qualification processes

- Pipeline conversion assessment

Testing covers materials and components in various conditions:

- Cryogenic environments (down to -268°C)

- High-pressure environments (up to 800 bar)

- Hydrogen-containing environments

- Mixed gas environments

- Environmental testing conditions

Which labs offer this service

Which labs offer this service

Our hydrogen experts in the UK, Texas and California support you from key energy hubs. Our unique facility for comprehensive gaseous and liquid hydrogen testing is the only one of its kind in the UK.

Standards we test to and materials we test

Piping system and pipeline testing

Element’s team of experts possesses extensive knowledge of the code content and demonstrated expertise in the field. With their profound understanding, they are adept at navigating through the requirements and conducting thorough assessments of Hydrogen Pipelines according to the ASME B31.12, ASME BPVC Sec VIII: Division 3- Article KD-1040, and ASTM E1681 standards.

Pipeline & Transport Systems

- Steel piping systems

- Gaseous hydrogen pipelines

- Natural gas pipelines (for hydrogen blend conversion)

- Distribution systems

- Transport infrastructure components

- Thermoplastic transmission lines

Storage Systems

- Liquid hydrogen storage tanks

- High-pressure gas storage systems

- Fuel tanks for aerospace

- Fuel tanks for transportation

- Storage facilities components

Metal Materials

- Carbon steels

- Low-alloy steels

- Weld materials

- Structural metals exposed to hydrogen environments

Non-Metallic Materials

- Elastomers (up to 100 bar testing)

- Thermoplastics

- Polymeric materials

- Seals (for compressors)

- Polymers for permeation testing

Carbon Capture Related

- CCUS project materials

- CO2 transport materials

- Materials exposed to trace gases

- Components for blue hydrogen production

Industry-Specific Components Automotive

- Fuel cell components

- High-pressure storage systems (750-800 bar)

- Small storage systems

Aviation

- Aircraft fuel systems

- Cryogenic storage components (-253°C)

- Aerospace tanks

Energy Supply

- Production plant components

- Distribution infrastructure

- End consumer delivery systems

- Pipeline conversion components

- Components for hydrogen-natural gas blending systems

Your Challenges, Our Solutions

Preventing Catastrophic Failures

Hydrogen Compatibility Challenges

Complex, Evolving Requirements

Adapting Existing Systems

Element Experts at your service

Why Choose Element

Decades of Materials Expertise

Complete Testing Range

Fracture Mechanics Leadership

Standards Development Experience

-268°CLowest temperature capability

100 barTesting pressure capability

30+years experience

8,500Expert engineers and technicians

But don't just take our word for it

See what others have to say about partnering with Element

Frequently asked questions

What is blue hydrogen and how does it affect material testing requirements?

Blue hydrogen is produced from natural gas with CO2 as waste product. When this CO2 is transported to underground storage sites for permanent carbon capture and storage (CCS), it creates unique testing challenges. Materials must withstand both CO2 and H2 at high pressures and temperatures, plus handle contamination from trace gases. Non-metallic seals and components must also be tested for rapid gas decompression (RGD) with CO2.

Why is hydrogen permeation testing important for polymeric materials?

Due to hydrogen's small molecular size, it permeates through polymeric materials much faster than traditional gases like methane used in fossil fuels. Testing is essential to calculate potential losses through transmission line walls and seals. Element quantifies these rates at pressures up to 100 bar and compares these permeation rates with previously tested gases to provide accurate loss predictions.

What specific pressures are required for automotive hydrogen storage testing?

Automotive hydrogen storage and fuel cell technologies require testing at particularly high pressures of 750-800 bar. These extreme conditions necessitate specialized testing protocols to ensure safety and reliability.

How does hydrogen pipeline testing differ from natural gas pipeline testing?

Hydrogen has different diffusivity and corrosivity properties compared to natural gas. This requires specific adaptations for production plants, transport infrastructure, and distribution systems, along with modified maintenance processes for hydrogen service.

What special considerations are needed for green hydrogen infrastructure?

Green hydrogen, produced using renewable electricity sources like wind or solar power, requires the same rigorous material testing as other hydrogen applications. However, the integration with renewable energy systems may introduce additional cycling requirements that need to be considered in material selection and testing protocols.

What is covered in the scope of ASME B31.12?

ASME B31.12 is the most comprehensive standard currently available for designing steel piping systems that carry gaseous hydrogen.

The code comprises several sections, including General Requirements and Industrial Piping, as well as Pipelines, which encompass distribution systems. These sections are tailored to address the unique considerations associated with hydrogen systems.

Notably, the code incorporates fracture mechanics testing and material performance factors that account for the potential detrimental impact of hydrogen gas on the mechanical properties of carbon and low-alloy steels operating within the hydrogen embrittlement range.

ASME B31.12 mandates that the pipe and its associated weld material must demonstrate sufficient resistance to fracture when exposed to hydrogen gas. The qualification process involves following the test method specified in ASME BPVC Sec VIII: Division 3- Article KD-1040, which in turn refers to ASTM E1681. This standard recommends the use of a constant displacement fracture mechanics test method, which is a cost-effective and relatively straightforward option for qualifying hydrogen transportation pipelines.

As a result, it has become a preferred choice in the industry for qualification testing purposes. Additionally, the Code introduces rules for the conversion or retrofitting of existing pipeline and distribution systems, allowing for the transition from natural gas or petroleum to hydrogen service.

Fracture and Fatigue Testing in Environment

In this Fracture and Fatigue video we explain how, through exposure, we analyze engineering components to determine their structural integrity.

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Rapid Gas Decompression (RGD) Testing

Prevent equipment failures with Element's pioneering RGD Testing, including first-ever H2S testing capability. Validate materials under realistic sour gas conditions for maximum reliability.

ASTM F519 Hydrogen Embrittlement (HE) Testing Services

Element's ASTM F519 hydrogen embrittlement testing evaluates material performance under tensile stress, identifying vulnerabilities in high-strength steels and alloys to prevent failures in aerospace, automotive, and energy applications.

Hydrogen Induced Cracking (HIC) Testing

Prevent critical equipment failure with our fast-turnaround Hydrogen Induced Cracking Testing. Expert NACE-compliant analysis ensures your oil & gas components are safe for sour service environments.

Sour Service Corrosion Testing for NACE MR0175/ISO 15156 Compliance

Element provides industry-leading sour service corrosion testing, helping oil and gas companies mitigate corrosion risks, comply with NACE MR0175/ISO 15156, and enhance material reliability in challenging environments.

Cathodic Disbondment Testing

Element's cathodic disbondment testing detects coating weaknesses before failure, simulating real-world conditions up to 204°C. Gain actionable insights to enhance protection for pipelines, offshore structures, and extreme environments.