The Dangers Of High-Altitude Ice Crystals: How Element Solved Critical Jet Engine Reliability Issues

Background

A leading aerospace manufacturer faced an issue affecting jet engine reliability at high altitudes. Moisture entering a pressure measurement line would freeze during ascent, disabling critical engine control functions. Ensuring accurate performance at all altitudes, particularly under transient conditions, was vital for safety and efficiency. The client approached Element due to our strong track record in computational modeling and aircraft icing solutions, supported by deep domain expertise and proprietary tools.

The challenge

The primary concern was to understand under what flight conditions the freezing would occur - and how quickly. Since moisture could infiltrate the line at low levels and solidify at high altitudes, the risk of engine control disruption was significant. The client needed a robust simulation that could replicate these scenarios and determine which specific profiles presented the greatest risk of blockage. Element were able to provide the detailed transient analysis capabilities required to explore these dynamics accurately.

The solution

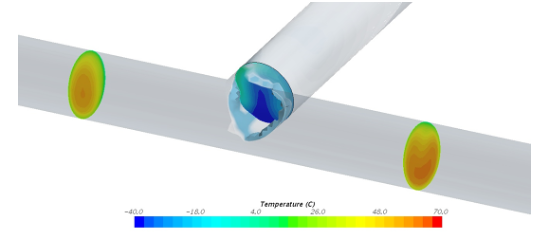

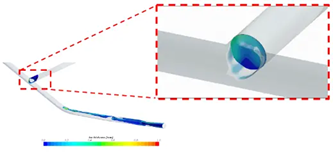

Element’s fluid dynamics team – which includes contributors to industry-standard Computational Fluid Dynamics (CFD) software - developed a transient CFD model, replicating realistic flight profiles. By simulating pressure changes, thermal gradients, and moisture behavior within the line, the model accurately reproduced the icing phenomenon. To reduce simulation time, less critical phases were intelligently accelerated without losing accuracy. Element leveraged our expertise in both CFD and aircraft icing - often tested under FAA and EASA protocols - to model ice formation, monitor crystal growth, and record the extent of blockages under varied conditions.

The result

Through our detailed CFD analysis, we made a crucial discovery that transformed the client's approach to the problem. The results clearly demonstrated that ice blockages were not inevitable but occurred only under specific combinations of atmospheric conditions and flight profiles. This insight allowed the client to implement operational protocols to minimize risk during these identified scenarios. More significantly, our team identified that a simple modification to the pressure line geometry would cause any ice formation to develop in a pattern that wouldn't result in complete blockage, maintaining integrity even when ice was present. This insight allowed the client to implement design changes without costly physical testing or redesign cycles. Element’s integrated CFD and icing expertise proved essential in diagnosing and mitigating this complex aerospace challenge.

Why Choose Element

World-Leading Icing Experts

Advanced Simulation Capabilities

Proven Problem-Solving Methodology

Time and Cost Savings

Related Services

Computational Fluid Dynamics

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

Aircraft Icing and Rain Test Methods

Element performs icing and rain tests to provide you with valuable data on product performance in extreme environmental conditions, helping you meet aerospace and military standards.