High Pressure High Temperature (HPHT) Testing

Ensure decades of material reliability in extreme environments with Element's world-class HPHT testing services. When your components face demanding conditions, our global network of specialized laboratories delivers precise performance data under your exact operating parameters. From qualification testing to custom programs, we help you select optimal materials, prevent costly failures, and maintain regulatory compliance—trusted by Energy, Aerospace, and Petrochemical leaders worldwide for critical applications.

What is High Pressure High Temperature (HPHT) Testing at Element?

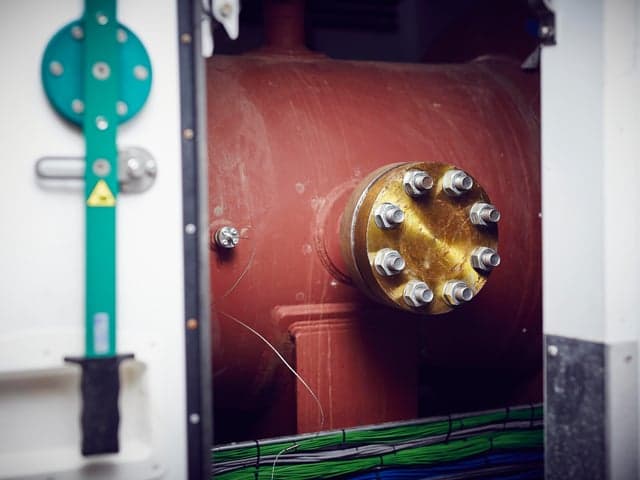

HPHT testing, also known as Autoclave Testing, simulates extreme service conditions by subjecting materials to high pressure and high temperature simultaneously. This critical evaluation process assesses how materials will perform in demanding real-world applications like oil & gas production and Carbon Capture Storage (CCS/CCUS). At Element, we replicate these harsh environments in controlled laboratory settings to evaluate the performance of metals, alloys, polymers, composites, and coatings, giving you actionable data for informed decision-making.

What Can Element Offer You For HPHT Testing?

Key tests offered

Key tests offered

Our comprehensive suite of HPHT testing gives you complete insight into how your materials will perform under extreme conditions, with specialized capabilities for both sour (H₂S-containing) and sweet (non-H₂S) environments. We subject your materials to specific combinations of liquids and gases, including H₂S, H₂, acids, bases, hydrocarbons, and custom mixtures while simultaneously applying relevant temperature variations and pressure fluctuations to replicate your exact operating conditions.

- Compatibility testing for polymers, elastomers, and composites

- Autoclave Slow Strain Rate (SSR) and Rippled Slow Strain Rate (RSSR) testing

- Cyclic pressure and temperature testing

- Custom exposure programs for material evaluation/qualification, and functional testing

- Custom exposure programs for client-specific applications

- Comprehensive pre- and post-exposure analysis

Materials and components we test

Materials and components we test

From critical sealing components to structural materials, we test a comprehensive range of items that must withstand extreme environments. Our testing capabilities cover elastomeric seals, gaskets, O-rings, flowlines, pipe liners, metal alloys, and composite materials used in high-stress applications. Whether you need qualification testing for a new material or investigating the cause of an unexpected failure, our experts deliver accurate, actionable results that help you select and validate materials for your most demanding applications.

- Polymer components: seals, gaskets, O-rings, flowlines, pipe liners

- Metals and alloys: pipes, connections, vessels, wellhead components

- Composite materials for structural applications

- Thermal insulation systems and coatings

- Critical components for subsea and downhole applications

Methods and solutions offered

Methods and solutions offered

Our experts work with you to advise on the most suitable testing methods for your materials, develop testing protocols that meet your specific project requirements, and build custom R&D programs to evaluate components and systems. We optimize resource allocation by using adaptable testing platforms with multiple large vessels and smaller units, enabling simultaneous testing and faster results. For polymer testing, we offer specialized capabilities for both sour (H₂S-containing) and sweet (non-H₂S) environments with test durations ranging from standard protocols to extended exposure studies.

- Qualification testing to industry standards

- Custom testing programs for specific applications

- Accelerated aging to predict long-term material performance

- Rapid Gas Decompression (RGD) evaluation in both sour and sweet environments

- Sour and sweet fluid compatibility testing

- Failure analysis for in-service components

- Comprehensive material characterization before and after exposure

Post-Exposure Services:

Following HPHT testing, Element provides a comprehensive suite of post-exposure services to assess material properties and identify potential degradation mechanisms:

- Chemical Analysis (FTIR): Identify before and post-test material composition and degradation products.

- Thermal Analysis (TGA/DSC): Assess thermal stability, decomposition behavior, glass transition, crystallinity through combined weight and heat flow measurements.

- Thermo-Mechanical Properties (DMA): Measure changes in material properties such as stiffness, modulus, and damping characteristics as a function of temperature, time, and frequency before and after HPHT exposure.

- Thermal conductivity measurement: Assess the impact of HPHT exposure on a material's thermal conductivity, a critical factor for heat transfer applications.

- Electrical Properties: Evaluate changes in electrical conductivity and other electrical properties after HPHT exposure, relevant for electrical components.

- Microscopic Analysis: Employ optical and electron microscopy to examine the microstructure of the material and identify any microstructural changes induced by HPHT exposure.

- In-Situ Friction Testing: Assess the tribological properties of materials under simulated downhole or service conditions. This test replicates the specific temperature, pressure, environment, media, force, and speed experienced by the material in real-world applications. By measuring the coefficient of friction and mass losses of materials under these conditions, you gain valuable insights into the material's ability to perform reliably in terms of wear and tear.

- Mechanical Testing: Evaluate changes in material properties like flexural, tear, tensile strength, yield strength, and elongation after HPHT exposure.

Cutting-edge equipment we use

Cutting-edge equipment we use

Our state-of-the-art facilities are equipped with specialized testing vessels and analytical equipment to simulate the most demanding service environments and accurately measure how materials respond to these challenges. We operate multiple large HPHT vessels, allowing for simultaneous testing and faster turnaround times. Our specialized equipment includes vessels capable of extreme conditions (up to 2000 bar, 320°C), dedicated facilities for sour service testing, and comprehensive analytical capabilities for post-exposure evaluation.

- Multiple large HPHT vessels for simultaneous testing up to 2,000 bar and 300°C

- Specialized vessels for testing up to 320°C

- Dedicated facilities for sour service testing with mixtures containing up to 30% H₂S, performed in sealed areas with fast extraction systems to ensure safety

- Pressure labs with over 100 test stations for sweet environment testing

- Comprehensive analytical equipment for post-exposure evaluation

- Simulated Service Test (SST) vessel for pipeline insulation testing

Element uses a fully instrumented 0.8 m diameter SST (Simulated Service Test) vessel for two 5 m insulated pipes capable of being heated to 200°C internally with up to 250 bar external water pressure at 4°C for tests lasting up to 12 months. Our experts can thoroughly assess subsea wet insulation coatings for changes in mechanical and thermal properties caused by the simulated service conditions.

- Low-temperature seal performance rigs

Our sour fluid exposure capabilities

- World-class scale sour fluid exposure facilities in the UK and the US.

- Routine exposure to 340 bar and 250 °C with mixtures containing up to 30% H₂S

- Exposure temperatures to 320 °C in special vessels.

- Customer-specific services; consultancy, material and functional testing programs.

- Rapid Gas Decompression (RGD) tests with sour gas mixtures.

Our sweet fluid exposure capabilities

- Pressure labs with over 100 test stations

- Our standard vessels operate up to 230°C and 1000 bar

- Special vessels are used for temperatures to 315°C and pressures to 1,400 bar

- Pressure labs with over 100 test stations

- Low-temperature seal performance rig

- Dedicated rigs for umbilical pressure cycling and permeation (ISO 8308)

- Dedicated lab for gas permeation

- Many ovens for vapor pressure tests

- Simulated Service Test (SST) vessel, for pipeline insulation

- Customer-specific services; consultancy, material, and functional testing programs

Which labs offer this service

Which labs offer this service

Element operates world-class HPHT testing facilities strategically located to serve global clients, with specialized capabilities at each location. Our extensive network provides convenient access to testing services regardless of your location, with consistent methodologies and documentation across all facilities. Our technical staff have contributed to both ISO and NORSOK standards development and are members of the relevant ISO Working Group committee. Element has also run two internationally supported Joint Industry Projects (JIPs) in the area of oilfield polymers: SOUR and SOUR2. With laboratories in the UK, US, and Europe, we offer localized support with global expertise, ensuring you receive the same high-quality service and reliable results wherever you are based.

- UK: Advanced polymer testing facilities including sour service exposure capabilities

- US: Global Corrosion and Materials Technology Center in Houston specializing in metals and polymers

- Europe: Specialized testing facilities supporting the energy sector

- Additional support from our global network of laboratories for comprehensive materials evaluation

Standards we test to and materials we test

- ISO 23936-1 (Thermoplastics) and ISO 23936-2 (Elastomers)

- NORSOK M-710 (Elastomers and Thermoplastics)

- API 6A (ISO 10423) F.1.11 & F.1.13

- NACE MR0175/ISO 15156

- NACE TM0187, TM0296, TM0192, TM0297

- API 17D (ISO 13628-4)

- ISO 12736, ISO 8308

- ASTM G48

Material qualification tests involving sour fluids are described in the following standards:

- ISO 23936-1: Thermoplastics

- ISO 23936-2: Elastomers

- NORSOK M-710: Elastomers and Thermoplastics

- ISO 10423 F.1.13 (API 6A)

- Fixture and immersion test to class DD/EE and FF/HH

- NACE TM0187 - Evaluating elastomer materials in sour gas environments as per NACE TM0187

Material qualification tests involving sweet fluids are described in the following standards:

- NORSOK M-710 / ISO 23936

- ISO 23936-1: thermoplastics; durability

- ISO 23936-2: elastomers; durability and RGD

- NORSOK M-710: durability and RGD (elastomers); durability (thermoplastics)

- Other RGD Standards

- ISO 13628-2 API 17J “Specification for Unbonded Flexible Pipe”

- Shell ED Test Procedure

- Total GS PVV 142 Appendix 8 “Elastomer O-ring Seals Explosive Decompression Type Testing Procedure”

- NACE TM0192 “Evaluating Elastomeric Materials in Carbon Dioxide Decompression Environments”

- NACE TM0297 “Effects of High-Temperature, High-Pressure Carbon Dioxide Decompression on Elastomeric Materials”

- ISO 10423 F.1.11 & F.1.13 (API 6A)

- Appendix F.1.11 Pressure / Temperature Cycling Test

- Appendix F.1.13 Fixture and Immersion Test

- We perform high-pressure temperature cycling and sub-ambient portions of the fixture tests in a dedicated cold box.

- ISO 13628-4 (API 17D)

Section 5.1.7.7 Life-cycle/endurance testing

The 200-cycle pressure test is performed on valves, chokes, and actuators in specified conditions, for example, at room temperature with water.

- ISO 13628-5

Sections 7.3.7.12.3 Pressure cycling and 7.3.7.13 Permeation

- ISO 8308

Permeation of liquids through hose and tubing walls umbilicals

- ISO 12736

Assessment of the thermal, physical and mechanical performance of thermal insulation coating materials on pipes, field joints, and components.

Polymeric materials

- Elastomers (O-rings, seals, gaskets)

- Thermoplastics (flowlines, pipe liners)

- Composites (structural components)

- Thermal insulation materials

- Coatings and liners

Metallic materials

- Corrosion-Resistant Alloys (CRAs)

- Carbon steels

- Stainless steels

- Nickel-based alloys

- Specialty metals for extreme environments

Your Challenges, Our Solutions

Material reliability through precise testing

Real-world conditions replicated accurately

Regulatory compliance made straightforward

Long-term performance precisely predicted

Element Experts at your service

Why Choose Element

Unmatched HPHT expertise

Standards development leadership

Comprehensive testing capabilities

Global accessibility with local support

25+years

100+

30+years

2000 bar, 320°C

Frequently asked questions

What's the difference between sour and sweet environment testing?

Sour environments contain hydrogen sulfide (H₂S), a toxic gas present in many fields throughout the world, sometimes at very high levels. H₂S can cause additional chemical aging and deterioration in materials, particularly polymers. Sweet environments are non-H₂S containing. Element offers specialized testing for both environment types with different test protocols and safety measures, ensuring seals and other polymeric components are specified and qualified appropriately to established international standards

Explore our global network of labs and find your nearest location

VIEW ALL LOCATIONSRelated services

Rapid Gas Decompression (RGD) Testing

Prevent equipment failures with Element's pioneering RGD Testing, including first-ever H2S testing capability. Validate materials under realistic sour gas conditions for maximum reliability.

Thermal Insulation Coating Testing

Element provides advanced thermal insulation coating testing for subsea pipelines, delivering precise data on durability, corrosion resistance, and compliance with industry standards to support material performance and longevity.

Electrochemical Corrosion Testing

Element offers electrochemical corrosion testing to identify material risks, enhance durability, and support informed material selection across industries.

Polymer Testing & Characterization Services

Maximize your polymer material performance with Element's comprehensive testing services. Our expert analysis translates complex data into actionable insights across your entire product lifecycle.

Pitting and Crevice Corrosion Testing

Element provides pitting and crevice corrosion testing to assess material durability, identify hidden vulnerabilities, and support industry compliance using advanced testing methods tailored to real-world environmental conditions.

Stress Corrosion Cracking (SCC) Testing

Element's stress corrosion cracking testing identifies material vulnerabilities early, preventing sudden failures. Our specialized analysis replicates real-world conditions to enhance reliability, safety, and compliance across critical industries. Learn More.

Dynamic Mechanical Analysis – DMA Analysis

Element offers DMA testing to analyse thermal and mechanical properties of non-metallic materials. We provide insights into stiffness, damping, and glass transition to enhance material performance.

Thermal Vacuum Testing Services

NASA-recognized thermal vacuum chamber testing for space components. Simulate extreme environments with precision temperature cycling and high vacuum. Prevent costly failures before launch.